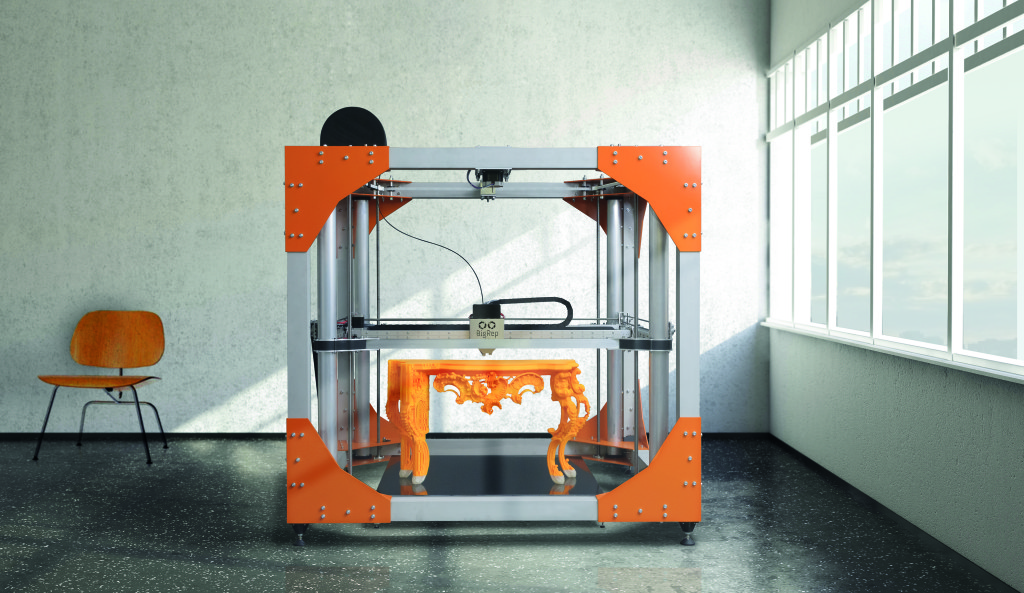

At EuroMold 2014 in Frankfurt this coming week, Berlin based BigRep will introduce the latest iteration of its huge 3D printer platform —BigRep ONE.2. With a working volume of 1100 x 1067 x 1097 mm (1.3 m³) it is, the company claims, the biggest serial 3D printer available. The original – beta verseion – of BigRep ONE was introduced earlier this year in February — I first saw it in March at Inside in Berlin — and it certainly caused a stir. The thing is ‘mahoosive’ as my daughter would say! The premise of BigRep is to stride past the conventional hand-sized models that the 3D printing community is used to and to offer a platform that enables its users to realize parts and molds at full scale — printed out directly.

Typical target markets and those that are expressing serious interest in BigRep include furniture designers and architects. The company claims that these customers will find BigRep ONE.2 will be more affordable than other full-size printers in terms of purchase and, significantly, maintenance.

At EuroMold, BigRep will strive to demonstrate to as many people as possible how the BigRep ONE.2 is perfectly able to produce molds as well as prototypes and models — to the notoriously industrially biased visitors who attend this show in large numbers. One example BigRep cites is that the ONE.2 platform is capable of 3D printing full-scale molds for glass vases. With these molds, a glassmaking factory realized vases at a size of 40 x 60 cm. These vases, along with the molds and of course the BigRep ONE.2 itself will all be exhibited during the event in Frankfurt in Hall 11, Booth F86.

Lukas Oehmigen, CTO and founder of BigRep commented: “With our latest project we are demonstrating how 3D printing can be used in manufacturing. Our objective is to make full-size 3D printing affordable for everyone – in design, prototyping and manufacturing. In this class, we are setting the standards. Costs for the printer and filament are far below those of our competitors. Thus, we will revolutionize manufacturing and make it more flexible.”

Leave A Comment