Farnborough International Airshow in the UK gets underway today and GE Additive has chosen the occasion to make two announcements.

Farnborough International Airshow (FIA) is the second largest airshow in the world, and as such will feature many of the leading applications of industrial 3D printing for the sector. Industry will be at FIA all week to bring you news direct from the event.

GE Additive signs agreement with Eaton

The first announcement from GE Additive is an agreement with Eaton regarding the purchase of two Concept Laser additive manufacturing systems. Eaton, headquartered in Dublin, Ireland, is a power management company. Sales at the company in 2017 reached $20.4 billion.

Eaton Aerospace Group’s industrial 3D printing strategy will be supported by this investment in the Concept Laser systems. Furthermore, AddWorks industrialization consultancy services will be provided by GE to support the integration of the systems into the company’s long-term additive manufacturing strategy.

Jason Oliver, President and CEO, GE Additive, said, “We’re honored to have been selected by Eaton to join them at this pivotal stage of their additive journey. Our own direct experiences and learnings in mass scale production within the aerospace industry mean that we have an implicit understanding of what they’re trying to achieve.”

Nanda Kumar, president, Eaton’s Aerospace Group, added, “Additive capabilities provide new business opportunities and a strong competitive advantage. In five to ten years, we see a significant portion of our portfolio being manufactured through additive processes because of the investments we are making today.”

“Additive manufacturing is an exciting technology that offers many advantages. We look forward to leveraging GE Additive’s expertise and experience to accelerate our initiatives in this space.”

The Concept Laser systems are destined for Eaton’s Additive Manufacturing Center of Excellence at its Innovation Center in Southfield, Michigan, and the company’s R&D lab at a Global Innovation Center in Pune, India. Full installation is anticipate to be complete by August 2018.

“We were impressed with GE Additive’s consultants’ focus on strengthening our existing additive manufacturing program in a way that will accelerate our deployment,” said Mike York, director, Additive Manufacturing, Eaton’s Aerospace Group.

Metal powder production at AP&C extended with transfer from Avio Aero

When GE acquired additive manufacturing system developer Arcam in 2016, the deal included Montreal based AP&C.

AP&C uses a proprietary Advanced Plasma Atomization process to produce the spherical metal powder used in metal additive manufacturing. At Avio Aero’s facility in Cameri, Italy metal powder production is performed using a gas atomization method. The equipment currently installed in Italy will be transferred to the AP&C plant in Canada. Production is expected to commence by March 2019.

This move comes ahead of an expected increase in demand for titanium and nickel-alloy powder. While AP&C will continue to focus on material production and development, relocating the production facilities from Italy will also mean Avio Aero will dedicate itself to additively manufacturing aero engines components using Arcam EBM systems.

GE Additive also announced that AP&C is now the preferred supplier of TiAl for GE Aviation.

Alain Dupont, President & CEO, AP&C, said, “Without ongoing materials science research and innovation, additive will struggle to advance. So, while this relocation makes sense commercially, it is also a key element of our future materials development strategy. Having this complementary technology in the AP&C portfolio, opens up wider possibilities for us as a business and also for our customers, who continually to want to push boundaries.”

“The equipment moving to Canada means more volume and capabilities at our Cameri plant. And of course more 3D printing machines. In addition to focusing on additive processes we will also have the time and more space to train and equip our existing and new team members with future manufacturing skills,” said Giacomo Vessia, Cameri plant leader, Avio Aero.

For all the latest 3D printing news, subscribe to the Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Make your next additive manufacturing career move or hire new talent. Search and post Jobs on our free jobs service.

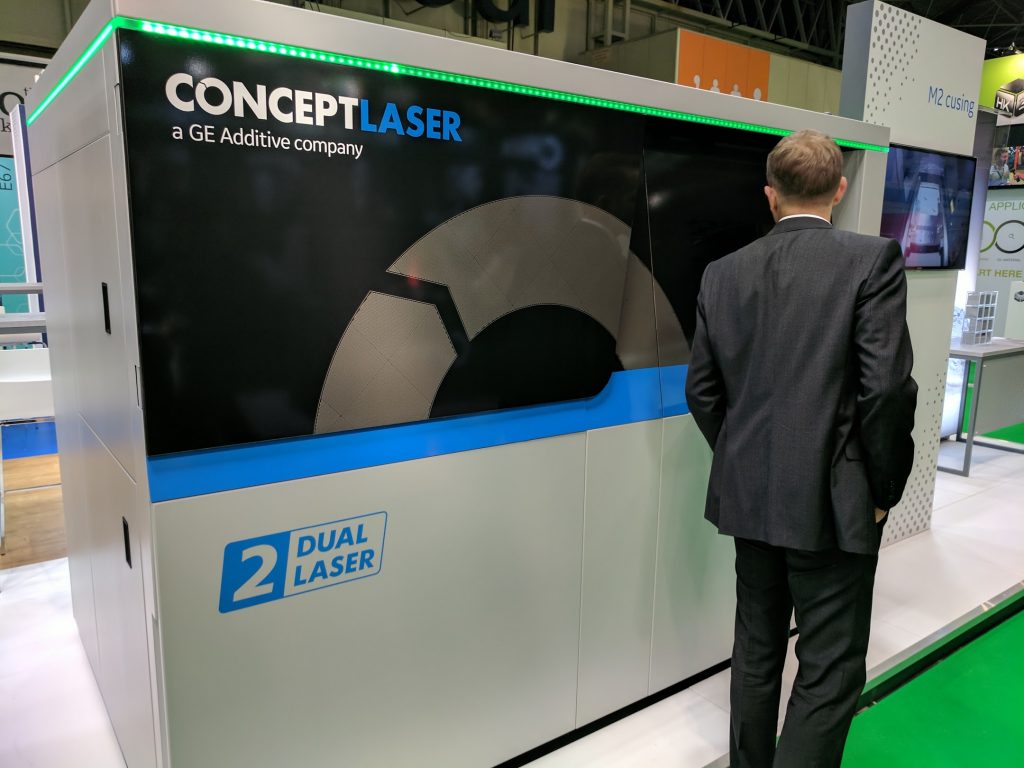

Featured image shows GE posters at formnext 2016. Photo by Michael Petch.

Leave A Comment