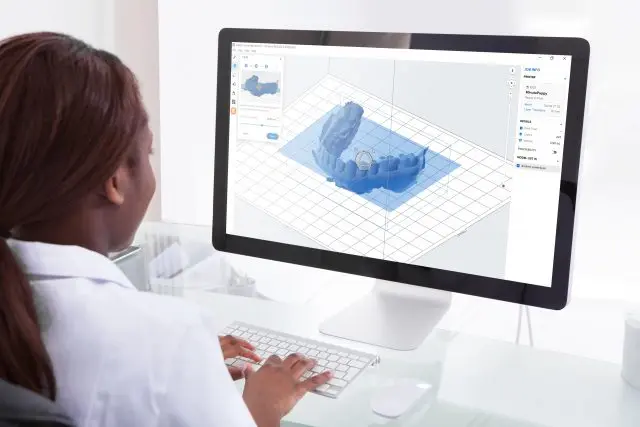

Formlabs is introducing Scan to Model, a new feature in its PreForm software that is designed to convert intraoral scans into easily 3D printable models. Dental professionals can use Scan to Model as an entry point into digital dentistry workflows without having prior experience with digital dental design software.

Creating diagnostic, formed appliance and fit check models is simple, and takes less than an hour: users scan a patient’s teeth with a 3D intraoral scanner, upload the raw model into PreForm’s Scan to Model tool, and then print with a Formlabs Form 3B printer.

Before Scan to Model, technicians that completed 3D scans of patients’ teeth using an intraoral scanner would have to be well-versed in complex dental CAD software, use open-source mesh editors not designed for the needs of dental professionals, or outsource this processing to a dental lab.

Manufacturing on Demand

The software now enables dentists to reduce the effort required to turn a 3D intraoral scan into a simple printed model and reduce overall turnaround time for models and retainers, enabling same-day delivery. All with a reduced number of software programs required to perform simple model preparation.

PreForm is Formlabs’ free software that uses advanced, proprietary calculations to generate supports and optimize print settings for each printed part. Each installation of PreForm also includes the latest version of the Formlabs printers’ firmware, which can be updated at any time to stay up to date.

PreForm’s automatic algorithms set up the print’s layout, orientation, and supports, so anyone can print successfully without specialized training. Expert users can manually adjust a variety of parameters, such as support density and size, to fine-tune results and use advanced print mode to selectively vary layer thickness throughout printing, balancing high detail and high speed.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Victor Anusci

Leave A Comment