CLIP based 3D printing technology developers Carbon are integrating the Oracle Cloud to manage HR, customer experience, financial services, and their supply chain. Moving to The Cloud will help streamline processes behind the scenes to help Carbon deliver to more valuable services customers and employees.

A 360° customer view

Oracle is a multinational software and technology corporation that, like Carbon, is based in California.

As Oracle group vice president of strategy, Gretchen Alarcon, explains, moving to the cloud will facilitate Carbon’s vision for “every member of their company to have a comprehensive 360-degree view of each customer”.

Alarcon continues:

We are pleased to work with [Carbon] to ensure our cloud applications deliver this visibility to support their ongoing success. Oracle’s enterprise-grade cloud applications work together seamlessly to empower everyone from a relationship manager to Carbon’s CEO to see how all parts of the business are performing.

What it ‘The Cloud’?

The Cloud is an internet database that allows its users to share access to resources, i.e. applications, documents, 3D models. In consolidation of their 123D range of applications, Autodesk CAD/CAM 3D modeling software has also moved to The Cloud.

Chris Hutton, Carbon’s director of business operations sees the cloud-based Oracle as “a future-proof […] solution that could scale as we grow.”

Continuous 3D printing ‘100 times faster’ than typical 3D printing

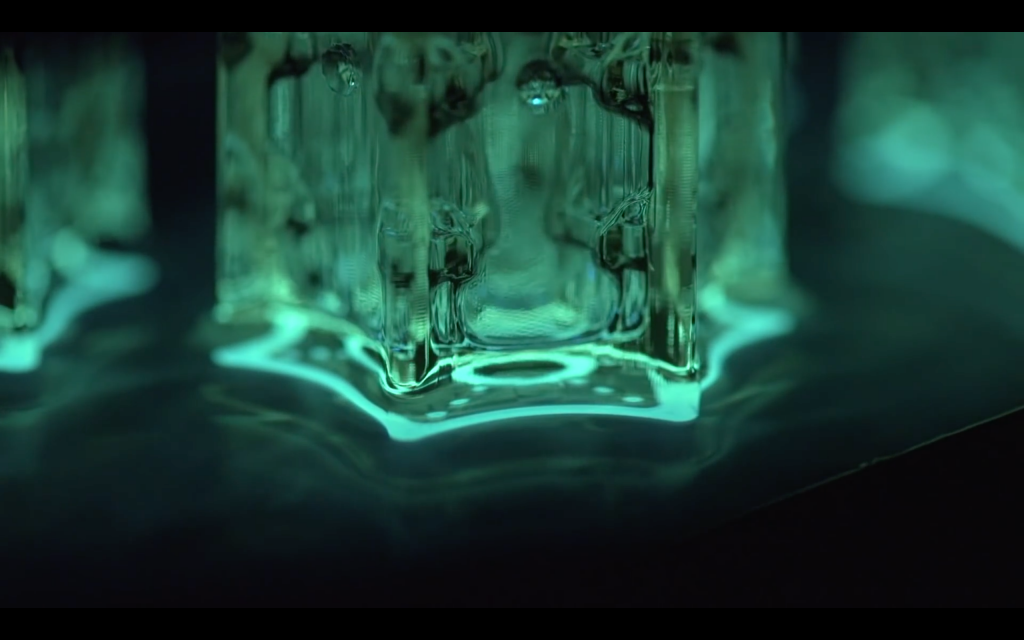

Continuous Liquid Interface Production (CLIP) is Carbon’s proprietary 3D printing process. It works with works with photosensitive resins as vat polymerization technique.

What makes the process up to 100 times faster than other stereolithography methods is that CLIP operates continuously, rather than layer-by-layer.

Carbon’s M1 desktop 3D printer is capable of working with five different materials. PR is for rapid prototyping, and CE a polymer than can withstand temperatures up to 219°C (426°F).

Clip via: Carbon3D.com

Elastomeric Polyurethane (EPU) is the highly flexible plastic seen above, and RPU its rigid counterpart.

Finally, FPU is a material in between EPU and RPU, combining flexibility with strength.

If Industry readers would like to acknowledge Carbon with an award, they can be nominated for one of our awards here.

Featured image shows TRex models 3D printed by Carbon in their PR resin. All photos in this are provided courtesy of Carbon.

Leave A Comment