Formlabs Raises $35 Million in Series B Funding, Announces Autodesk Partnership 3D Printer Hardware

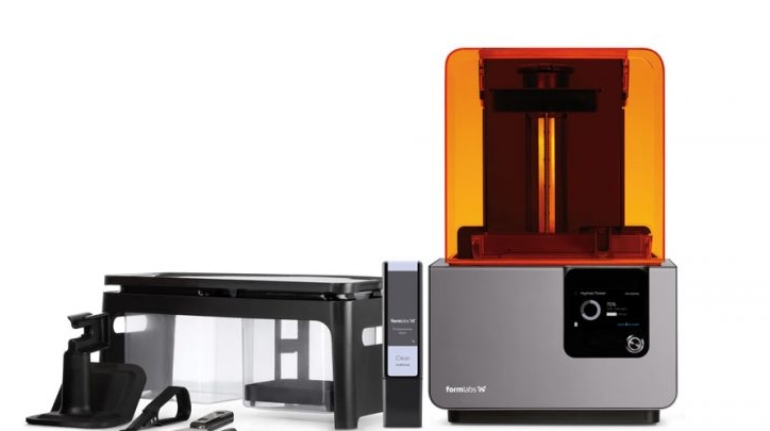

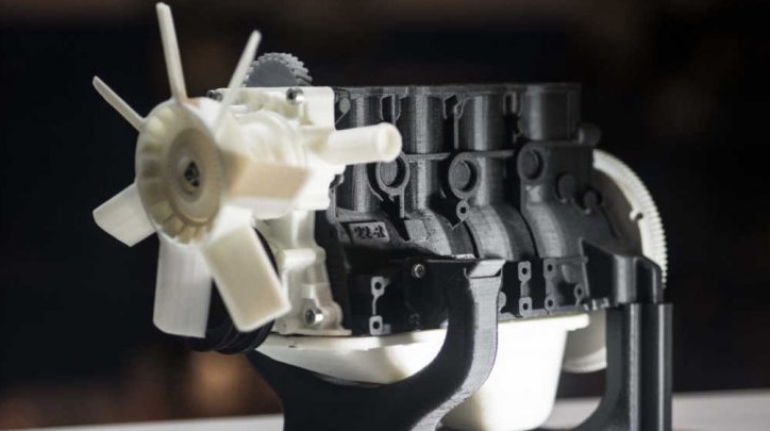

Formlabs, the company founded in 2012 by MIT graduates that changed the SLA market forever when it introduced the first low cost SLA system, has raised $35 million in Series B funding. The round came from Foundry Group and Autodesk, as Formlabs also announced plans to collaborate strategically with the global CAD software leader. The investment includes participation from existing investors DFJ Growth, Pitango Venture Capital, and Pascal Cagni, bringing Formlabs’ total investment to date to $55 million. Beside giving yet another demonstration of the ever clearer potential of 3D printing, these newly injected resource will enable Formlabs to scale its operations to meet growing customer demand worldwide, grow R&D efforts, and to extend Formlabs’ reach in the market and ecosystem. “Formlabs’ efforts over the years in introducing new materials and capabilities have defined the category of professional desktop 3D printing, resulting in significant growth for the company along the way,” said Max Lobovsky, co-founder and CEO of Formlabs. “With the new investment, we’re excited to develop more powerful tools to enable anyone working with 3D content to create remarkable things. Formlabs will continue to grow the stereolithography business and bring new tools to the world to advance our goal of making digital fabrication more powerful and accessible.” Joining Formlabs’ board will be Brad Feld, co-founder of Foundry Group whose investments include MakerBot and Fitbit. Feld has been an early stage investor and entrepreneur for over 20 years and was co-founder of Techstars. “From the moment of its founding, Formlabs saw the opportunity in making professional desktop 3D printing accessible and was a key pioneer in the category,” said Brad Feld, co-founder of Foundry Group. “While the excitement and hype around consumer 3D printing has waned, the professional 3D printing category has had unabated demand, with Formlabs emerging as the leader in desktop 3D printing.” With Autodesk’s investment in Formlabs, the two companies plan to strategically collaborate on software integration and joint marketing initiatives. “Formlabs has brought a lot of innovation and great execution to the desktop 3D printing market, and Autodesk is excited to invest in the company’s future,” said Carl Bass, CEO of Autodesk. “But even more importantly, we’re eager to work together to improve digital design and manufacturing for product designers everywhere.” Pascal Cagni, who was head of Apple in Europe, will be joining as a strategic advisor to help bolster Formlabs’ expansion efforts across the EMEA territory. Through an expanding network of distribution partners, Formlabs’ global reach now extends across five continents in Africa, Asia, Australia, Europe, and North America. With rapid growth across all business fronts, Formlabs has seen 100 percent growth in annual sales for the third consecutive year and is shipping over 1,000 printers a month. Formlabs printers are now the top-selling 3D printers in stereolithography worldwide. Earlier this year, Formlabs acquired Pinshape, the fast-growing 3D printing community online that hosts a flourishing marketplace of 3D designs. Most recently opening a location in Japan, Formlabs now has over 190 employees across offices in North America, Europe, and Asia. About Formlabs Formlabs designs and manufactures powerful and accessible 3D printing systems for engineers, designers, and artists. Their flagship product, the Form 2 3D printer, uses stereolithography (SLA) to create high-resolution physical objects from digital designs. The company was founded in 2012 by a team of engineers and designers from the MIT Media Lab and Center for Bits and Atoms. With its powerful, intuitive, and affordable machines, Formlabs is establishing a new benchmark in professional desktop 3D printing. Formlabs also develops its own suite of high-performance materials for 3D printing, as well as best-in-class 3D printing software. About Foundry Group Foundry Group is a venture capital firm that invests in information technology, Internet, and software startups. It works alongside entrepreneurs to give birth to new technologies and to build those technologies into industry-leading companies. It is located in Boulder, CO but invests in companies across North America. About Autodesk Autodesk makes software for people who make things. If you’ve ever driven a high-performance car, admired a towering skyscraper, used a smartphone, or watched a great film, chances are you’ve experienced what millions of Autodesk customers are doing with our software. Autodesk gives you the power to make anything. For more information visit autodesk.com or follow @autodesk.