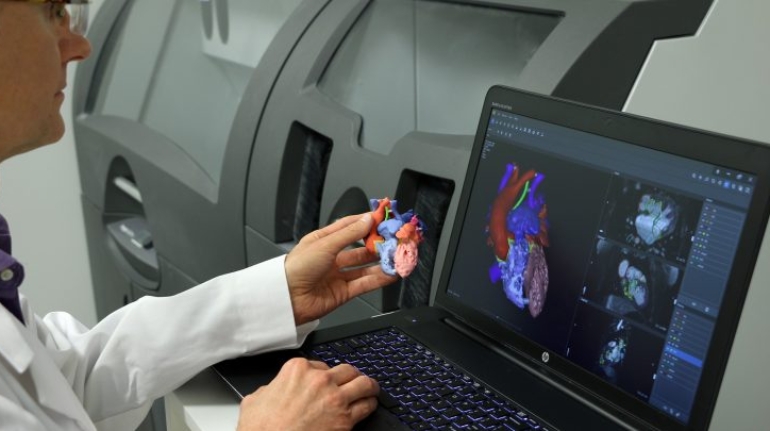

FDA clears 3D Systems’ D2P software for anatomical models Medical

3D Systems has received additional 510(k) clearance for its D2P (DICOM-to-PRINT) software for the medical industry. The software, which enables clinicians to easily 3D print patient-specific anatomical models, works in tandem with 3D Systems’ 3D printers to create models for a range of medical areas, including cardiovascular, craniofacial, gastrointestinal, genitourinary, neurological and musculoskeletal applications.