This year, one startup shook the industry with the potential to push 3D printing to the next level and it wasn’t Carbon3D. Though Carbon3D’s ultra-fast CLIP technology has huge implications for the potential of 3D printing, it can only satiate the desire for speed and instant gratification. Still, CLIP will be, at least as it was presented to the public, a method for producing parts. Voxel8, however, is working towards the ability to produce, not parts, but completely functional objects with their Developer’s Kit, a unique desktop platform for 3D printing electronics and other multi-material objects. And, now, the Boston-based Harvard spin-out has obtained $12 million to push this technology even farther.

“There are two pathways that we’re going to be executing on with that funding,” Dr. Lewis began, “First and foremost, we’re going to be using those funds to ramp up manufacturing of the Developer’s Kits, for which we’ve received pre-orders across multiple industry sectors: aerospace, automotive, consumer electronics, and beyond. We’re still targeting shipment of these pre-orders for Q4 of this year.” Manufacturing of the Developer’s Kits will be performed in house, which ensures the quality of each product, while also educating the startup as to the proper methods for building a quality assurance operation.

Then came the really exciting news, “And, at the same time, there’s a lot of market pull for our next advanced industrial-scale – what we’re calling – a ‘pro printer’, if you will. So, some of those dollars will go towards bringing that product to market, as well.”

What is the Developer’s Kit?

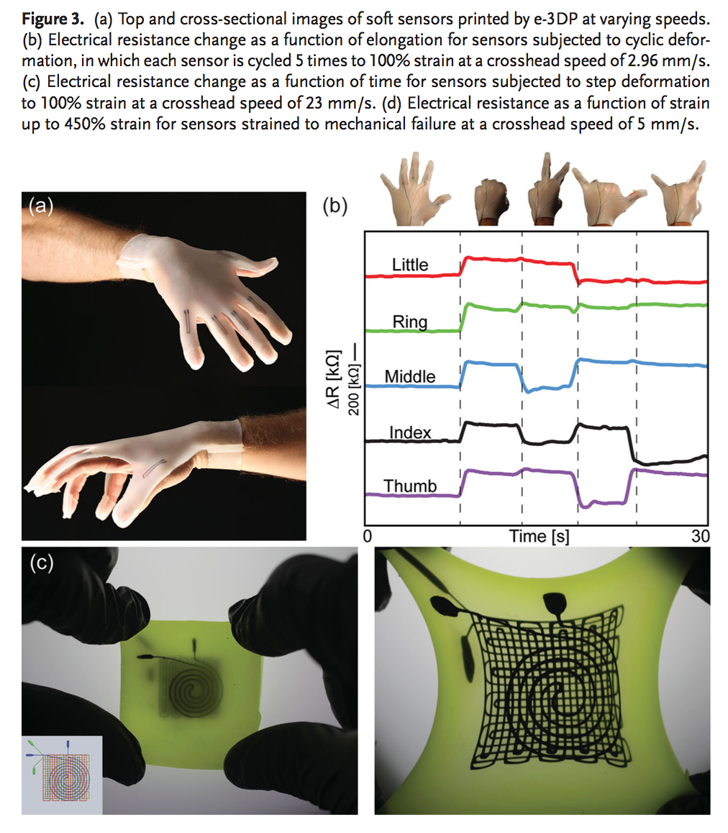

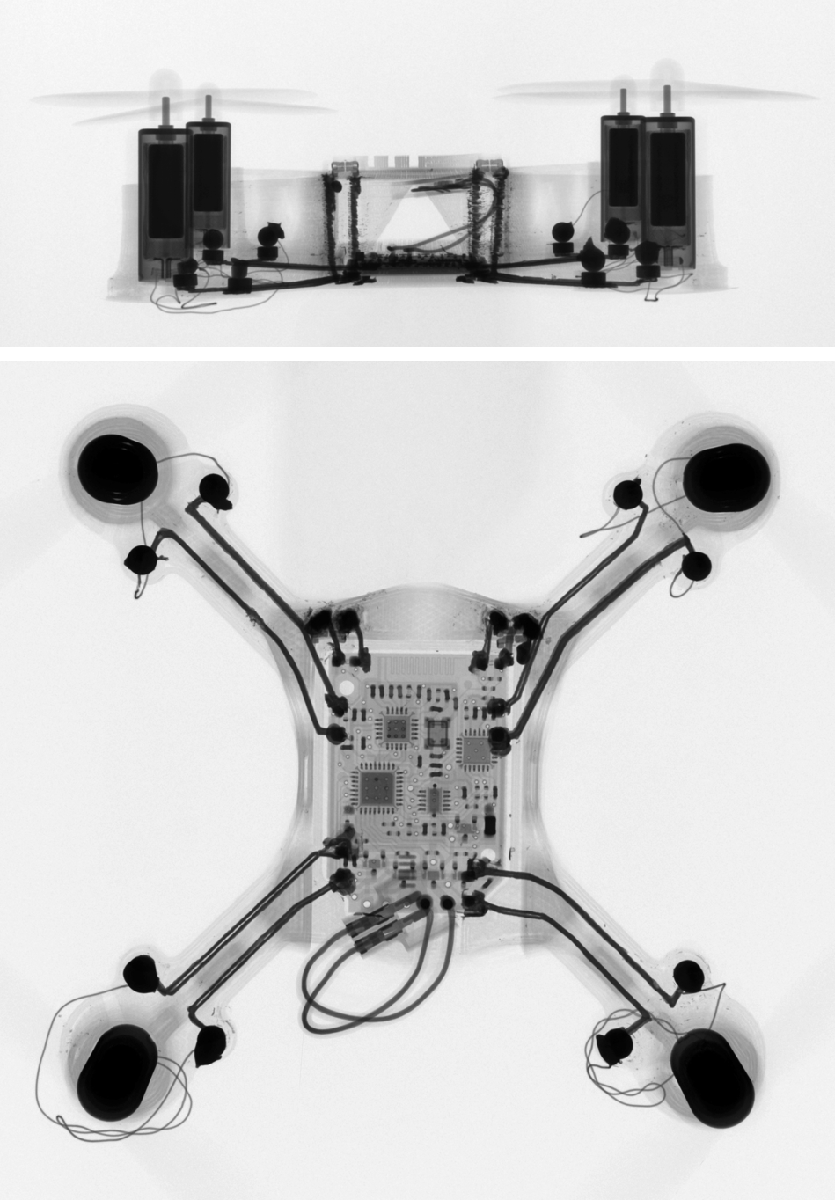

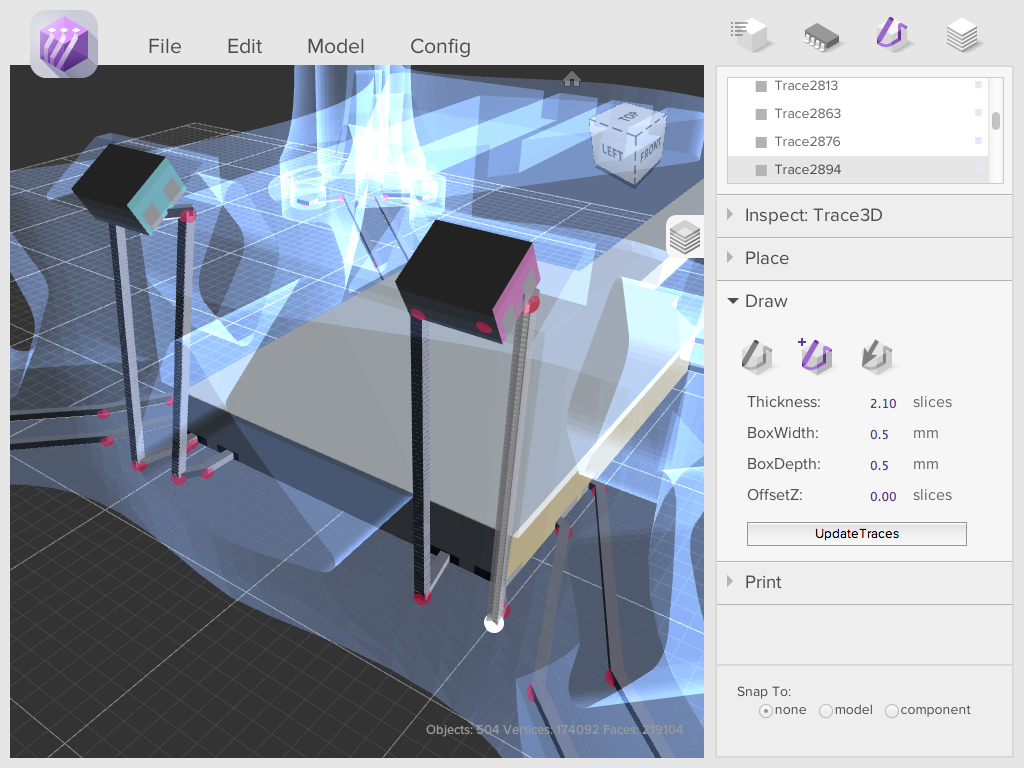

Currently, the Developer’s Kit works with two materials, PLA plastic and conductive silver ink, to combine traditional fused filament printing with electronic circuitry. Plastic is extruded out of one portion of the printhead and the conductive ink is dispensed out of another to create electric traces. With the help of Autodesk’s Project Wire, users can drag and drop components, such as transistors and resistors, into a CAD model so that, using Voxel8’s proprietary toolpath software, the printer can pause at the appropriate moment during a print task for the manual embedding of these electronics within the print. Printing then continues and, in the end, the user has a fully-functional object. The startup showcased this ability by 3D printing a quadcopter that, once completed, was able to fly off of its printbed.

There are already conductive filaments on the market, meant for 3D printing projects that involve electronics, so I asked the Voxel8 founder to elaborate on the difference between their conductive ink and the filaments currently being sold. Lewis replied, “Right now, so, if people get desktop printers that use filaments – They’re typically carbon-filled, so they have really low conductivity because carbon particles are much less conductive than metallic particles. So, we’re developing these silver-based inks. First of all, they have this higher-conductivity particle phase and, secondly, they’re not based on polymer filaments. It’s really a low-viscosity solvent.”

She goes on to discuss the dispensing mechanism that makes the Voxel8 platform possible, “It’s an extrusion-based, pneumatic dispenser and that’s one of the really big innovations on the desktop printing platform. We’re moving beyond fused filament deposition and we’re complementing that with pneumatically dispensed inks. That opens up, basically, every ink design we’ve developed in my lab at Harvard, all of which are dispensed in that fashion. So we can bring a broad range of materials to the printing platform.”

Combining multiple materials, Oliver adds, gives users the ability to interface objects created by the Developer’s Kit with other technologies, “The ability to print multiple materials together really works well with interfacing with other technologies. We can print conductive traces. We’re able to interface with a large amount of electronic components out there. So, you can see the power of these electronic components within a 3D printed object and we look to expand that in the future. The key here though is being able to print multiple materials together on the same printer. And that allows you to interface with more and more technologies, really expanding the dimensions of what’s on the printer.”

Challenges in Developing the Developer’s Kit

As you might imagine, bringing the hardware, software, and materials together in just the right way to pull off multimaterial electronics printing is no easy task. Dr. Lewis describes the different obstacles Voxel8 has overcome to bring about this novel device, “The challenges we’re tackling on all fronts. It’s materials integration: trying to integrate disparate materials, like thermoplastics with conductive inks. It’s the hardware, which brings together multiple printheads.”

She continues, “And this, frankly speaking, is also on the software side. We’ve been very fortunate to partner with Autodesk, through their Spark platform on the software Project Wire, which allows designers and engineers to actually create, in their CAD models, the ability to embed these conductive features and electronic parts. But then Voxel8 has proprietary software for slicing for toolpath planning and, as you start to think about co-printing multiple types of materials – the matrix, the plastic, and the conductive materials – that toolpath planning is also very important.”

The CEO concludes, “So, tertially speaking, there’s challenges across all three key components of the printing platform – the materials, the hardware, and the software. And Voxel8 is tackling those.”

The Voxel8 Pro

Details about Voxel8’s “pro printer” are still “locked down” at this point, according to Lewis, but Dan Oliver was able to elaborate on the fact that it will be developed based off of input from their first Developer’s Kit customers, “We’re working with our current customers and our initial partners to effectively guide the design of the next, pro platform. Michael, as you and I have talked about in the past, the idea with the Developer’s Kit was to get them out there and to spark people’s imagination. We’ve gotten really great feedback of what people would want down the line and they’re super excited to get their printers. So, we’ll be working with those initial customers to help define what those next types of platforms would look like and make sure we’re executing on our customers’ input.”

As exciting as conductive ink is, my mind was reeling with possibilities for the next generation machine – which I label in my mind “the Voxel8 Pro”. Dr. Lewis’s work with her Harvard lab and, previously, her University of Illinois lab, fill the spectrum of materials sciences and 3D printing, from 3D printing microscale lithium ion batteries to fabricating channels for possible uses with bioprinting. Though some of this work may not necessarily make it into her startup, the pneumatic dispenser at the heart of Voxel8’s hardware was developed right out of her lab and opens the doors to a huge array of materials for desktop printing.

So, while the Voxel8 Pro may be an overall improved machine, it will also likely have the ability to print a greater variety of materials, including epoxy and elastomers. Lewis explains, “It’s not only the printing platform – you know, bringing an improved platform with higher resolution and these kinds of things to market – but it’s also a broader palette of materials. Releasing a customized set of materials that best meets our users’ needs. In addition to the conductive ink that’s going to be launched with our Developer’s Kit, we’re going to broaden the matrix materials to include epoxy and elastomeric materials. Just a broader palette of matrix and functional inks.”

Who Wants to Buy a Voxel8 Printer?

The ability to 3D print electronics and, in the future, elastic materials with rigid materials, has, naturally, garnered a lot of attention. Without disclosing their customers, Dr. Lewis was able to speak to one possible application for their platform, “We can talk generically about some use cases. We’ve been given, by prospective customers and people that have already pre-ordered our developer’s kit, applications in the biomedical space – we see hearing aids as a big target opportunity. There are use cases in almost every vertical I’ve mentioned already that we’ve either received CAD files for or have had discussions.”

As enticing as it would be know who these clients were, Oliver was quick to point out that the diverse industries represented by their clients indicate just how widely applicable the Voxel8 platform could be. “The most interesting thing to talk about here is our customer list,” Oliver explains. “You have the leading companies in automotive, aerospace, consumer electronics, medical devices, and apparel. We have really interesting companies that have bought the printer, so, the use cases span the gamut of those customers.”

Dr. Lewis added, “We should also mention the defense companies, because they’re also prominent early adopters.” In fact, Voxel8 has already received interest from some pretty important customers. Among them is In-Q-Tel, the non-profit venture capital arm of the Intelligence Community, who have just contributed even more to the startup. As you may have guessed, this work is top secret, but the investment speaks to the profound power that multi-material electronics 3D printing has.

Voxel8 has also signed an agreement with the government-focused MITRE Corporation, for whom the startup is researching the possibilities of 3D printing antenna arrays. Of course, as they’re doing this work on behalf of an unnamed government sponsor, this work is also under wraps. “We can’t really say more than that we’re working on 3D printed embedded antenna and antenna arrays. That’s all that we’re at liberty to say. But I think you can imagine that what our printer can deliver is three-dimensional antenna designs that simply can’t be manufactured by other means.”

Dan Oliver, however, was able to elaborate on the benefits that 3D printing brings to fabricating antennas. “Standard antennas are made on standard PCB boards, which are two-dimensional. Antennas themselves, though, really live in the three-dimensional world. So, we’ve created these large-footprint antennas by forcing them to live in two dimensions,” Oliver says. “But what we’re really excited about is being to create these high-performance antennas that are three-dimensional. And ours is one of the few technologies that’s able to do that.”

Voxel8 2.0 & 3D Assembly

These projects will only be pushed further with the latest funding round and the future of the technology looks bright. At the moment, electronic components must be manually placed into an object during the printing process, but this is definitely a feature that could be made obsolete. Lewis and Oliver explain that all of the technologies to automatically fabricate fully functional electronic devices already exist, but separately from one another.

When asked about the possibility of automatically inserting transistors and resistors into 3D printed objects, Lewis responded, “Yes. At this point, with our desktop printer, we’re already embedding these kinds of functional objects. We’re doing it by manual pick and place, but it’s very easy to conceive that, on our road map, transitioning to automated pick and place is the future. So, absolutely, that will be accommodated by our printing platforms.”

Oliver elaborated, “One thing we think about a lot is, ‘what is the next printer going to look like?’ And the answer to that is to ask what is needed. Effectively, the technologies to print that all automatically exist separately, if you combined our technology with pick and place technology. So. it becomes, not solving the technological problems – though we still have work to do there – it’s what things we need to put together that’s really going to push this to the next level.”

In fact, Oliver says, there is a lot going on behind the closed doors of the Voxel8 lab that just aren’t ready to be launched with this first product. “So, something like the quad copter. We’re already doing that. We don’t have an automatic pick and place system because that doesn’t make sense for the developer’s kit. So, a lot of these things that seem futuristic, we’re doing every day out back in the lab.”

But, when, I wondered aloud, will someone be able to take a Voxel8 printer and fabricate a quadcopter completely without manual intervention. Dr. Lewis gave me, what I thought, was a very promising response, “I would say within the next few years is our target.”

A Team Effort

All of this news and the opportunity to speak directly with the innovators behind what has been, to me, the most important development in 3D printing so far this year, was truly exciting. And, from the sound of it, Dr. Lewis was on an exciting ride herself. “I think it’s really gratifying to see some of the ideas we’ve worked on in the lab to move out into the commercial sector and really have a chance to have a major impact in that way. For me and the research group, it’s really exciting to have this opportunity.”

Lewis says, though, that this isn’t a one-person operation, “I really want to emphasize that that wouldn’t be happening without the amazing team we have at Voxel8. The boundaries between my lab and Voxel8 is one where we’ve done lab-based research at Harvard and at my former institution at Illinois, but to take that to the next level and do commercialization, the team at Voxel8 is just doing incredible well. You know, with Dan Oliver and with the three other team leads: Michael Bell, Travis Busbee, Jack Minardi – materials, hardware, and software – it’s really just been tremendous… Dan, of course, has been pushing forward on the marketing side and driving the whole team forward. The four co-founders are incredibly invaluable… The energy, the drive, the talent and expertise that Voxel8 have is really just making this happen.”

The new funding, of course, allows them to build this team even further, Lewis says. “We’ll definitely expand the team. We’ve already made some really exciting hires from some IT companies, like iRobot, Philips Medical, Warby Parker, and DEKA, which is behind Dean Kamen’s Segway. We’ve been able to attract a lot of really awesome talent and that’s only going to continue to build as we go forward with the new funding.”

What they do next, whether it’s “locked down” or not, is sure to be amazing. In some ways, what’s been left unsaid – potential materials and customers – really paints a powerful picture. Without knowing who or what will be involved, my mind is left to illustrate a wild painting that sees Nike printing smart orthotics, the CIA building tiny spyplanes, or e-NABLE 3D printing bionic arms. Then, Dr. Lewis leaves me with the conclusion, “It just comes back to our driving motivation: to establish 3D printing platforms that enable the integration of form and function. So, to go beyond prototyping shapes or complex forms and to really create things that have embedded functionality.”

Leave A Comment