Netherlands-based non-profit 3D Sierra Leone has been nominated for an award by the World Health Organization (WHO) in recognition of its work in 3D printing prosthetics for the West African nation’s amputees.

For nearly four years now, the group has used 3D printing alongside scanning gear provided by SHINING 3D to produce prosthetics for amputees in the country without access to postoperative care. In recognition of these efforts, the organization has been shortlisted for the WHO’s Special Prize on Health Innovation, which celebrates those projects that seek to benefit the wellbeing of people around the world.

3D Sierra Leone’s prosthetic project

As previously reported by 3D Printing Industry in 2020, Sierra Leone is a country whose healthcare system remains unable to deal with the wounds caused by traffic accidents or infections, thus it continues to see a large number of amputations. The nation’s lack of medical resources in this area are compounded by the fact that it’s still home to many amputees that survived its Civil War (1991-2002).

To make matters worse, due to the country’s lack of materials, staff and knowhow, many of these patients don’t have access to prosthetics, an issue that according to 3D Sierra Leone, can leave the afflicted feeling “jealous, insecure and depressed.”

In response to this problem, the group set up a pilot 3D lab at Masanga Hospital in Sierra Leone during 2018, at which it sought to test the feasibility of 3D printing low-cost prosthetics and other medical aids. Following the initial success of these trials, 3D Sierra Leone then began producing artificial limbs for people to use in practice, alongside students from the University of Twente and TU Delft.

Together, the project’s participants have devised a workflow, in which a patient’s stump can be scanned using a SHINING 3D EinScan Pro 2X Plus, over the course of around 20 minutes. This data can then be fed into Meshmixer software, where it’s turned into a 3D prosthetic model, which in turn, can be 3D printed from locally-sourced wood.

3D Sierra Leone says this standardized setup is more sustainable and affordable than normal prosthetic production methods, enabling it to be carried out independently by local communities. Since the project began, the potential of the organization’s approach has been borne out in a series of case studies that has seen various victims of disease and road accidents gain new artificial limbs.

In one such use case, a young boy was forced to have his right leg amputated at Masanga Hospital back in 2020, but after visiting 3D Sierra Leone, he was soon back on the move with a custom prosthetic. As of December last year, the patient had a bright red artificial limb (his favorite color), and the Dutch researchers behind the project had committed to creating a length-adjustable replacement for him soon.

In between helping a number of other amputees, the 3D Sierra Leone team has also made time to iterate upon their production process. During August 2021, the group revealed that it was developing a new design program which could help further simplify and automate its prosthetic manufacturing workflow, making it easier for locals to use themselves.

Moving forwards, in its most recent update, the group said that it intended to continue working in the country, with Pien de Graaf, a student at the University of Twente, expected to continue seeking new ways of optimizing its operations there.

Those interested in finding out more about 3D Sierra Leone’s case studies can access them via the ‘Project’ tab on the organization’s dedicated website.

Manufacturing on Demand

A WHO Special Prize nomination

In light of the humanitarian work achieved as part of 3D Sierra Leone’s project, it has now been shortlisted for the WHO’s Special Prize on Health Innovation 2022. The award seeks to recognize those that have developed social, digital or technological innovations which have a positive impact on the health of local communities.

3D Sierra Leone’s initiative has been nominated for the prize alongside eight others with similarly-good natured goals, based in both the Western and developing world. As part of the WHO-nominated 4,000 Meters Above Pain project, for example, a team are trying to help those recovering from depression, while a US shortlisted project is seeking to prevent girls from being forced into FGM in Tanzania.

Though the 3D Sierra Leone program was recognized by the Dutch Congress of Rehabilitation Medicine two years ago, its team would no doubt be delighted to win the WHO Special Prize for their work as well. The award’s winner will be decided by public vote, with people encouraged to post about the nominee they’d like to win under #Film4health, or comment under the project’s video on YouTube.

Voting is expected to close on May 10, 2022, with the winners set to be announced during the WHO’s Health for All Film Festival in mid-May.

Advancing prosthetic availability

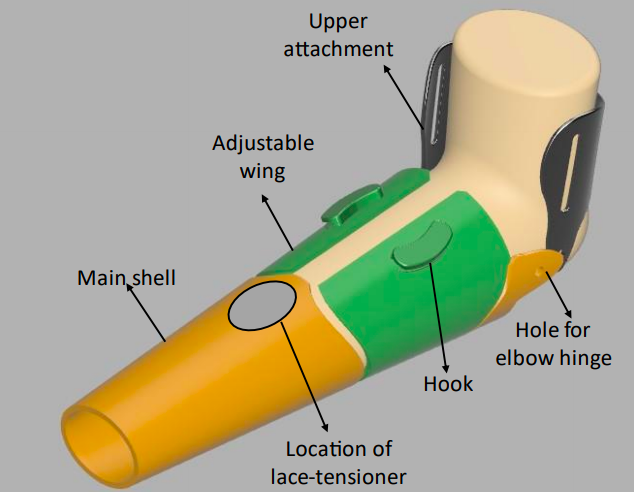

Since the 3D Sierra Leone team kicked off their project, various other groups of researchers have also used the innate manufacturing flexibility of 3D printing to drive the accessibility of prosthetic body parts. Mid-last year, another student at TU Delft managed to develop a low-cost upper-limb socket, which can be FDM 3D printed for as little as €30.

Prosthetic manufacturer Partial Hand Solutions (PHS), on the other hand, has begun using Formlabs’ Fuse 1 3D printer to create pediatric finger and elbow implants in-house. In doing so, the company says it’s now able to produce more durable nylon parts cost-effectively, while cutting their lead times down from two weeks to just a couple of days.

Away from the world of artificial limbs, the technology continues to be applied in the creation of many other artificial body parts too. In fact, a team of researchers in Korea have even managed to develop 3D printed testicles, designed to meet a growing demand for low-cost prosthetics in the country, and provide amputees with a timely confidence boost.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Paul Hanaphy

Leave A Comment