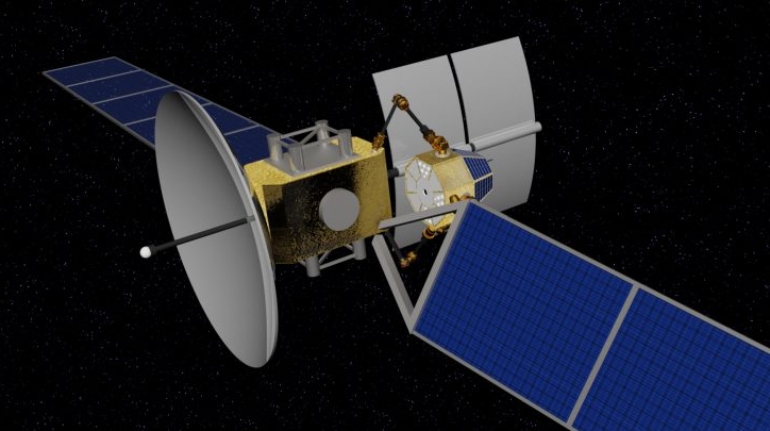

Made In Space achieves significant milestone with Archinaut system Aerospace

Made In Space, the company responsible for sending the first 3D printer into space, has announced a significant milestone in the development of its Archinaut program. The California-based company has successfully demonstrated the Archinaut’s additive manufacturing and robotic assembly capabilities in a space-like environment.