Groupe Gorge, the parent company of 3D printer manufacturer Prodways, has reported financial results for 2016. Today’s report also announces plans to bring new additive manufacturing metal technology to market.

During last year’s Rapid event Prodways launched their sub €100,000 laser sintering 3D printer, the ProMaker P1000. The launch was accompanied by news of strategic partnership with chemical company, BASF. The deal sees the PA6 powder for SLS and developed by BASF, LSS, Hunan Farsoon Tech Ltd and Varia 3D integrated with other materials offered by Prodways. PA6 has particular application for the additive manufacture of functional components.

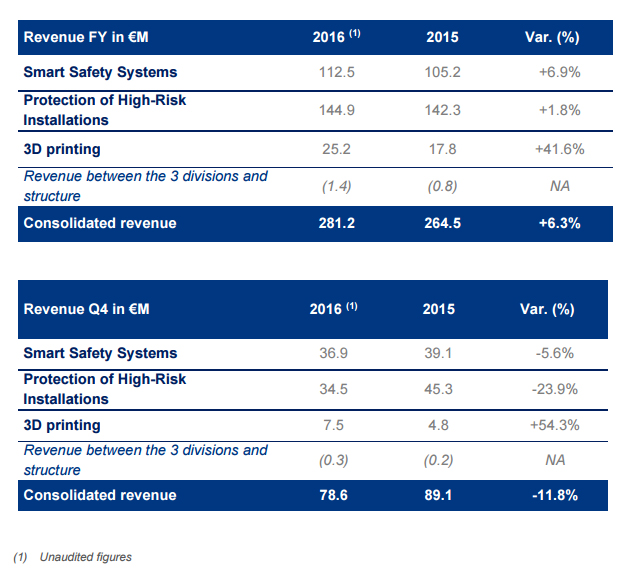

Groupe Gorgé segment revenue across Smart Safety Systems, Protection of High-Risk Installations and . Consolidated revenue across the group has increased by €15.82 million year on year. Of the three divisions, contributes a fraction of the two larger and more well-established businesses, however it is fastest growing with a 42% increase during 2016 reported.

Strategic focus for 2017

Total revenue from 3D printing was €25.2 million for 2016 and consolidated revenue across the group €281.2. Groupe Gorgé are satisfied with these numbers and say, “consolidated revenue exceeded the announced objective at €281.2 M, up by 6.3%.”

Commenting on the 3D printing business unit a company spokesperson said,

The 3D printing division performed well in the last quarter, with growth of 54.3% at €7.5 million, to end the year with growth of 41.6% (€25.2 million compared to €17.8 million in 2015). The Systems business (printers and materials) generated €13.1 million in revenue, up by 22.2% and the Products activity (parts sales) €12.1 million, up by 68.9% (in 2015, the Initial subsidiary was consolidated only over 9 months).

As with other OEM’s in 2016 strategy turned towards identification and deepening the application and end use of 3D printing. For Groupe Gorgé this involved increasing the range of 3D printers, “to address and better serve specific markets.” The company explain that strategic focus on healthcare remains core as, “The division continues to develop applications in the medical sector, particularly in the manufacture of 3D printed parts for this sector and more specifically for dental and chiropody applications.”

New metal 3D printing technology for 2017

Looking forward to the coming year the company have some interesting news coming up. In addition to increasing market penetration for the ProMaker P1000 they have also announced, “New proprietary technologies for metal 3D printing machines” are in development.

To stay up to date with all the latest 3D printing industry news, sign up to our newsletter and follow us on social media.

Leave A Comment