Sisma shows off sleek and fast EVERES DLP 3D printers at gala event in Frankfurt 3D Printing Events

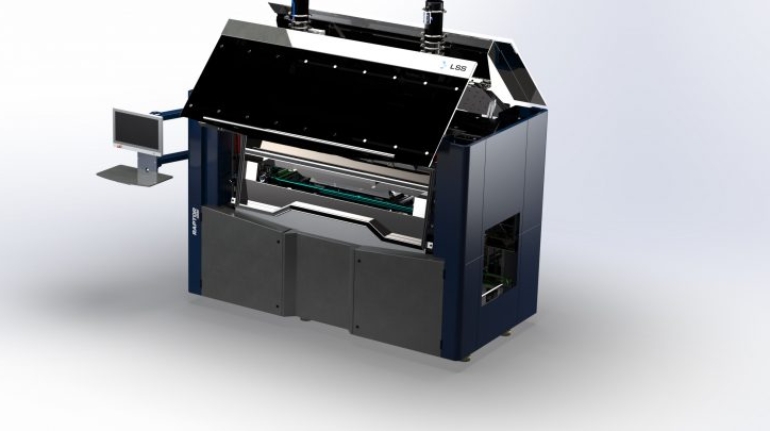

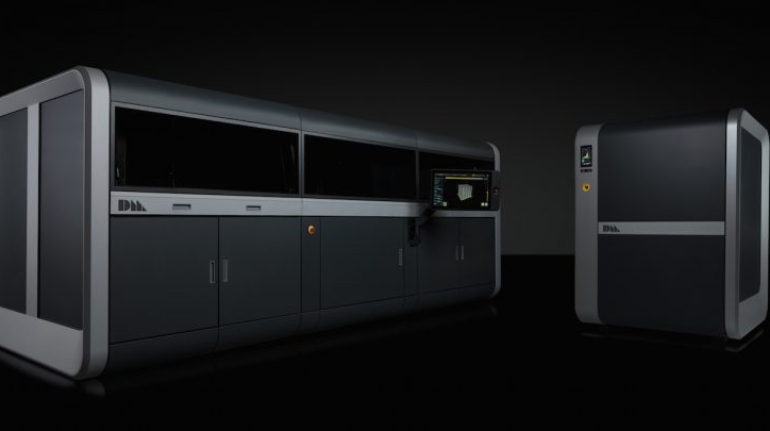

On the evening of day-one at the formnext 2018 show in Frankfurt, Italian high-end 3D printer (and jewelry machinery) manufacturer Sisma invited a select number of journalists and industry players to an exclusive event to present the new EVERES ZERO and EVERES UNO 3D printers.