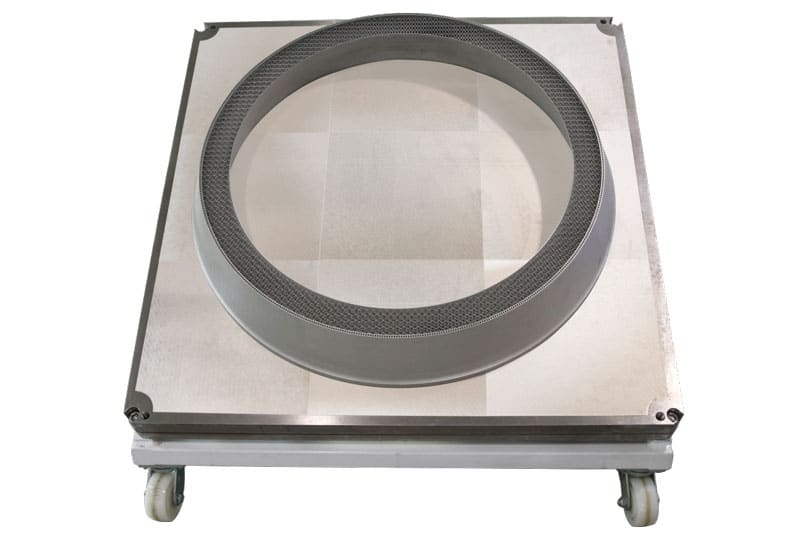

Eplus3D, a leading manufacturer of metal 3D printers, presented its newest large-format, multi-laser metal AM machine the EP-M1250. The new machine, which features a 1258 x 1258 x 1350 mm build envelope and nine laser systems, was built to increase the potential for multi-meter metallic part development and achieve the highest productivity and reliability.

The system can operate with various metal powders, including titanium, aluminum and nickel-based alloys, maraging steel, stainless steel, chrome cobalt alloys and other materials. It is suitable for the direct manufacturing of large-size, high-precision and high-performance parts in the aerospace, aviation, automotive and machinery industries.

To achieve homogeneous part properties all over the building platform, the gas flow has been optimized and redesigned to ensure the efficient removal of smoke and splashes as well as the achievement of uniform and consistent full-size printing. The build rate for the machine is up to 240 cm3/h, with a density of up to 99.9% and a <5% deviation in mechanical properties.

Manufacturing on Demand

As for software, the integrated process software offers the ability to divide the build model into different sections, for which process parameters can be individually applied.

The new EP-M1250 is intended to make the reliable production of high-quality large metallic parts viable on an industrial scale without requiring any tools, which paves the way to industrialized serial production and integration fully into the supply chain. As the production volume of aerospace systems increases and 3D printing is used by just about every company in the commercial space industry, the company expects significant demand.

Eplus3D is striving to provide tailored metal additive manufacturing solutions of large-scale parts to customers worldwide. A selection of high-quality and high-accuracy printed items by the EP-M1250 will be presented at Formnext 2022.

You might also like:

Visitech introduces LRS-8KA, the first 8K DLP UV projector: Visitech has developed its sixth-generation LED illumination solution, providing superior power output for maximum printing speed. The sophisticated driver design maintains constant power dosing throughout the operation. A complete, liquid-cooled thermal solution further provides the necessary heat management of critical components while mitigating the incursion of dust particles into the optical system. In addition, the compact, modular design is designed for easy replacement, simplifying maintenance routines in industrial settings.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: 3D Printing Media Network

Leave A Comment