Today, leading 3D printing solutions manufacturer BCN3D has launched a new 3D printing technology to advance alongside its FFF solutions: Viscous Lithography Manufacturing (VLM) TM. This never-seen-before technology has been derived to specifically address BCN3D’s vision of unlocking manufacturing autonomy, where all manufacturers can experience full control over every stage in their production processes with AM solutions using highly viscous resins.

VLM comes as a breakthrough from 3 years of dedication from BCN3D’s R&D team as a game-changing way of surpassing stoppers such as initial investments in money or space, mechanical properties not up to standard, or incapability of large batch production. It is through the fresh perspective of using high viscosity resins for better mechanical properties, in combination with this huge leap forward in productivity and accessibility, that ultimately satisfies all demands to unlock manufacturing autonomy.

“If 3D printing is to be the future of manufacturing, and what leads us towards local production, customization, control of supply chains and sustainability, all the players in the industry should be pushing in this direction. At BCN3D, we think that today is the first step in achieving this goal with the new Viscous Lithography Manufacturing (VLM) technology. We want to show 3D printing in a new light so that it becomes the pivotal point of manufacturing” said Xavier M. Faneca, CEO of BCN3D.

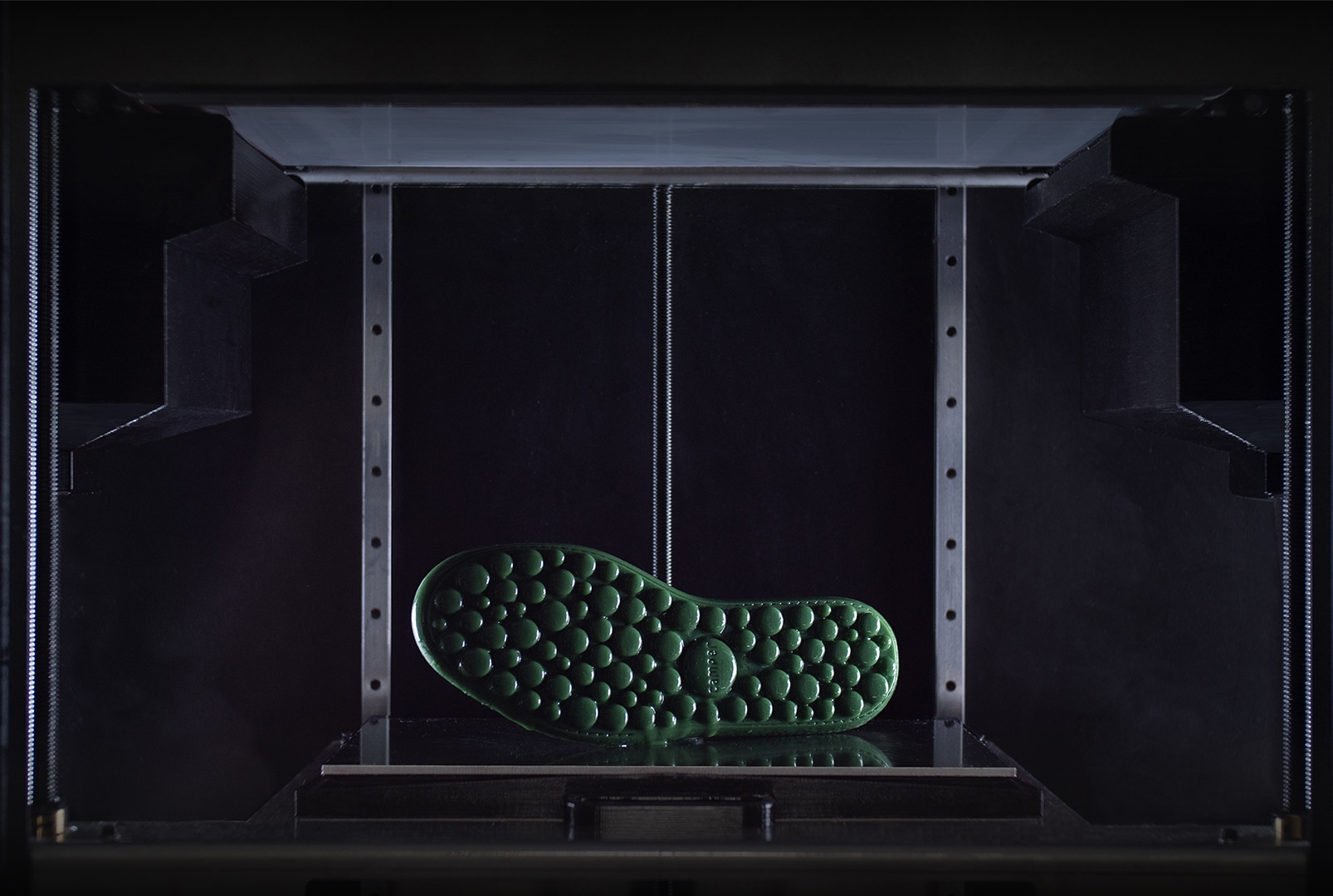

Highly viscous resins for superb part performance VLM is a patented lithography-based 3D printing process that laminates thin layers of high viscosity resins onto a transparent transfer film, producing high-performance parts rapidly and affordably. What distinguishes VLM from other resin technologies on the market is its ability to process 50x more viscous resins than the industry standard.

The mechanical system allows the resin to be laminated from both sides of the film, making it possible to implement strategies to speed up printing times or even to combine different resins to get multi-material parts and easy-to-remove support structures. Without a strict low viscosity constraint, chemical companies obtain the freedom to formulate, as a whole new set of ingredients and modifiers can be added in the resin to achieve the desired effect on thermal and mechanical properties. VLM processes resins that obtain 3x the amount of impact resistance for rigid materials and a 200% increment in tear strength compared to industry-standard formulations.

Specialty materials company Arkema has been part of the process, through a Joint Development Agreement (JDA) in which the two companies are co-developing new materials capitalizing the singularities of VLM to obtain properties that can’t be reached with other resin-based 3D printing processes. As a global key player in the 3D printing industry and a pioneer in designing high-performance photocurable resins, Arkema utilized its experience spanning decades to ensure resins for VLM were of the highest quality. “Thanks to the proven capability of VLM to manage very viscous resins, we envision a great prospect to develop new building blocks and enable game-changing formulations to meet applications requirements that have not yet been reached with existing photo cure technologies”, said Hélène Egret, Europe 3D Market Manager at Arkema.

Manufacturing on Demand

BCN3D has also partnered with Prodrive, world-renowned motorsport and advanced technology company and one of the first in the world to put VLM technology to the test. They’ve been assembling end-use parts made with VLM mounted directly on cross-country cars. “VLM technology seemed to combine all the best features of the different Additive Manufacturing technologies, and even offer some unique advantages. For Prodrive, materials are the key to making durable end-use parts. VLM allows us to continue to use the engineering materials that we know and love, but instead in significantly finer resolution in all three directions, and the material is much more homogeneous, making the finished parts behave much more like a traditional injection molded part”, said Callum Harper, Design Engineer at Prodrive.

By using a light source consisting of UV light and an LCD screen, VLM delivers a constant time per layer, regardless of whether we are printing one or 100 parts at once. Furthermore, since it is not limited by the vat dimension, a complex temperature, or tricky components, all that’s needed to scale up is a bigger LCD screen. This combination of a quick layer time and a large surface area makes VLM the most productive additive manufacturing solution on the market using viscous resins.

BCN3D’s partnership with automotive glass manufacturer Saint Gobain illustrates these benefits perfectly in a use case where 7000 positioning fixtures have been fabricated in 7 days with VLM, for 0.79€ per part and a subsequent annual saving of 70.000€. “VLM technology has empowered us to see significant improvement in the future. Our main goal is to reduce our dependence on external mechanization suppliers and do it internally instead with technologies such as VLM. Doing so is what would give us the power of manufacturing autonomy”, said Alberto Rodriguez Fernandez, World Class Manufacturing Manager at Saint Gobain.

There’s no denying that 3D printing has evolved from a rapid prototyping tool into a clear trend in manufacturing – all that was missing was an affordable solution to reach all corners of manufacturing, from small to medium-sized businesses. Unlocking manufacturing autonomy using 3D printing shouldn’t be just for Fortune 500 companies, but for every single business that develops and manufactures concepts or products, in any industry. VLM-based solutions will be under 50.000 euros, with a compact footprint, no dedicated space or critical infrastructure. This low entry barrier, in combination with its big printing volume and high throughput, puts the fixed cost of the solution ahead of the rest. By implementing the use of VLM, the cost per part is significantly lower than those of powder-based and resin-based technologies.

VLM also uses monocomponent resins formulations at room temperature to avoid pot life limitations and speed up setup times. Thanks to its proprietary lamination system, the absence of a resin vat mean that no initial investment of resin is required. What’s more, with VLM, zero waste becomes a reality: designed to filter and recirculate resin, every drop of resin eventually becomes a printed part. To let the entire industry benefit from this breakthrough, BCN3D has devised the Viscous Lithography Manufacturing Technology Adoption Program, aimed at businesses of all shapes and sizes. Its new Applications Center will be operated by dedicated AM specialists and host the upcoming VLM-based hardware solutions. Partakers will join Saint Gobain and Prodrive in being the first to discover the new VLM and experience its full potential for themselves with real 3D printed parts and individual attention on their exact printing needs.

In 2021, the company passionately committed to investing in its new FFF hardware portfolio as well as its software solutions, which sparked the Astroprint acquisition that took place last July and a new logistic center in the USA. BCN3D plans to continue growing its FFF solutions this year and investing in new developments. Its new business unit for VLM will conduct dedicated resources independent of FFF that will instead coexist alongside.

You might also like:

Velo3D FY 2021 revenues top $27 million, growing 45% YoY: “Our performance reflects strong execution as we exceeded our fourth quarter and fiscal year 2021 revenue forecast, surpassed our bookings target and achieved a key strategic milestone as we shipped our first Sapphire XC system which will be a significant driver of our growth in 2022,” said Benny Buller, CEO of Velo3D. “Overall, 2021 was an important and successful year for Velo3D, and I’m enormously proud of everything we achieved. Customer demand for our industry-leading Sapphire systems remains high as we help some of the world’s most innovative companies create the future using our advanced additive manufacturing technology”.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Andrea Gambini

Leave A Comment