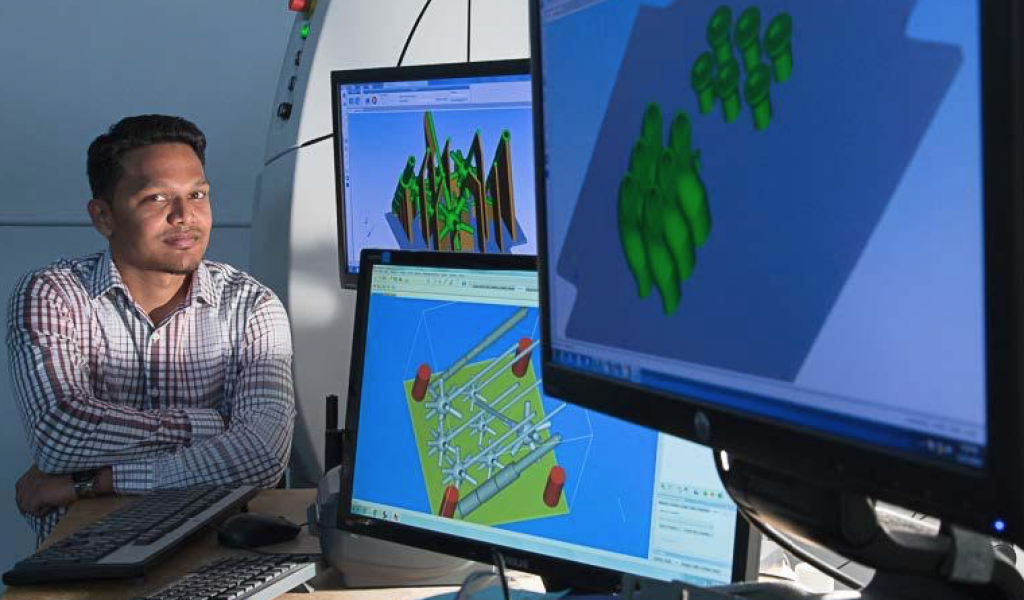

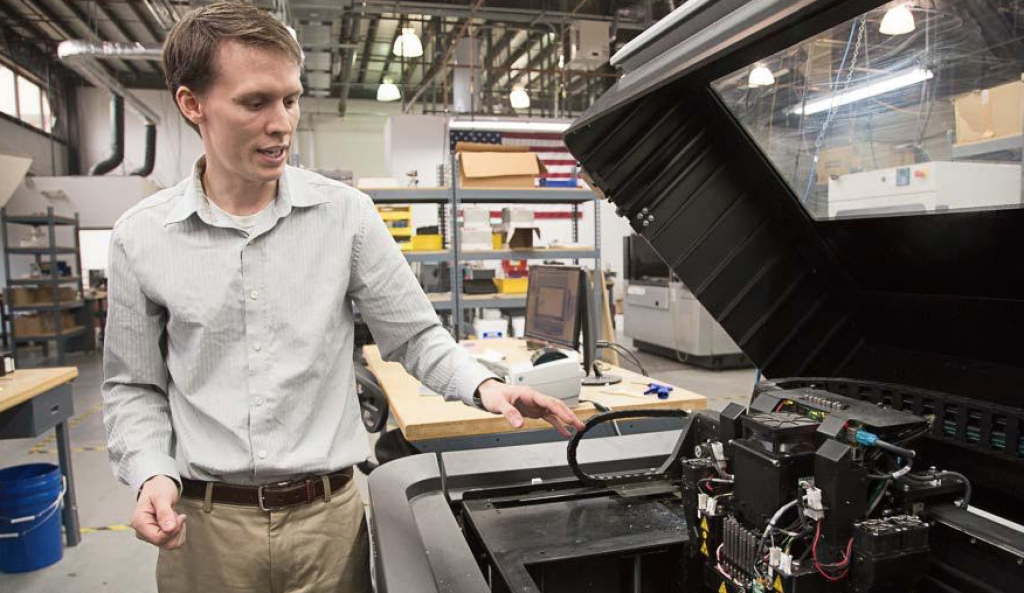

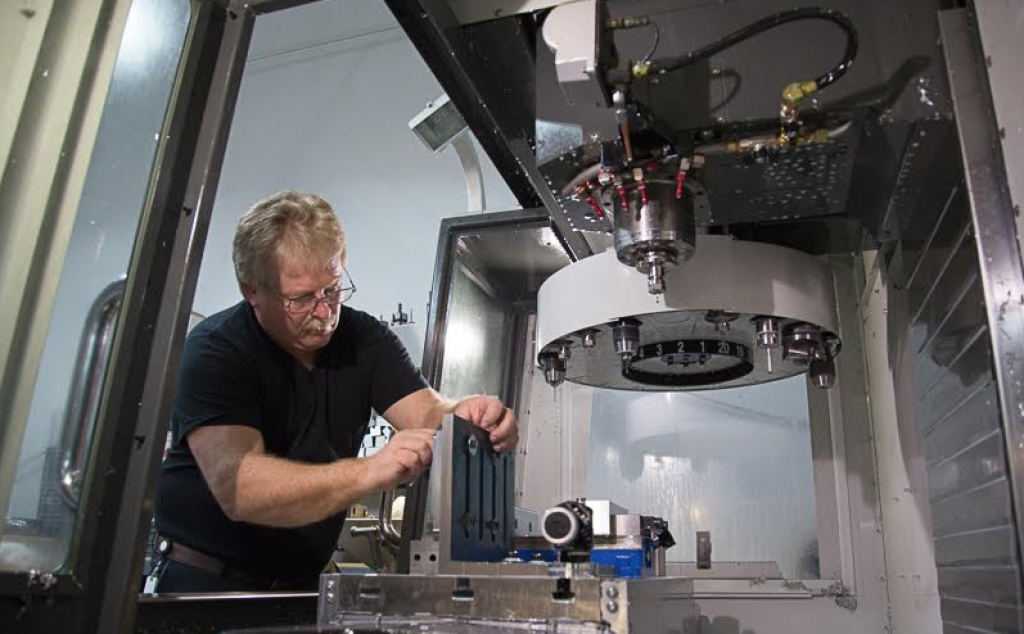

Usually, when American businessman Randy Altschuler touches upon a business model, it turns to gold. The esteemed CEO has started and sold successful companies such as OfficeTiger (now acquired by RR Donnelley) and CloudBlue, both of which were acquired for quite the handsome sum. His latest venture, Xometry, is primarily centered around 3D printing technology, and plans to become an innovator in the rising customizable and on-demand additive manufacturing industry. Xometry, which was first launched back in 2013, focuses on providing two 3D printing-centered services. The first is a software platform which works to streamline manufacturing orders, offering a clean and informative all-in-one ordering dashboard comparable to Amazon. The second facet of their company is a high-tech manufacturing facility, which includes CNC machining, DMLS, metal binder jetting, and other processes.

The company currently has 50 employees on staff, but with a newfound focus on software development and marketing, they plan to double that amount by the end of the year. Already connected with established customers such as NASA, General Electric, Raytheon, and Toyota, Xometry has already seen a measure of success. In their brief existence, they’ve already raised $16 million from private investors, including $8.8 million in a series round led by Highland Capital Partners. Xometry has about 16,000 customers thus far, and is certainly tapping into a critical need in the manufacturing market. Xometry is especially ideal for 3D printing small batch manufacturing and limited product releases, providing a service that Altschuler describes as an “online interface that acts as an easy-to-use custom manufacturing hub.”

“Whether you are a Fortune 100 company or a startup, you receive instant pricing and expert recommendations just by uploading a 3D-CAD file. It’s the same process whether you need a CNC Machining solution, 3D-printed part or Urethane casting,” Altschuler said. “In the past, in order to build a custom part, it took considerable time to figure out the manufacturability and pricing. We simplify the process and help ensure you get the parts you need at a low cost.”

When customers enter in their CAD file into the Xometry system, the software will offer suggestions based on what is important to the consumer, such as price-point, material specifications, or quick turnaround. The ultimate goal for the Xometry team is to help push the US manufacturing industry through the inevitable digital transformation happening around the world. The team compares this transformation to the rise of online retailing that took place over the last decade, and hopes to keep scaling out their software platform and one day become the industry standard for additive manufacturing.

“The more innovative the U.S. manufacturing industry can be, the more we can meet the needs of American businesses and help them drive their own innovation in their own categories. We see Manufacturing as a Service as a key growth opportunity for the industry,” Altschuler concluded.

Leave A Comment