Aerospace manufacturer Boeing has a qualified 3D printer OEM Stratasys’ Antero 800NA thermoplastic filament for flying parts. In this way, PEKK-based polymers can now be used to additively manufacture end-use components on Boeing aircraft.

Scott Sevcik, Aerospace Vice President at Stratasys, states: “Boeing has recognized the tremendous utility of Antero to meet applications that couldn’t have been 3D printed before. Additive manufacturing has tremendous benefits for simplifying aerospace supply chains both in original equipment and MRO, but robust materials for meeting challenging flight requirements have been needed.”

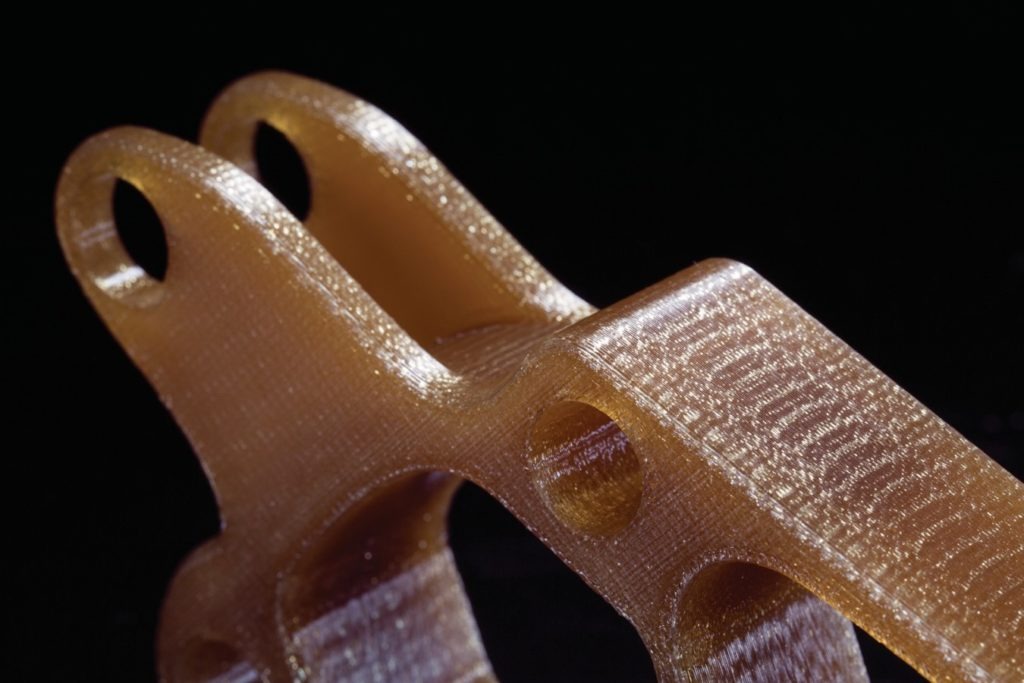

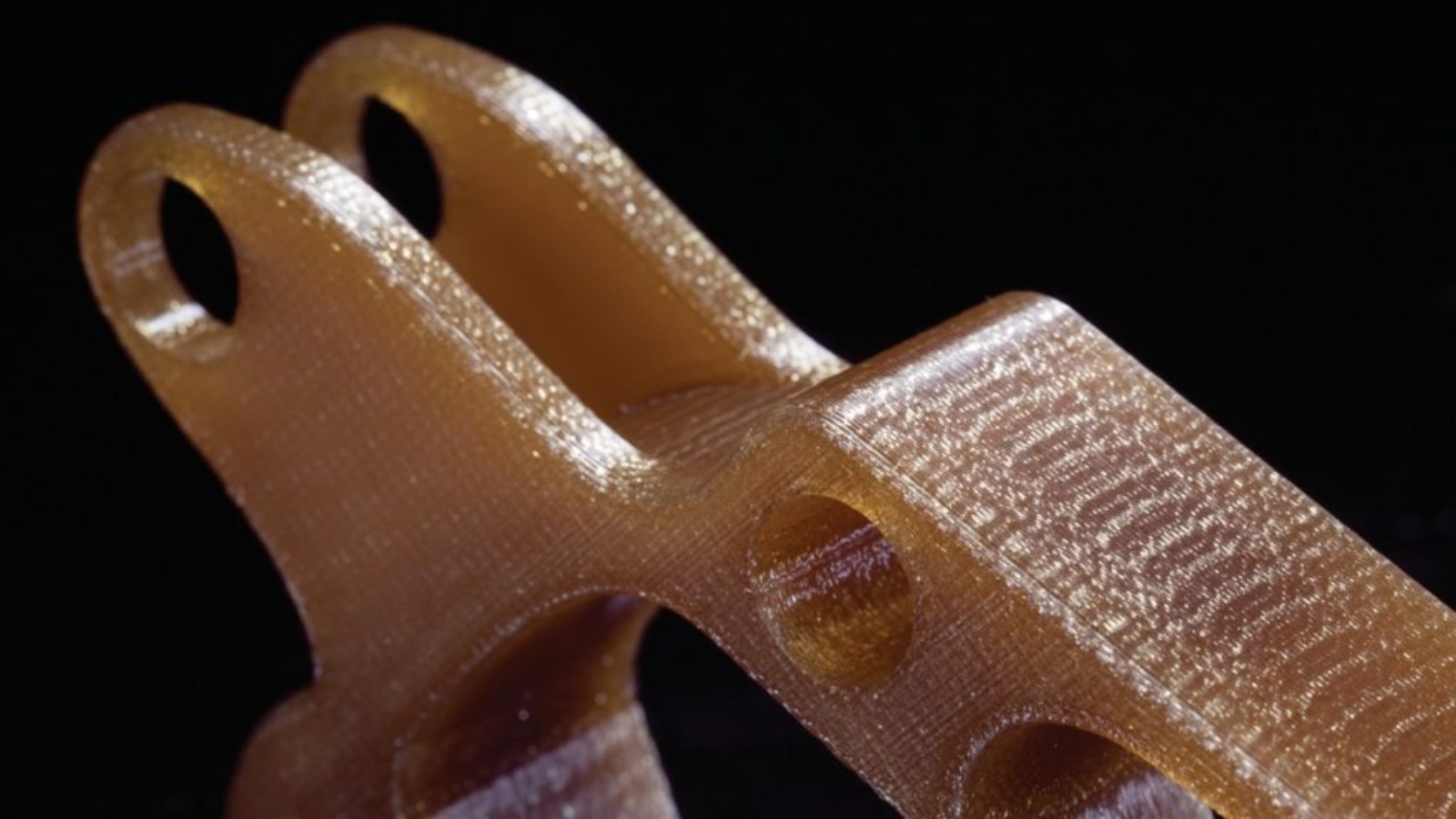

Antero 800NA polymer

Antero 800NA is a high-performance polymer-based on PEKK, specifically designed for Stratasys’ industrial FDM 3D printers (such as F900 and Fortus 450mc). For customers who choose to use the company’s on-demand manufacturing service Stratasys Direct Manufacturing, it can also be an important choice. Another filament in the Antero series is 840CN03, which has static dissipative properties.

800NA has a tensile strength of 93MPa and an elongation at break of 6%. It is designed to combine PEKK’s excellent mechanical properties and low outgassing performance with the design freedom of FDM 3D printing. The filament’s high strength, heat and chemical resistance, toughness and wear resistance make it an excellent substitute for metals such as aluminum in aerospace applications.

After extensive performance testing, Boeing released the BMS8-444 specification and now includes Antero 800NA in its Qualified Product List (QPL). This is Stratasys’ first material, and its Boeing has chemical resistance and fatigue resistance. For example, the filament has previously been used to make prototypes of air ducts, where its resistance to jet fuel and lightweight will work well.

Boeing and additive manufacturing

Over the years, Boeing has increasingly participated in the development of various additive manufacturing technologies and materials, which is undoubtedly the result of technological progress in the industry. The company completed the first flight of its 777X jet in early 2020, which is powered by dual GE9X engines from GE Aviation. As we all know, these engines contain more than 300 3D printed parts, including the famous LEAP fuel nozzle.

Recently, Boeing and the Scottish National Manufacturing Institute (NMIS) announced that they would start a research and development project costing 11.8 million pounds to advance various manufacturing technologies in Scotland. To promote the plan, a lease contract has been signed with the real estate investment company Canmoor to lease a 60,000 square foot warehouse in Westway Park in Renfrew. The plant will have a dedicated area dedicated to promoting the use of additive manufacturing in the country.

Leave A Comment