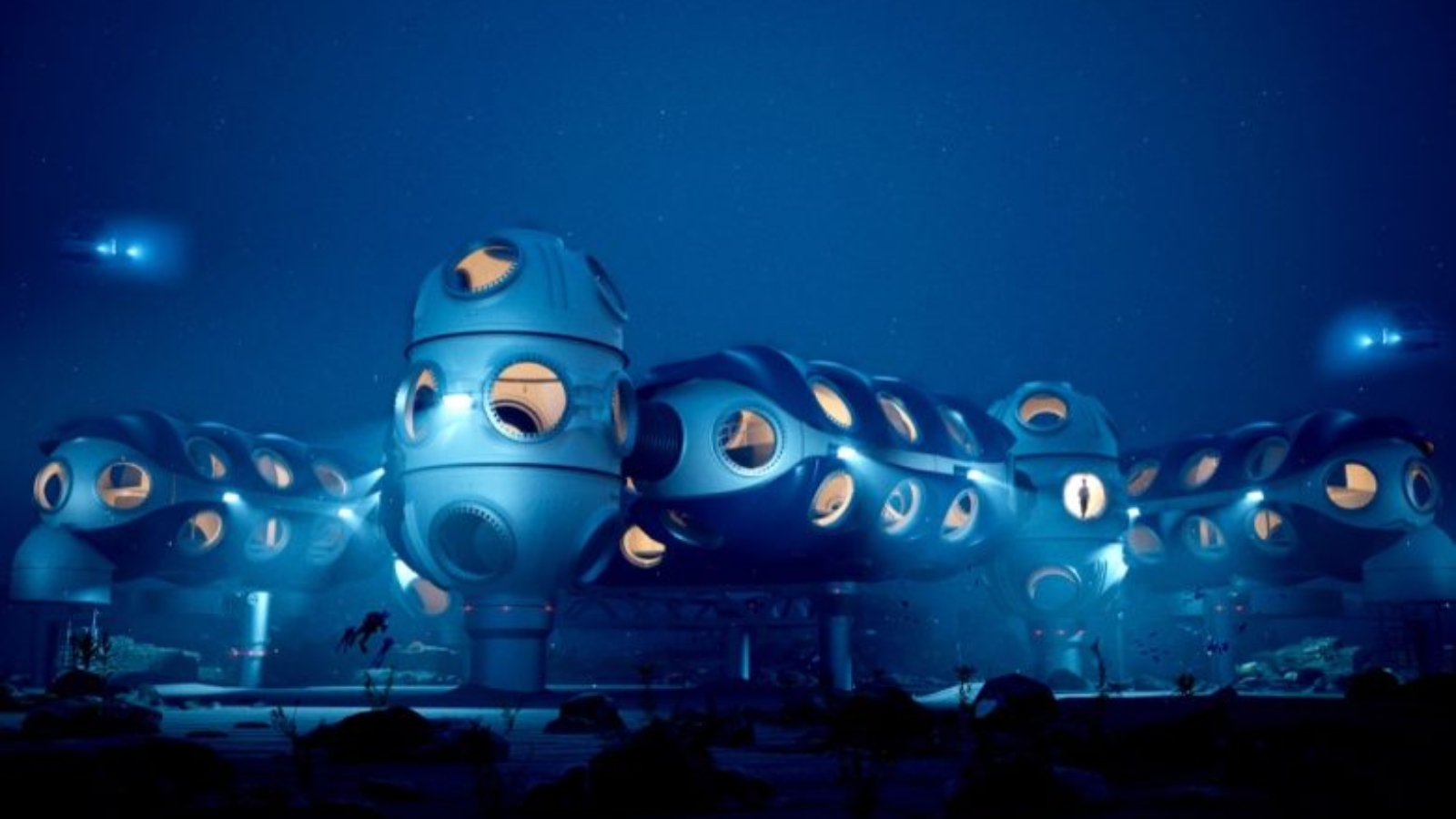

DEEP is emerging from stealth with the project of a subsea station that will revolutionize access to and understanding of our planet’s oceans. Scalable, modular, and autonomous, the DEEP Sentinel system will be built using primarily WAAM metal 3D printing technology. It has been designed for deployments up to 200m below the surface. This radically opens up access to the world’s continental shelves and the entirety of the Epipelagic Zone (sunlight zone), home to over 90% of marine life. To study, understand, and preserve Earth’s most important biome we must first be able to access it, and DEEP exists to develop technology for exactly that purpose.

Steve Etherton, President, EMEA of DEEP, said: “We need to preserve the oceans. To do that we need to understand them. The oceans sit at the center of many of the generational challenges the world is facing, and they also offer opportunities we have not even begun to comprehend. They are the source of at least every other breath we take. They influence the weather. They influence the climate. They influence us. Yet, this life-sustaining ecosystem remains surprisingly unknown. Through our innovative technology, DEEP will enable scientists to operate at depth for extended periods of time and we hope, in some small way, will contribute to our understanding of this life-giving environment”.

The DEEP System comprises Sentinel the underwater habitat, and a revolutionary range of submersibles, dive and scientific research equipment. All backed up by technical and human performance training and qualification programs (DEEP Institute), and a unique underwater R&D test and operations facility (DEEP Campus).

World’s first 3D printed pressure hulls for humans

The Sentinel will be globally classed by DNV, the world’s leading classification society for underwater technology and will allow scientists to live underwater at depths of up to 200 metres for up to 28 days at a time. This will give extended access to most of the world’s continental shelves and importantly being able to descend to 200 meters allows access to the entirety of the Epipelagic, or “sunlight”, zone. The lower limit of the Epipelagic zone is the deepest point at which sunlight penetrates into the ocean and it’s estimated that 90% of marine life is found in this zone. Being able to comprehensively explore the full extent of this part of the ocean rather than just performing incursions from the surface, will represent a step-change in the way scientists can observe, monitor, and understand the oceans.

Following two years of intensive and pioneering research into innovative manufacturing processes and materials science, DEEP is at the advanced stage of technical design and has commenced production. The DEEP system offers a radically more effective way to live and operate underwater than has existed before. Previously, underwater facilities have been temporary and fixed-location. DEEP’s habitat is modular, scalable, autonomous, recoverable, re-configurable and re-deployable.

“We have selected Wire Arc Additive Manufacturing (WAAM) as the technology used to produce Sentinel hulls, meaning we will be creating some of the largest 3D printed objects ever made and the first Additively Manufactured pressure hulls classed for human occupancy,” said Sam Tiller Delivery Lead – Advanced Manufacturing at DEEP via his LinkedIn profile. “The primary activity of the program is the technological development of multi-robot arm collaborative WAAM systems for this application. Development is well underway – DEEP has made a significant investment in WAAM hardware and we have an outstanding team and external partnerships with companies at the cutting edge of the field.”

Whether the project succeeds or not, whether you may think that it’s too ambitious, one thing that is now extremely clear is that no advanced project can exist that does not take into consideration the extensive use of additive manufacturing. Relativity Space, the Stellarator fusion reactor, just about every rocket in development… Many of these use WAAM for the largest structures, but PBF is increasingly adopted as well.

DEEP into DED

DEEP Advanced Manufacturing offers capability and expertise in large-format metal Additive Manufacturing, rapid prototyping, materials testing, and other areas. The company has invested primarily in technology within the Direct Energy Deposition (DED) family of Additive Manufacturing processes and is undergoing a technology development program to advance this capability to the point of printing pressure hulls for the Sentinel Habitat.

WAAM was selected by DEEP as the preferred manufacturing method for Sentinel pressure hulls due to its high deposition rates, scalability, and support for various metal feedstock materials. The company has invested in a significant number of WAAM systems comprising Valk Welding torches, Panasonic robot arms, and RAMLAB control and monitor hardware and software. These can be used individually to produce parts across a wide range of materials and geometries. However, in order to produce the large segments comprising a Sentinel pressure hull, DEEP is undergoing an ambitious technology development program with RAMLAB to develop a multi-arm collaborative WAAM. This will see six individual WAAM systems arranged in a hexagonal configuration, working synchronously to produce 30T+ hull segments at world-leading deposition rates.

Manufacturing on Demand

The company has collaborated closely with Valk Welding to select and optimize a Wire Arc Additive Manufacturing (WAAM) feedstock material for use in the Sentinel hull. This material has been carefully selected to ensure uniform weldability, material properties, and quality and is currently undergoing DNV Type Approval to affirm its suitability for subsea applications.

In parallel, DEEP is working closely with DNV to achieve approval of the WAAM process for safety-critical subsea applications. Collaboration with other industry leaders has accelerated creative problem-solving and breakthrough technological development, and DEEP is on track to deliver the first-ever Additively Manufactured pressure vessel certified for human occupancy.

Laser Metal Deposition (LMD) is another technology within the Direct Energy Deposition branch of Additive Manufacturing. Unlike WAAM, a laser is used to melt and deposit material. DEEP has invested in a Meltio Engine LMD system which is integrated on a robot arm and allows the production of small to medium metal parts in a range of materials. Complex geometries are made possible by a 2-axis turntable and industry-leading path planning software from AI Build.

DEEP is currently utilizing its Meltio system for Advanced Manufacturing process development, rapid prototyping, and non-safety critical parts for the Sentinel and Subs products.

More 3D printing under the sea

DEEP is also developing capability in rapid prototyping including large-format polymer thermoplastic material extrusion 3D printing, materials testing, generative design, and more.

Rapid prototyping offers DEEP and its partners a range of benefits, including accelerated time to market and cost reduction through early issue identification. It fosters innovation, facilitates effective communication, and promotes user-centric design by gathering early feedback. This approach mitigates risks, supports iterative improvement, and confers a competitive advantage while fostering design flexibility and enhancing cross-functional collaboration.

DEEP operates three FFF 3D printers: an Ultimaker S5, BCN3D Epsilon W27, and Builder Extreme Pro. These offer a comprehensive Rapid Prototyping capability and are containerized for easy transport and deployment anywhere in the world.

Mike Shackleford, President, of Global Services of DEEP said: “We have made significant investments in advanced manufacturing processes, and will build one of the world’s leading fabrication facilities with innovative production methods which will reduce waste, enhance energy efficiency, offer bespoke design and shorten manufacturing timelines. DEEP’s facilities already house our prototyping and pre-production capabilities as well as advanced material testing infrastructure not found elsewhere in the UK, and this is just the beginning”.

Investment in DEEP Campus will transform the old National Dive & Activity Centre, into a world-leading 600-meter-long, 100-meter wide and 80-meter-deep controlled water facility for training5, testing, and research. DEEP Campus will become a core part of the regional ecosystem, hosting essential development exercises for DEEP as well as regional, national and international partners.

You might also like:

Mighty Buildings raises $52 million in funding: Existing investor Khosla Ventures and new investor KB-Badgers, a South Korean fund focused on advanced manufacturing, automation, and sustainability, were among a total of almost 20 investors in the round. The new investors contributed more than half of the funds raised.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment