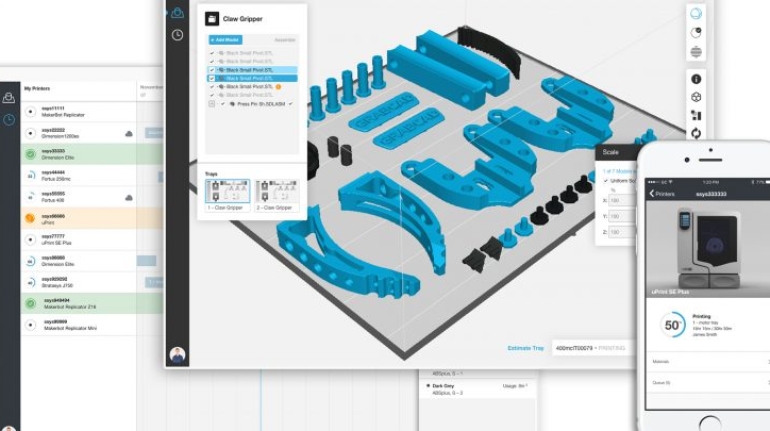

SAP SE today announced it is establishing a global network of 3D printing co-innovation labs to educate and enable customers, employees and partners on the adoption of additive manufacturing as an integral part of the manufacturing production line. Unveiled in conjunction with charter co-innovation partner Stratasys Ltd, the 3D printing and additive manufacturing solutions company, this initiative builds on SAP’s more than 40 years of experience across the industry. Digital manufacturing and co-innovation sites are currently being rolled out across Paris, France; Johannesburg, South Africa; Walldorf, Germany; and Newtown Square, Pennsylvania, and Palo Alto, California, in the United States.