The Danish Technological Institute (DTI), an independent not-for-profit R&D institution headquartered in Taastrup, is to open a new 88 million krone ($14.5 million) 3D printing center.

The new “AM-LINE Center” (named after its “AM-Line 4.0” parent project) will feature manufacturing facilities, training resources for SMEs, and professional advice on investing in 3D printing. It is set to open at the site of the DTI’s existing Aarhus facility in spring 2018.

Boosting Danish business with 3D printing

A report published by the DTI in 2016 showed that only 4% of Danish SMEs were making use of 3D printing technologies. DTI product development lead Claus Erichsen Kudsk noted at the time that neighbouring nations had a more competitive edge because of their investment in 3D printing.

“Faster and easier development of prototypes is especially a prerequisite for continuing to maintain competitive jobs,” Kudsk said, “but also to maintain a high level of product innovation and to have opportunities for a faster launch of new products.”

The DTI, which has had 3D printing facilities since 1989 and has recently been involved in 3D printing concrete structures and metal, sought to increase the uptake of 3D printing in Denmark when it announced the new centre in April 2017.

“Small and medium-sized businesses are particularly missing out on the competitive advantages of 3D printing,” DTI section leader Jeppe Skinnerup Byskov noted. “The technology is so fashionable that even small businesses can benefit greatly from the big potential of 3D printing.”

Production at the AM-Line Center

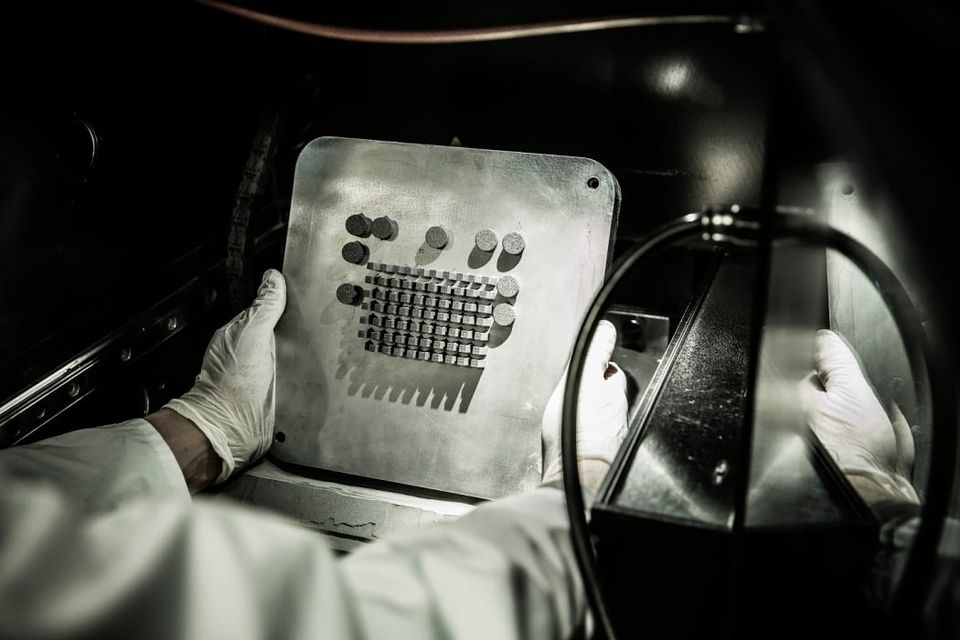

Now constructed, the AM-Line Centre will offer SMEs access to four metal 3D printers and a variety of plastic 3D printers. The facility will also offer post-processing equipment, surface treatment and quality assurance with CT scanning.

“The center will be a full production facility where companies can develop and print products that they can subsequently implement directly in their own production lines,” said Byskov.

Originally, the facility was to produce more than 3,000 3D printed components and to train more than 500 engineers, designers and directors in technology, but revised targets are yet to be announced by the DTI.

Unlocking long-term business progress at the AM-Line Center

Training and education at the facility will be undertaken by 3D printing companies Danfoss (which was also a significant investor in the project) and the Manufacturing Academy of Denmark (MADE). The other DTI partners on the AM-Line 4.0 project, Adimant, Scada Minds, the Technical University of Denmark (DTU), Niras, TWI and Grundfos, will be responsible for research, production, optimization and quality assurance. Byskov adds,

“For companies that are new in 3D printing, we will be able to offer a wide range of custom upgrading courses from shorter inspirational workshops for long-term business progress,”

“In addition, for those companies that are far advanced in the use of 3D printing, we will be available and guided for example, in purchasing their own 3D printers or subcontractors to scale up their production.”

The facility has been welcomed by Danish chambers of commerce, with Dansk Industri (DI) Director Kent Damsgaard stating that “It will give small businesses a good and obvious chance to get started with the new opportunities offered by 3D printers.”

Nominations for the second annual Industry Awards are now open. Make your selections now.

For more stories on 3D printing and SMEs, subscribe to our free Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows 3D printing metal can add complex geometries and optimize parts for end use. The facility will also have post-production equipment. Photo via DTI.

Leave A Comment