Ford announced this week that plans to invest in a Mexican automotive production plant are cancelled. The automotive maker will instead expand an existing site in Michigan. Ford CEO Mark Fields revealed plans to build a $4.5 billion series of facilities as part of a five year investment plan. The plan will see Ford pivot towards manufacturing in the United States.

The plan includes creating new electric vehicles and implementing wireless car charging. Investing in advanced manufacturing in the U.S. will also include 3D printing technology.

Donald Trump

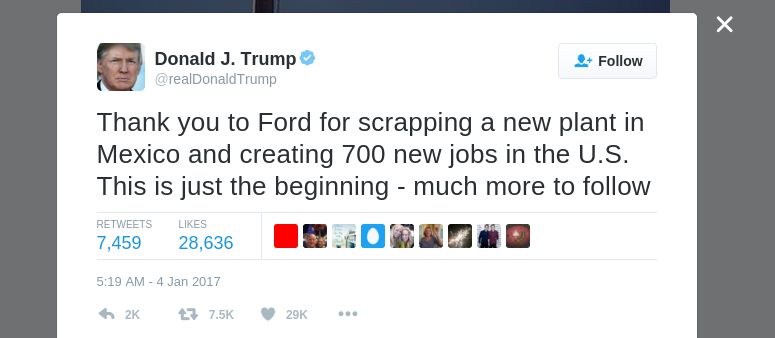

Donald Trump criticized the American automotive company for outsourcing manufacturing. It is believed that the president-elect had a heavy influence on the decision. Ford CEO Mark Fields revealed one of the factors was the “more favorable US business environment that we see under President-elect Trump and some of the pro-growth policies that he’s been talking about.”

Fields also cited a decrease in demand for smaller vehicles of the type planned for non-domestic production.

Ford and

Ford regard themselves as one of the earliest adopters of 3D printing. The company purchased the ‘3rd Stereolithography machine ever made’ back in 1988 according to Joy H. Forsmark, a technical expert at Ford Motor Company Research and Advanced Engineering Laboratories.

The car manufacturers currently produces approximately 225,000 3D printed parts a year, in the main for prototyping and research purposes. The company have 5 Global Rapid Manufacturing and Research Centers around the world utilizing AM technology, according to a company source. Ford are partners with 3D printing company Carbon and also Stratasys. Ventures that aim to incorporate 3D printing into their manufacturing process and is therefore likely that Ford will be incorporating 3D printing as part of this multi-billion dollar investment.

As seen at trade shows during the past year Ford are exploring how new the Stratasys demonstrator technologies, Infinite Build and Robotic Composite can be incorporated into their automated production lines. These 3D printing methods have potential to be used in advanced manufacturing facilities or in the Industry 4.0 enabled factories of the future.

Plans for the future

The planned investment will see an initial $700 million used to upgrade Ford’s Flat Rock Assembly Plant in Michigan. This will create 700 new jobs.

Ford aim to produce 13 new electric vehicles. This includes plans for wireless car charging, direct competition with Tesla’s supercharger ports. Ford will build a hybrid V8 engine in order to power a new hybrid Ford Mustang. Prototyping these vehicles will utilize the advantages conferred by 3D printing.

CEO Mark Fields speaking at the Michigan plant said,

“Our investments and expanding line-up reflect our view that global offerings of electrified vehicles will exceed gasoline-powered vehicles within the next 15 years.”

Nominate Ford or another company using 3D printing in the 1st Annual Industry Awards here.

Featured image shows the 2017 Ford Mustang. Image via Ford.

Leave A Comment