Black Buffalo 3D Corporation, a leading provider of large-scale 3D printers for construction, has named Dr. Kunal Kupwade-Patil as Chief Technology Officer (CTO). A leader in the 3D construction printing industry, Dr. Kupwade-Patil will head the development of sustainable and alternative cementitious materials and the development of nano-engineered cementitious materials. He comes from within the 3D printing industry where he has led multiple projects in advanced concrete technology as Head of Materials Science at ICON and was a Research Scientist in the Department of Civil and Environmental Engineering at Massachusetts Institute of Technology (MIT) for seven years.

“As we expand our global footprint, we’ll continue to lead by defining what’s possible with code-compliant materials, alternative cements, working towards carbon neutral ink, and green concrete,” said Michael Woods, CEO/COO of Black Buffalo 3D. “Kunal was instrumental in building this industry, and he brings a level of expertise that will continue to keep Black Buffalo 3D at the forefront of new materials development and more sustainable building practices.”

Throughout his career as a Research Scientist at MIT’s Department of Civil and Environmental Engineering, Dr. Kupwade-Patil oversaw student research and performed experiments at NIST, Argonne, and Oak Ridge National Laboratories. He represented MIT as a technical expert with industry leaders, including Saudi Aramco, Kuwait Foundation for the Advancement of Sciences (KFAS), NASA’s Kennedy Space Center, NASA’s Stennis Space Center, and Harvard University, to further research initiatives and partnerships. During his tenure there, he won grants from the US Department of Energy to fund research projects for the advanced characterization of sustainable construction materials.

Manufacturing on Demand

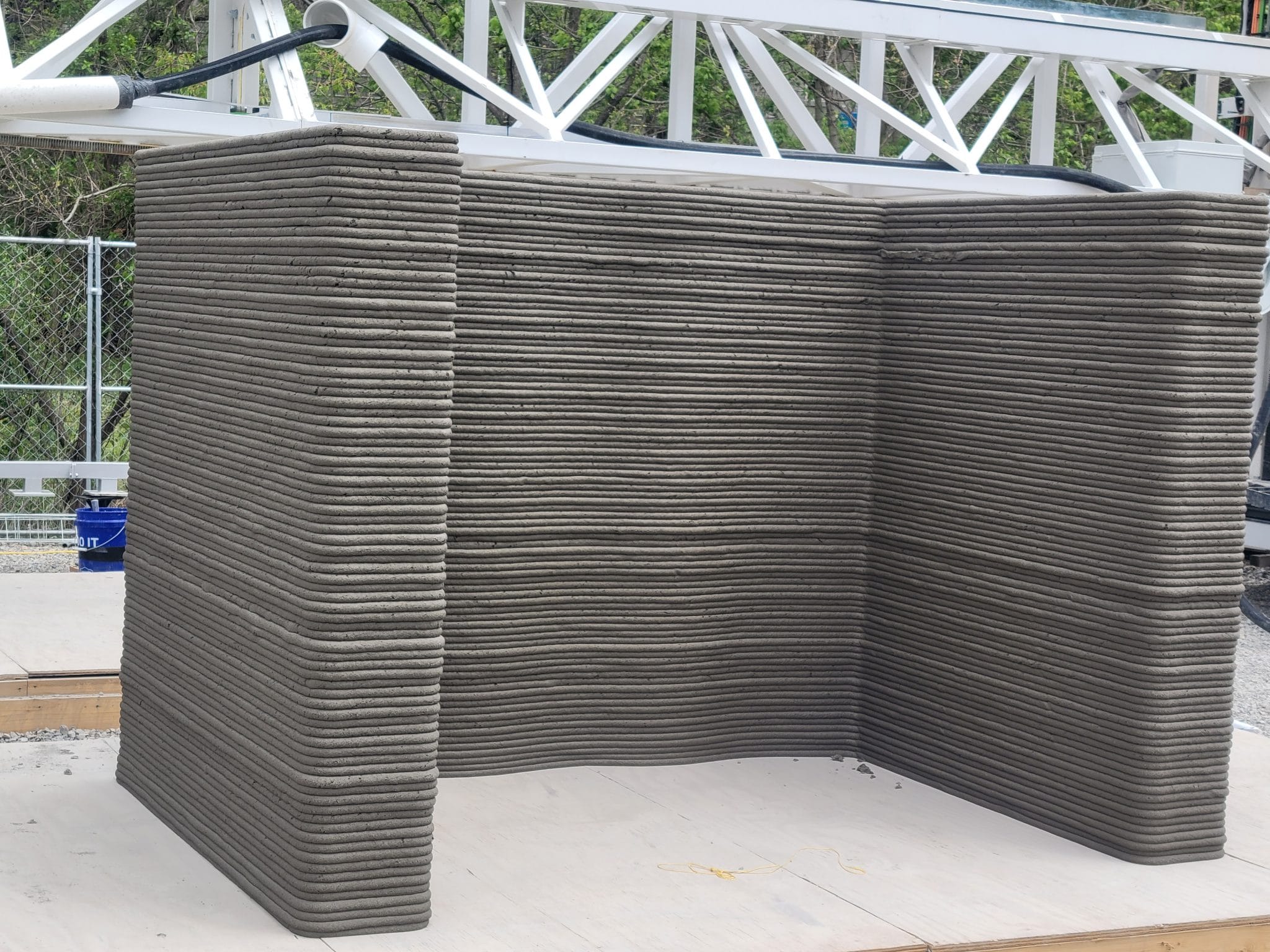

Within the 3D construction printing industry, Dr. Kupwade-Patil helped scale a startup, working with NASA and others to develop, build and deploy this new technology. He has over 70 publications including journal articles, conference presentations, NASA technical reports, and patents. His skill set will strengthen the ability of Black Buffalo 3D to innovate and further commercialize Black Buffalo 3D’s NEXCON printers while supporting the team’s development and testing of Black Buffalo 3D structural cement ink.

“Within my career, I have always sought to prove that in construction, strength and durability do not have to be sacrificed for sustainability,” stated Dr. Kupwade-Patil. “I am excited to join the Black Buffalo 3D team and develop the next wave of high-performance, ecologically sound concretes and technologies.”

Dr. Kupwade-Patil has intensively researched the use of natural materials in concrete to reduce emissions. He found that improved compressive strength can be obtained when rice husk ash partially replaces ordinary Portland cement, and he plans to develop technologies at Black Buffalo 3D that will include agricultural biomass like industrial hemp in structural concrete admixtures. His work extends to the potential of using other natural materials like volcanic ash to reduce emissions and make concrete even more durable.

With over 18 years of experience in cement and concrete technology, Dr. Kupwade-Patil will apply his knowledge to the continuous improvement of 3D printing ‘ink’ admixtures and additional pilot projects, as well as continue to research innovative applications for construction-related additive manufacturing.

You might also like:

100kgs of Titanium powder ordered from PyroGenesis: Aubert & Duval, a subsidiary of Eramet group, is a world leader in industrializing high-performance steel, superalloy, aluminum, and titanium alloys. More specifically, they are a supplier of metal powders for additive manufacturing, serving the aerospace, energy, transport, medical, defense, automotive, and other large-scale, markets.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment