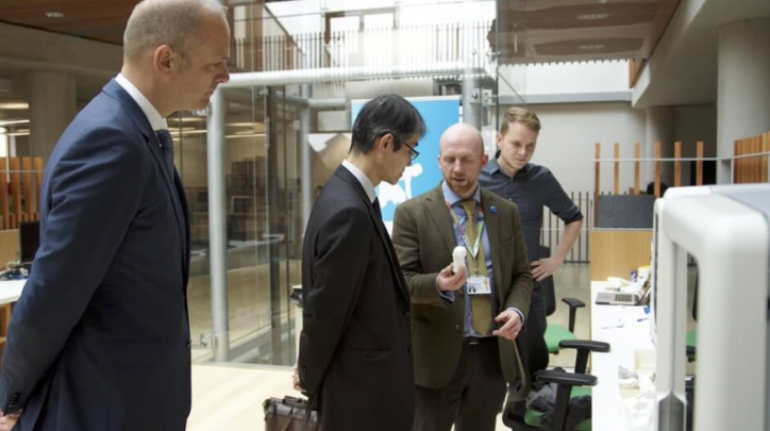

Software Engineer by Day, Handsmith by Night: Meet Lyman Connor | Video Medical

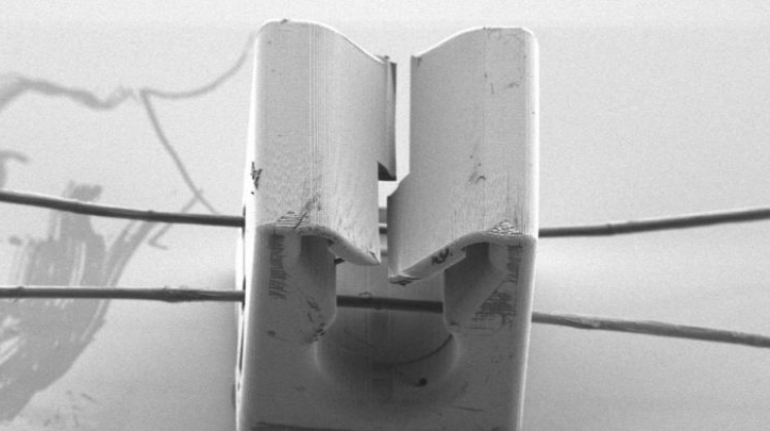

I had the pleasure of meeting and introducing Mr. Conor as a panel speaker during the recent AM Strategies conference in Washington DC. By day he works as a software engineer at General Electric. By night, he builds 3D printed custom prosthetic hands for his Handsmith project. With a small facility of four desktop 3D printers, Lyman has just fit his first patient and moved into production.