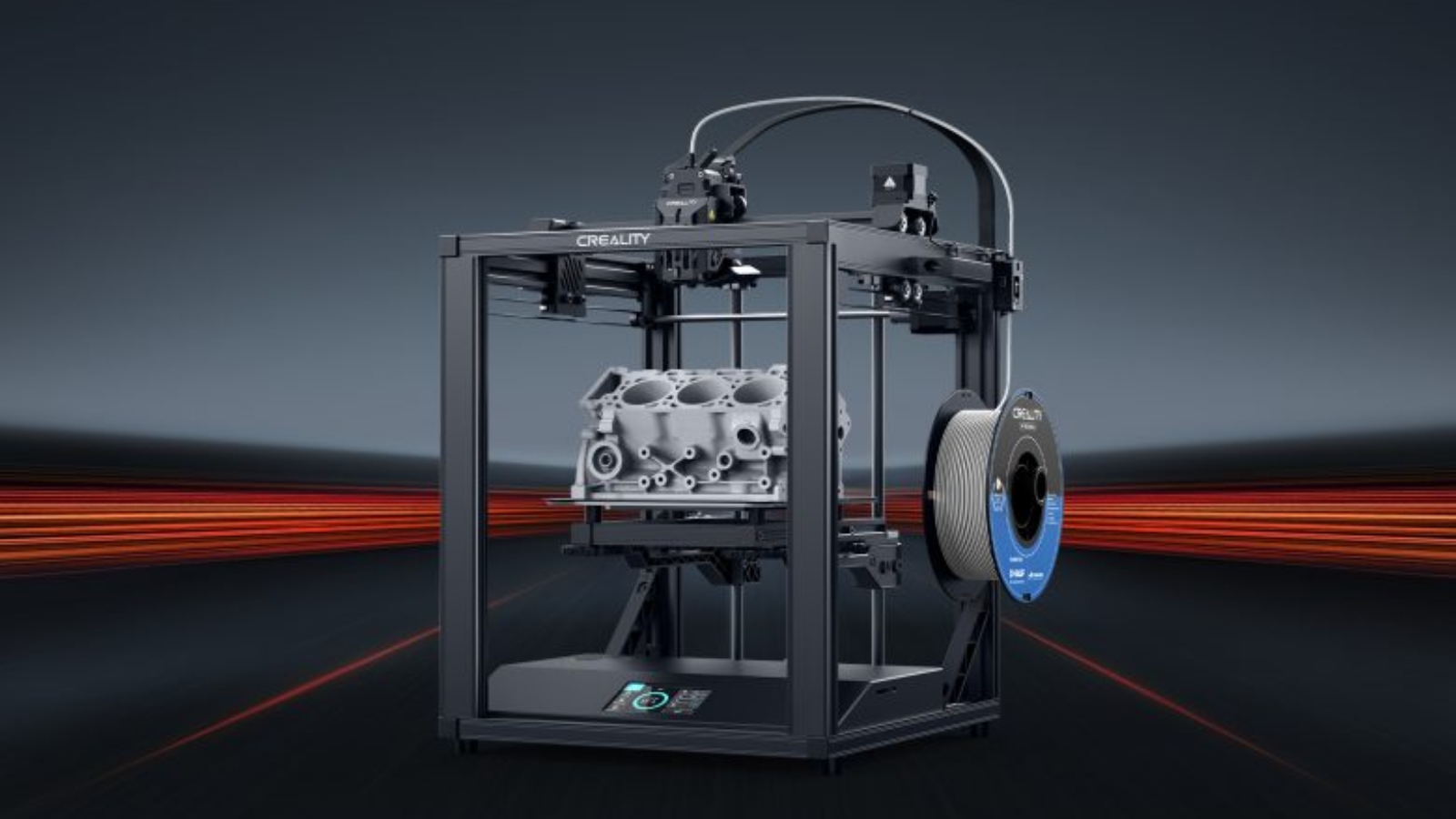

Creality has officially launched the Ender-5 S1, the latest printer in the company’s Ender series of FDM printers. According to Creality, the Ender-5 S1 has been designed not just to be another one of the printers in the series, but “a flagship that integrates and reinvents the essence of this popular series”. The upgraded motion system, which enables an acceleration speed of 2,000mm/s², and a printing speed of up to 250mm/s printing speed, is one of the ways the company is making this happen.

“As a user-centric company, Creality strives to bring affordable 3D printers, combining market-leading technologies and stable, high-level performance, to 3D printing beginners and professionals around the world,” said Ao Danjun, CEO of Creality. “As the latest addition to our ever-popular Ender series, the Ender-5 S1 aims to be a leader in the desktop-grade 3D printer market and empowers users to turn their dreams into realities.

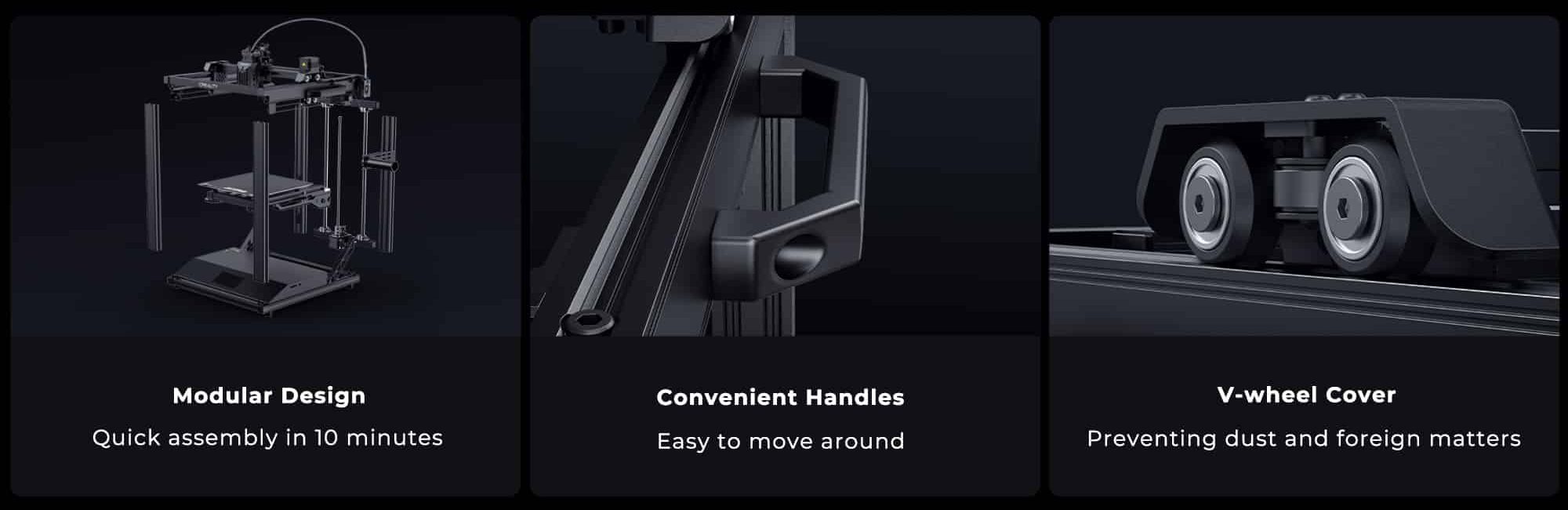

Following the success of its Ender-5 series predecessors, the Ender-5 S1 also comes with an all-metal cube frame design featuring the classic Cartesian structure. It can be assembled in only 10 minutes, while the stability is further enhanced by two Z-axis 12mm linear shafts, and two profile gussets. Unlike single gantry printers, each X/Y/Z axis of the Ender-5 S1 is driven by a powerful, high-precision stepper motor. A steel transmission shaft has been equipped to connect and sync the two Y-axis belts – significantly increasing durability and precision, without compromising on printing speed.

Test results from the Creality Lab show that printing a 3DBenchy takes only 54 minutes at the maximum speed. The Ender-5 S1 also achieved a 100% success rate for 1,000 hours of printing with a 0.2mm layer height at 250mm/s – proving reliability.

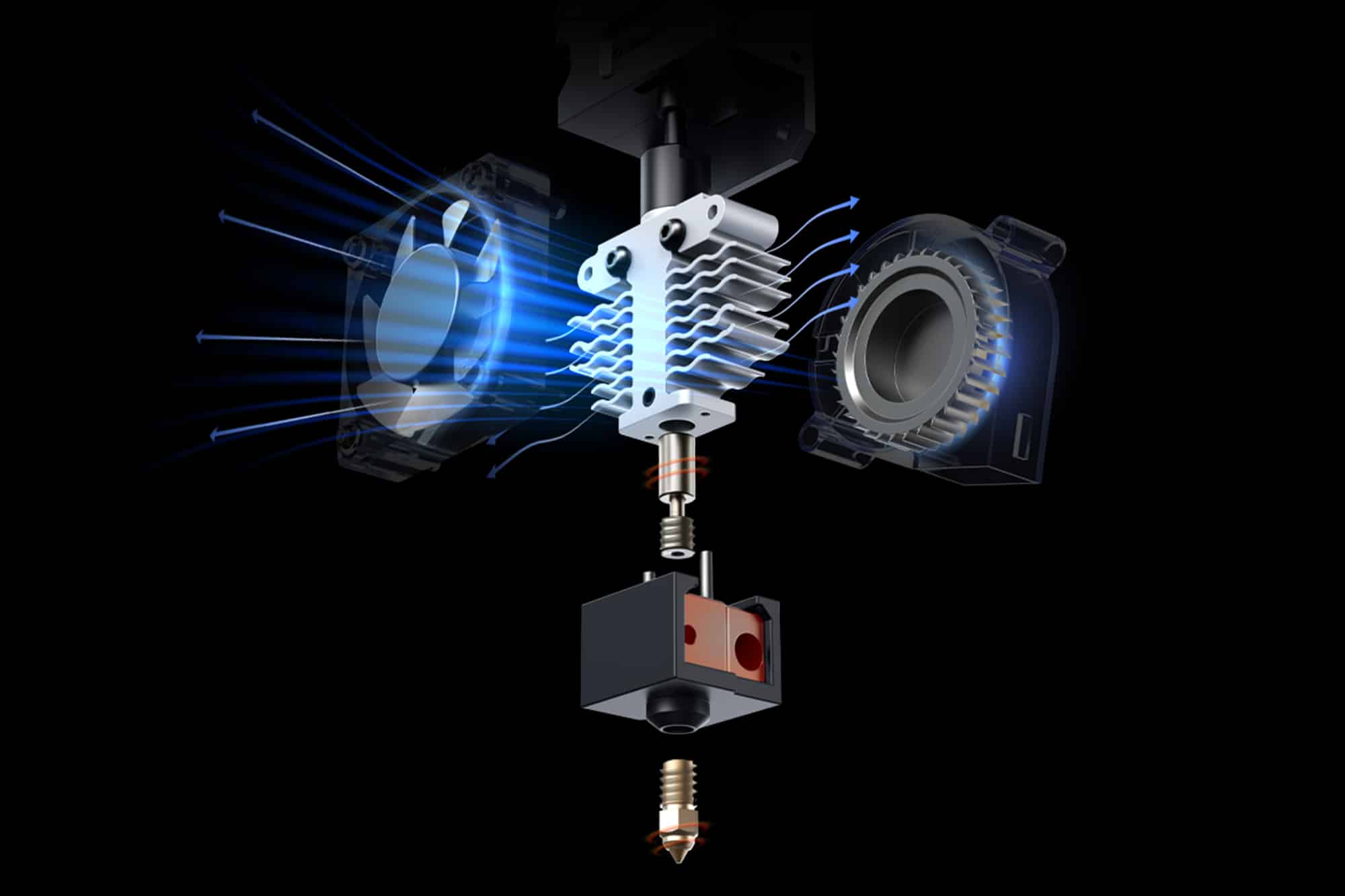

The Ender-5 S1 is the first in the Ender-5 series to feature high-temperature printing – made possible thanks to Creality’s self-developed all-metal ‘Sprite’ direct extruder. The ‘Sprite’ features dual gears with a 1:3.5 gear ratio, delivering a powerful and uniform 80N extrusion force, and is particularly capable when printing with flexible filaments like TPU.

When the filament is first fed in, it goes through the low thermal conductivity Titanium alloy heatbreak, to sufficiently prevent heat creep. The corrugated heatsink and silent axial flow fan then ensure that the filament is cooled before reaching the hot zone.

The melting chamber has also been significantly upgraded. The 50mm³ melting chamber of the Ender-5 S1, surrounded by a large 4,000mm³ heater block, is capable of fully melting the filament for smooth feeding. The tests from the Creality Lab prove that the Ender-5 S1 is capable of 1,000 hours of clog-free feeding.

Manufacturing on Demand

Apart from regular filaments, like TPU, the Ender-5 S1 opens the playing field to a whole range of heat-resistant engineering plastic filaments, including ABS, PC, ASA, and HIPS. For users pursuing a better high-temperature printing experience, an acrylic enclosure, specifically designed for the Ender-5 S1, is available as an optional extra – for keeping the heat of the chamber.

In addition to the upgraded ‘Sprit’ extruder, the Ender-5 S1 is equipped with extra cooling technology. A pair of ‘Urus’ air ducts, mounted alongside the nozzle, channels the strong wind generated by a large 5015 fan to directly cool the freshly printed section. The deposited hot material then hardens and bonds immediately – avoiding drooping or warping caused by overheating. The additional cooling method improves the print quality of overhangs, bridges, and other detailed objects. With the magnetic PC spring steel sheet, users can also remove the model easily, with a slight bend, after printing.

Creality’s CR Touch 16-point auto-leveling system comes preinstalled on the Ender-5 S1, offering hassle-free bed-leveling. For the perfect first layer, Creality recommends that its users adjust the print bed – first by the 0.01mm Z-axis offset, and then the five-point auxiliary leveling, before going through the CR Touch leveling method.

This can all be done through the responsive 4.3-inch touchscreen, which features a wide viewing angle and a simplified UI. Temperature PID tuning function has also been added for accurate and steady temperature control.

For the first time, a secure aviation connector has been applied in the Ender series, which debuts on the Ender-5 S1. The 350W power adapter is also encased in the printer’s base – for a safer user experience. Creality has also removed all loose cables – which are now coated with the nylon wire harness sleeve for safety and tidiness.

In addition to printing by inserting an SD card, and connecting your PC via a USB cable, remote control operating, via WiFi, and time-lapse filming are also made possible by connecting the optional Creality WiFi Box 2.0 + Camera Kit, which can be purchased separately. With the connection of the Creality WiFi Box 2.0, users can remotely control their printers via the Creality Cloud app on their phones.

The Ender-5 S1 is now available at Creality’s Official Store, for $559. The first 100 purchasers will be given an early-bird price of $469, and the first 50 will receive a complimentary 1kg roll of random-color Creality CR series filament.

You might also like:

The year of the binder: Segment pioneer ExOne introduced its first metal binder jetting system nearly two decades ago, after licensing the original patent from MIT in 1996. However, only recently has the company introduced new systems tailored for higher productivity. ExOne did so as a response to several other large players announcing plans to enter the market for metal binder jetting. In particular, working with metal binder jetting technology inventor Eli Sachs, Desktop Metal was founded in 2015 by serial entrepreneur Ric Fulop, and introduced the concept of a high-productivity metal binder jetting system. Fulop’s intuition was that by optimizing and automating the post-processing phase (including eliminating the need for metallic supports during the build phase), metal binder jetting workflows could deliver significantly higher productivity and thus lower per part cost than the more established metal powder bed fusion technologies.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment