Ford Motor company, the first company to ever successfully mass produce a product via assembly line manufacturing, has partnered up with “Silicon Valley’s Printer”, which is a phrase used by Carbon3D CEO Joseph DiSimone to describe his Sequoia-backed ultra-fast 3D printing startup.

We just finished reporting on the latest Carbon3D news, which revealed that Hollywood company Legacy Effects is now using Carbon3D CLIP technology to speed up the efficiency of prop delivery to under 24 hours. Legacy Effects used their Carbon3D prototype to build props for a Progressive Insurance commercial, as well as for some unnamed and unseen special effects for the Terminator: Genisys movie.

Ford had recently teamed up with TurboSquid, releasing 3D models of various vehicles to the public for 3D printing purposes. The former CEO of Ford, Alan Mulally, also joined Carbon3D’s board of directors. And we know that Ford has developed its own additive manufacturing research program.

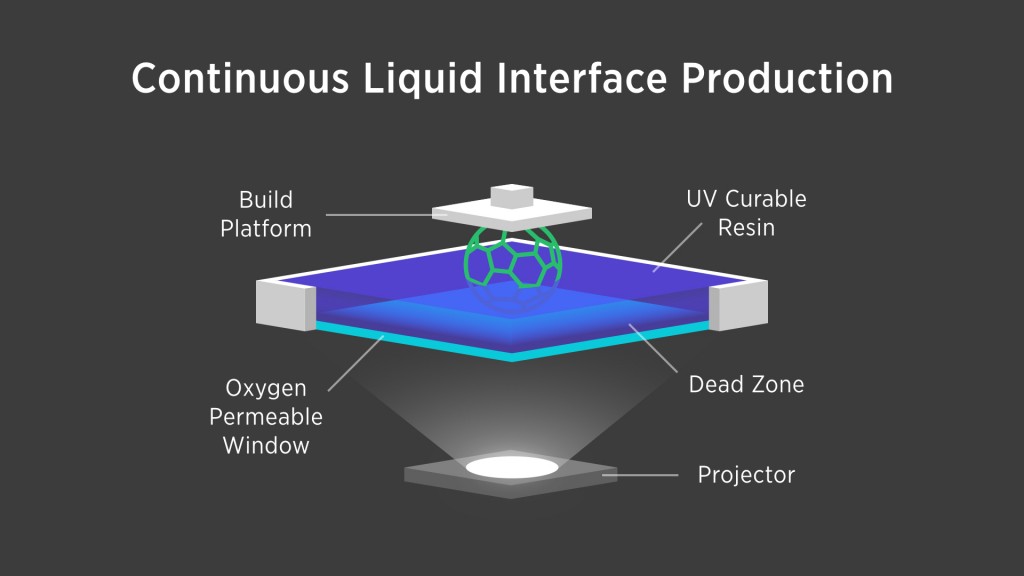

Now, we know that Carbon3D had actually gone to the auto manufacturer in 2014 to demonstrate their rapid CLIP technology. Ford was interested and, so, Carbon3D offered them a prototype and membership in their early access program. As a result, the Ford research team was off to the races. The goal at Ford is not only to create and develop new methods of expediting the prototyping process, but to also 3D print finished parts that can be integrated directly into their vehicles on the factory floor.

Ellen Lee, the team leader in additive manufacturing research at Ford, said, “If we can shave months off of production time and get a new model onto the market earlier, we can save millions.” Lee added, “It was really exciting to see the resulting mechanical properties. There were a lot of things we saw in the technology that would address the main challenges, and we decided to investigate.”

Ford is a perfect company to test the pre-release version of Carbon3D’s first device. According to a recent blog post from Carbon3D, Ford would be able to “evaluate its ability to produce commercial-quality polymeric parts by unlocking mechanical properties unattainable with any other 3D printing technology.”

So, what did Ford make with the Carbon3D prototype? Ford has “grown” (3D printed) elastomer grommets for the Focus Electric, which protect wiring inside a vehicle door from being damaged when the door is in motion, opening and closing. They tested and compared the grommets against others manufactured using conventional 3D printers. How did the Carbon 3D grommets fare? Well, they were created much faster, being fully formed 66% faster and with material properties that were a closer match to the desired properties of the final, ideal grommets.

In another project they tested a few different damping bumper parts for the Ford Transit Connect. The ultra-fast CLIP process reportedly facilitated a sped up iterative process versus traditional methods, but it is not known if “traditional methods” refers processes like injection molding or traditional 3D printing methods. Though, it is likely that “traditional” does refer to non-additive technologies.

Another interesting way Carbon3D has helped Ford’s additive manufacturing research team is by facilitating materials research. Since Ford’s AM team got their hands on the Carbon3D prototype, they’ve tested a few different materials, including “resins reinforced with nano-sized particles”. They’ve expressed interest in making resin modifications to strengthen the output of materials with desirable mechanical properties, including the exploration of materials with thermal and electrically conductive properties.

Carbon3D electrified the industry when Joseph DiSimone made his TED 2015 talk announcing the entry of CLIP technology into the ever expanding and contracting 3D printing industry. With the recent news of Legacy Effects and, now, Ford using the unique printing process, it wouldn’t be surprising to see the Carbon3D tech being used in even more places in the near future.

Leave A Comment