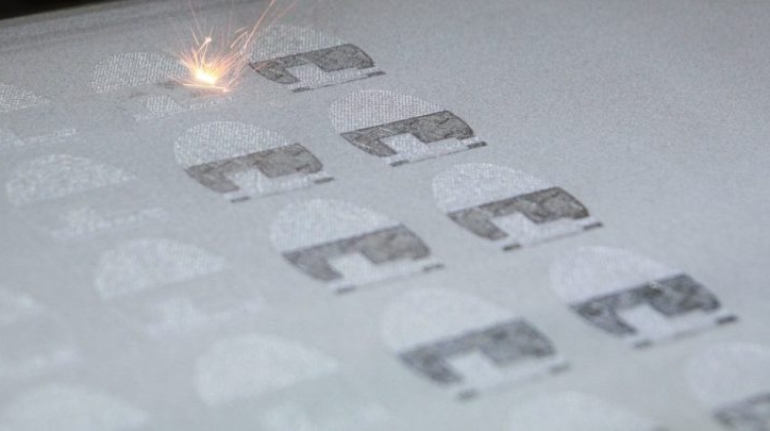

Adiprene prepolymers from LANXESS offer new possibilities in 3D printing Consumer Products

Specialty chemicals company LANXESS is offering the next generation of Low Free (LF) isocyanate urethane prepolymers that can be formulated into resins for 3D printing/additive manufacturing. In order to create such resins, LANXESS works together with 3D printing companies. Based on Adiprene LF pPDI (para-phenylene diisocyanate) prepolymers, these high-performance resins are easy to process and safe for industrial manufacturers as well as for the casual home, office or retail user.