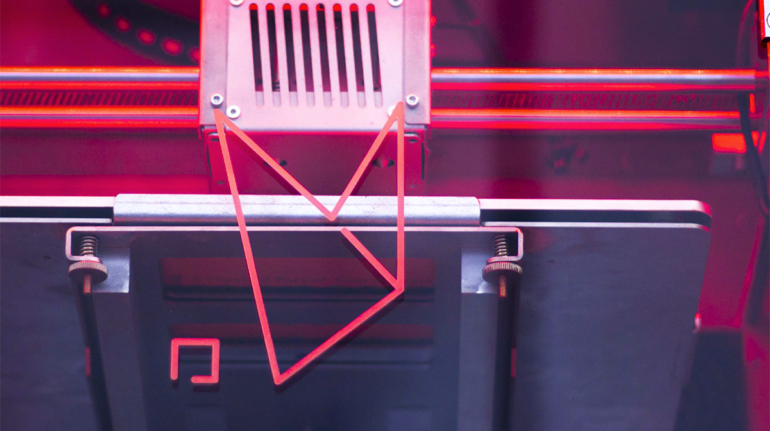

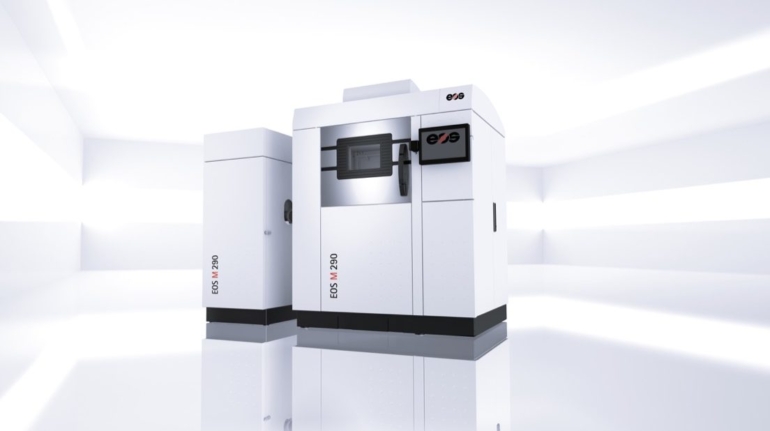

PROGOL3D Presents New Direct Metal Online 3D Printing Service 3D Printing Service Providers

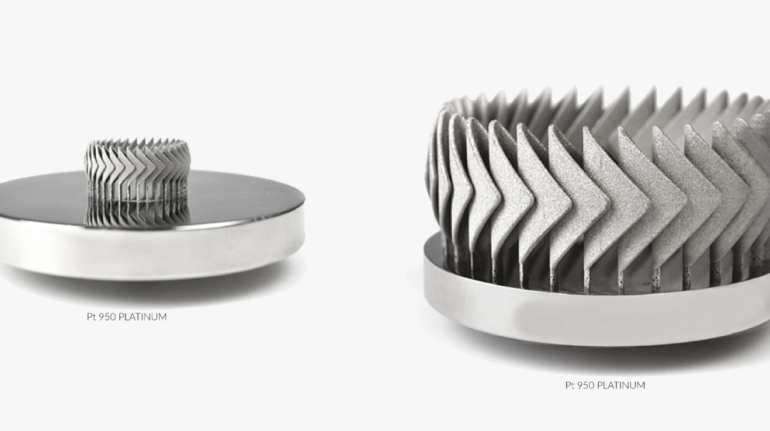

PROGOL3D, a Business Unit of direct precious metal 3D printing leader Progold S.p.A inaugurates a new logo and a new website and new logo design which is aiming to celebrate the company’s recognized authority in the industry.