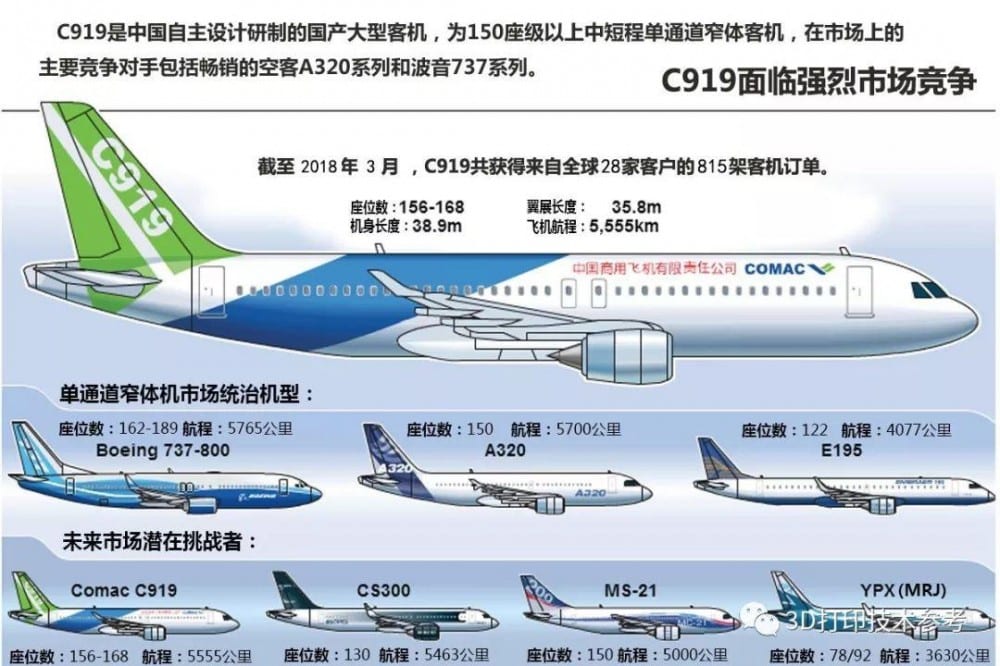

Introduction: The C919 domestic 101 passenger aircraft made its first flight after completing the transfer to Xi’an Yanliang Airport in November 2017, and then completed about 60 test flights. It is currently in the stage of conducting a charter expansion R & D test flight.

On December 28, 2018, 103 C919 large passenger aircraft successfully took off on the fourth runway of Shanghai Pudong International Airport, stayed in the air for 1 hour and 38 minutes, and completed 21 test points, which coincided with the tenth anniversary of the establishment of COMAC and Chinese The best gift is presented.

According to COMAC, there are still three test flight aircraft to be assembled and assembled this year, and all six test flight aircraft are planned to be put into test flight certification. The internal structure of the 103 C919 large passenger aircraft has been adjusted based on the results of the previous flight test and will apply for a type certificate (TC) from the Civil Aviation Administration of China. This marks another breakthrough in the development of domestic large passenger aircraft.

By the end of 2018, the C919 large passenger aircraft had received 815 orders from 28 customers. From drawings to landing, from passing various tests to many successful test flights, when the manufacturing and design capabilities of large domestic aircraft have been verified, again and again, the C919 large aircraft that has worn a sword for ten years, I believe that the sword will be pointed to the sky shortly, Open a future contract with the international market!

“Made in China” is in the limelight

A C919 large passenger aircraft has 724 cables, 2328 conduits, and a pipeline with a total length of nearly 80 kilometers. The total number of parts is 2.5 million. It is not easy to combine so many parts. However, although the C919 large passenger aircraft is completely designed by China and overcomes the problem of system integration, there is a voice of doubt that never stops. The C919 large passenger aircraft uses the LEAP-1C engine purchased from the United States. Is a large aircraft without a “heart” still considered an authentic “national product”?

The aero-engine can be called the “pearl of the crown” in the modern industry. It directly affects the performance, reliability, and economy of the aircraft. For a long time, aviation engines have always been the weakness of China’s large aircraft industry. China’s aviation development market has always been occupied by foreign companies, and it has to squander hundreds of billions of dividends.

Gan Xiaohua, the academician of the Chinese Academy of Engineering, said that the design and manufacture of aircraft generally take 15-20 years, and the engine takes 20-25 years; 20-30 companies can make aircraft in the world, but only 3-5 can do engines.

Although there is no small gap in the level of research and development, domestic aero engines are an inevitable choice. At the end of 2017, the assembly of the CJ-1000AX, the first domestically produced large passenger aircraft engine CJ-1000A, was completed, marking the establishment of China’s first civilian large bypass ratio turbofan engine verification platform. In mid-2018, with a roar, the C919 large passenger aircraft aero-engine CJ-1000AX verification machine was successfully ignited, and the core engine speed reached a maximum of 6,600 rpm, marking that China’s large passenger aircraft aero-engine has finally passed the most difficult step. Follow-up will further carry out the preliminary test of the preliminary performance of the whole engine. If it can pass the rigorous test, the verification machine will become a real product. The C919 large passenger aircraft and large transport aircraft Yun-20, and the amphibious aircraft AG600 will have one The real “Chinese heart”.

At the beginning of the project, the localization rate target of 10% was set. Today, the localization rate of the C919 large passenger aircraft is nearly 60%. The “final realization of all localization” is the goal of the big aircraft.

Airworthiness certification

Airworthiness and market are always the two keywords of civil aviation products. Even with a domestic engine, there is a problem that cannot be circumvented. Some people say that the biggest bottleneck of the C919 is not the engine, but a thin airworthiness certificate.

3D printed 3.07m high C919 central flange

Although the civil aviation departments of various countries have different standards, the airworthiness certificate of the United States and Europe has almost become internationally used because of the early development of the US and European civil aircraft and the relatively mature technology.

“This is like an online game. After internal testing by developers, a small-scale internal test will be conducted, and then a public test will be conducted before finally going online.” An aviation industry person said. Before obtaining the approval issued by the Civil Aviation Administration of China, the multiple test flights of the C919 test aircraft were in the early stage of R & D test flight, that is, “internal testing”. The good news that 103 aircraft are about to be used to apply for model certification indicates that the C919 large passenger aircraft is about to undergo official tests by the Civil Aviation Administration of China, complete more than 1,000 compliance verification tests, and enter the “open beta” runway, becoming the first “real” C919 “.

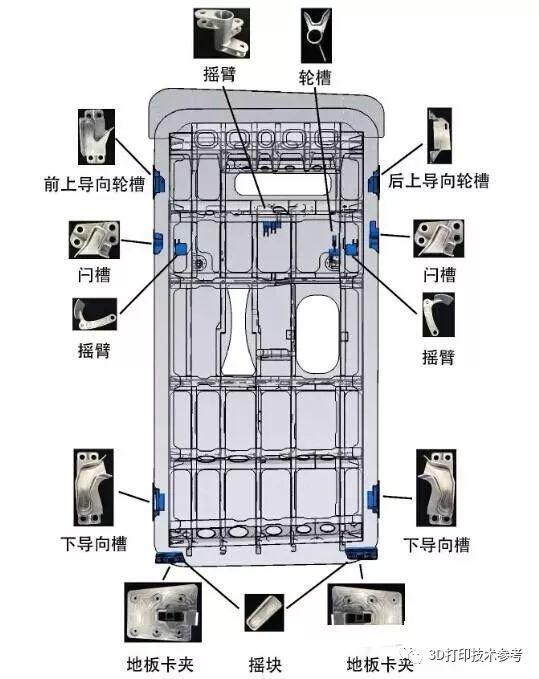

3D printed layout of titanium alloy parts of C919 aircraft boarding door

Thanks to the airworthiness experience of ARJ21 civil aircraft many years ago, the certification process of C919 large passenger aircraft became more convenient. It took more than three years for the ARJ21 to fly from the first flight to obtain approval, and the entire airworthiness certification took six years. With C919’s turn, the time is expected to be greatly shortened. Zhang Yingchun, the leader of the C919 model qualification review team, said: “It is too optimistic to obtain evidence in 3 years, but it is too long to obtain evidence in 5 years.” In addition to the accelerated test flight process, the total assembly speed of the C919 large passenger aircraft will be further improved. In addition to the 103 aircraft that require a lot of research and development and test time due to the architectural changes, the subsequent 104, 105 aircraft, the first flight time interval will be very small, even lower than the interval between 102 aircraft and 101 aircraft.

Also, to break into the global “open beta”, the C919 large passenger aircraft also submitted a type certificate application to the European Aviation Safety Agency (EASA). In mid-2016, EASA has begun to accept, after three years of hard “Long March”, C919 large passenger aircraft has won the “International Pass” is insight.

The road to the industrialization has a long way to go

Of the 815 orders for the C919 large passenger aircraft, 34 were ordered abroad. The main domestic orderers are China Eastern Airlines, China Southern Airlines, Air China, Hainan Airlines, as well as leasing companies such as Bank of China Leasing, ICBC Leasing, and Bank of Communications Leasing.

“The short- and medium-range twin-engine passenger jet market has the greatest demand, and the domestic market is very strong, so the market risk of this type of aircraft is very small.” Xu Ning, a doctorate in aircraft design at Beihang University, believes. Judging from the voyage of the C919 large passenger aircraft, the domestic market is sufficient to support the success of the project, but it is clear that the C919 large passenger aircraft is aimed at the world.

The global large civil aircraft industry has great potential. It is estimated that in the next 20 years, there will be a total of 35,000 large civil aircraft to be delivered globally, with a minimum valuation of US $ 5 trillion, while China will need about 6,000 new passengers and cargo aircraft, valued at the US $ 945 billion, accounting for the total global demand for new aircraft during the same period 18%. Before the birth of the C919 large passenger aircraft, such a high market value will be included in the pockets of Boeing and Airbus. China can only “make wedding dresses for others” on the low-end production line and earn meager profits.

He Dongfeng, Chairman of COMAC, said: “The manufacturing process of the C919 must be customer-centric and meet the needs of customers. Its manufacturing resources come from the world, the market faces the world, and the competition faces the world.”

The ultimate goal of the C919 large passenger aircraft is to enter the international market as soon as possible. From the perspective of COMAC’s participation in the Singapore Airshow for five consecutive years, COMAC plans to first develop the Southeast Asian market before entering the world. According to estimates by the International Air Transport Association, the number of air passengers in the Asia-Pacific region may reach 3.5 billion by 2036, more than double the total of North America and Europe, and the C919 large passenger aircraft will be promising.

Experts predict that by 2035, C919 large passenger opportunities will form a complete product chain.