Coherent, a powder bed fusion system manufacturer, and exocad, a dental CAD/CAM software developer, have announced a partnership that they believe will simplify and improve the digital workflow of dental professionals. The collaboration will see the development of a simple data interface between exocad’s DentalDB software and Coherent’s DENTAL COCKPIT slicer, making the production of metal dental restorations more efficient.

Novica Savic, CCO of exocad, stated: “As a leading software developer for the dental industry, we work closely with many of our clients to understand their needs and requirements. Streamlining the process between the design and production of dental parts is key to making their work easier.”

Digital dentistry

Digital software platforms are crucial for modern dental professionals to provide the best possible dental care. One very important aspect of this is the compatibility of the software used within a practice and the laboratory, as this determines efficiency and reliability.

Last year, Coherent released the DENTAL COCKPIT, a 3D slicer for use with the company’s metal powder bed fusion system, the Coherent CREATOR. According to Coherent, the DENTAL COCKPIT simplifies the preparation and production of parts with a user-friendly and intuitive design, and introduces significant time efficiencies.

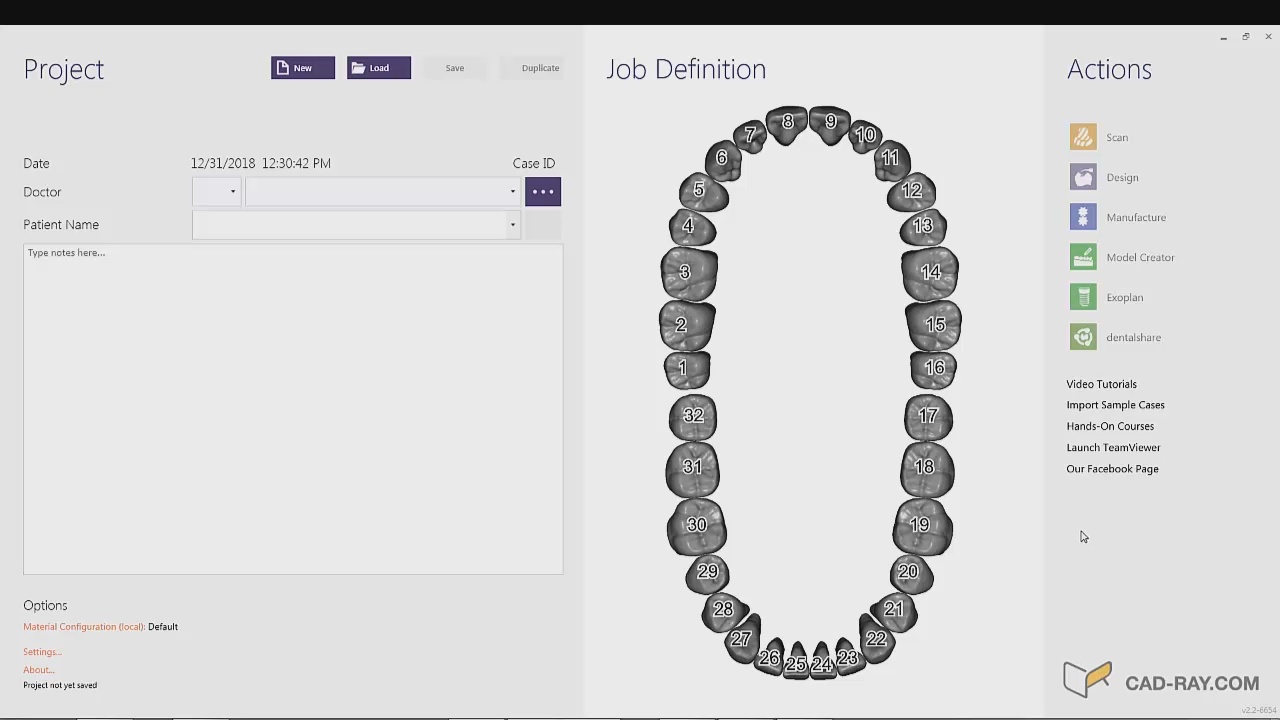

On the other end of the workflow, DentalDB is exocad’s CAD and case management software for dental applications. DentalDB is one of the more popular design applications with dental professionals due to its flexibility and abundance of features.

Streamlining digital workflow through compatibility

Manufacturing on Demand

The collaborative effort aims to develop and implement a simple data interface between the two software platforms. The data interface will allow users to export exocad designs into Coherent’s DENTAL COCKPIT slicer with a single click. DENTAL COCKPIT will then pre-process the models in accordance with optimized default parameters. Data for the production of these models with the Coherent CREATOR using Ti and CoCr materials will then be automatically generated. With the data interface, patient data can be loaded and printed in two simple clicks as DENTAL COCKPIT automates the tagging, supporting, slicing and nesting processes in the build area.

Akira Schüttler, Systems Integration Engineer at exocad, said: “The DENTAL COCKPIT solution from Coherent is an innovative development for the production of metal parts on the CREATOR 3D printer and we are delighted to cooperate on integrating the two digital platforms to simplify the digital workflow.”

Ludovico Camarda, Managing Director Coherent Dieburg, added: “We are delighted to announce this cooperation with exocad. It is a natural fit to make these two dental software platforms more easily compatible. It will also ensure users of exocad and the DENTAL COCKPIT with the CREATOR gain huge efficiency and productivity rewards, with simplified workflows that ensure better outcomes for their dental patients. It’s a win-win situation.”

Coherent and exocad, although popular, are not the only players in the dental AM software market. Shining 3D, a Chinese AM company, has previously announced a partnership with AGE Solutions, an Italian dental software developer, to create a new orthodontics design software for use with 3D printers. Elsewhere, California-based uLab Systems has developed an FDA cleared dental aligner planning software, which enables the rapid 3D printing of clear orthodontic appliances.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Kubi Sertoglu

Leave A Comment