Velo3D releases Sapphire, the first support-free metal PBF 3D printer 3D Printer Hardware

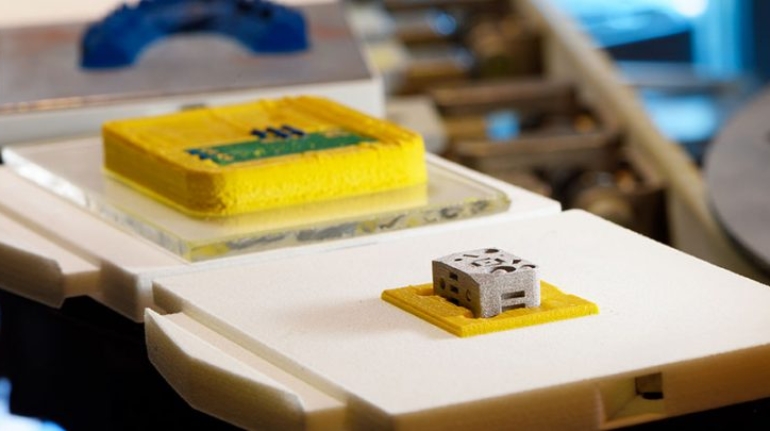

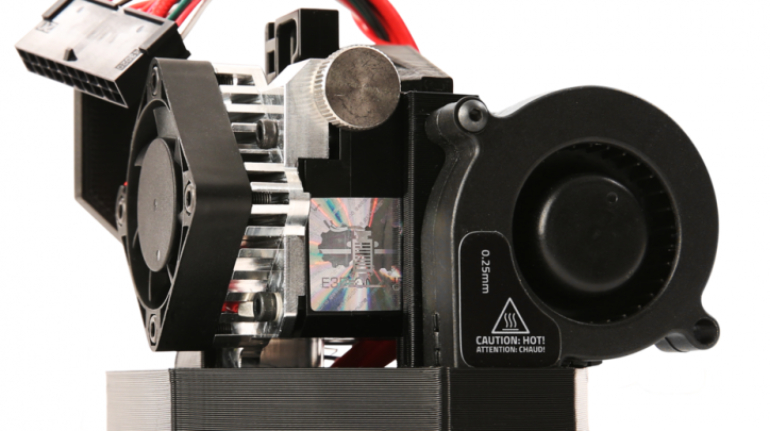

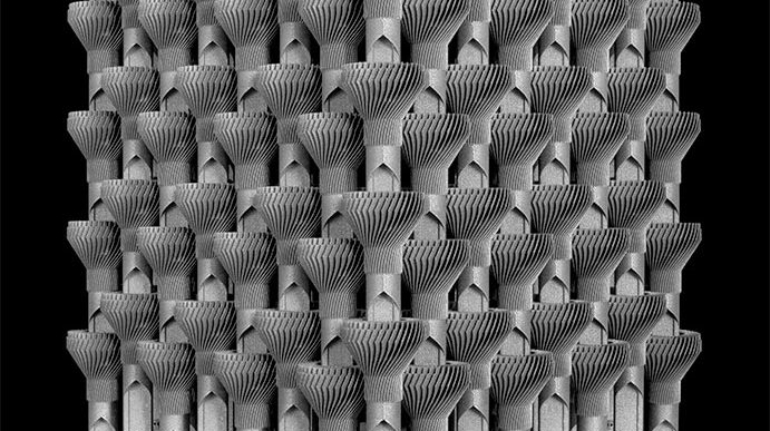

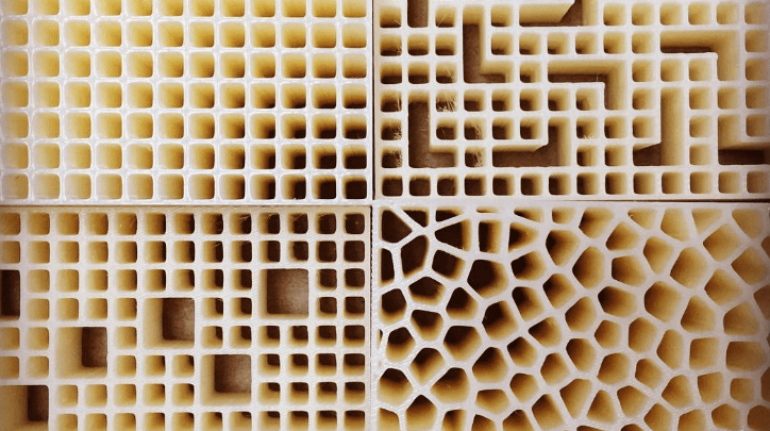

After raising over $92 million in funding, Velo3D today finally emerged from over 4 years of stealth mode operation by releasing its first end-to-end metal additive manufacturing solution comprised. The full package delivers on Velo3D’s announced goal of truly disrupting metal AM in terms of cost and productivity. It comprises the Velo3D Sapphire 3D printer, the Flow print preparation software, and what the company refers to as Intelligent Fusion technology.