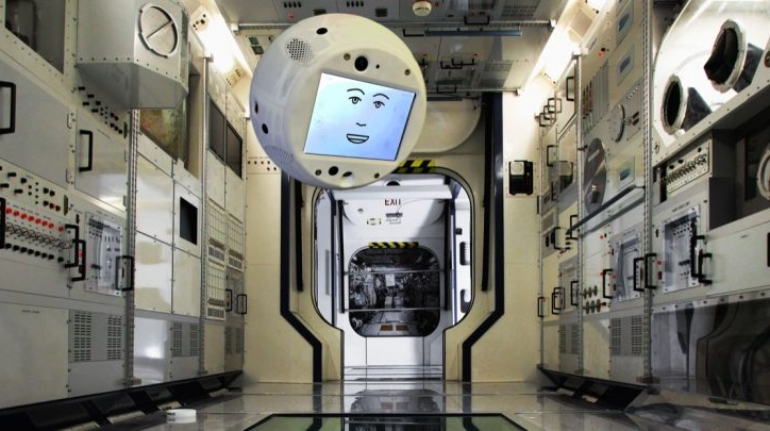

3D printed AI robotic head named CIMON “heads” to ISS Aerospace

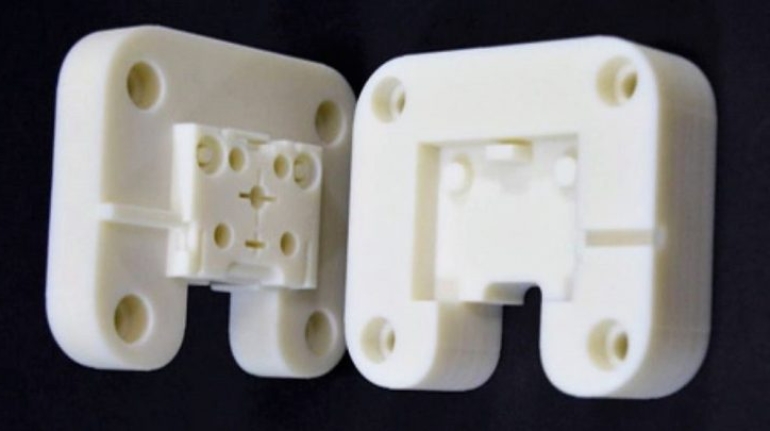

CIMON (Crew Interactive MObile CompanioN), the AI-based assistant for astronauts for the DLR Space Administration, developed by Airbus in cooperation with IBM, took off last Friday aboard SpaceX‘s Dragon cargo capsule and is scheduled to arrive today (June 2nd). Like many unique robots, the technology demonstrator was built using metal and plastic 3D printing processes. It is the size of a medicine ball and weighs around 5 kg. It will be tested on the ISS by Alexander Gerst during the European Space Agency’s Horizons mission scheduled to last through October 2018.