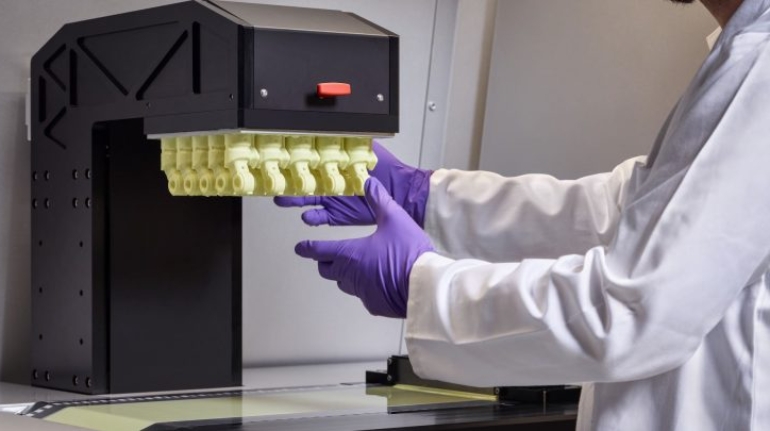

Rapid Shape joins Henkel’s open materials platform AM Industry

German DLP 3D printer manufacturer Rapid Shape has entered into a partnership with materials company Henkel in order to accelerate the mass production of 3D printed functional parts. As part of the agreement, Rapid Shape has become the latest member of Henkel’s open materials platform and will work to certify materials for its DLP 3D printing systems. Henkel, for its part, will integrate Rapid Shape’s technology into its AM ecosystem.