Lulzbot to Produce 3D Printers During CES 2018 Consumer Products

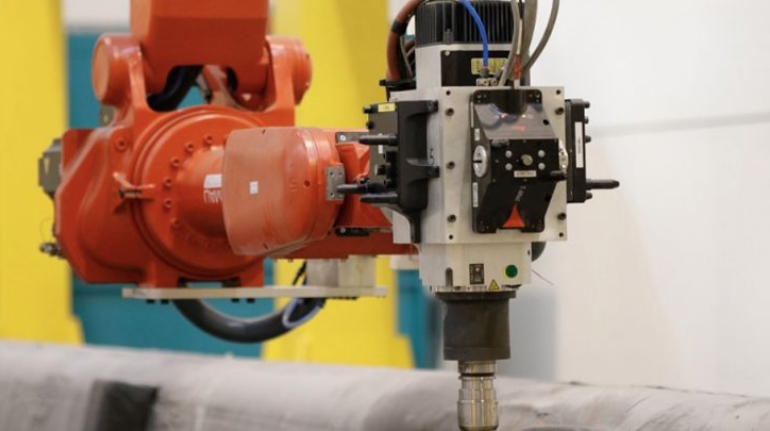

The LulzBot booth at CES 2018 will be a show floor 3D printer factory, using award-winning LulzBot 3D Printers to produce more 3D printers. This unprecedented display will give CES-goers in Las Vegas a first-hand look at how LulzBot 3D Printers are manufactured in Loveland, Colorado, USA with domestic and imported parts. From the 3D printing of specialized components, to final calibration and packaging, the entire process of making a LulzBot 3D printer will happen live. Attendees will have opportunities to win one of the 20 limited-edition Las Vegas-built printers bundled with accessories and filament.