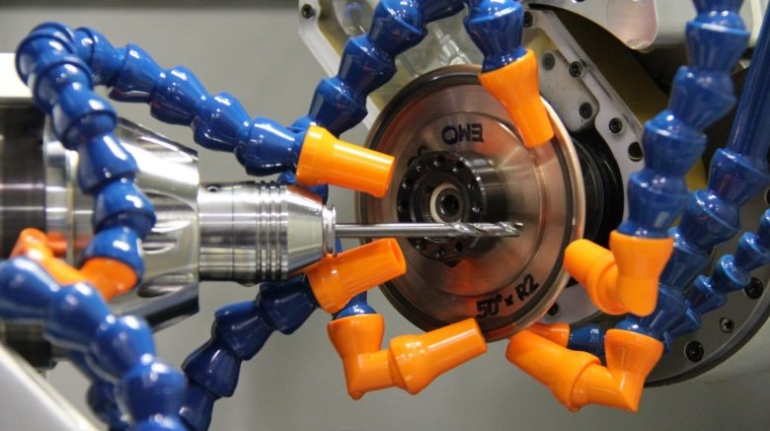

ANCA and CSIRO developing hybrid AM system for tungsten cutting tools Additive Manufacturing

ANCA, an Australian manufacturer of machine tools, is teaming up with national science agency CSIRO, Sutton Tools and the Advanced Manufacturing Growth Centre (AMGC) to develop and bring to market a new hybrid manufacturing platform that combines additive and subtractive capabilities. The new and potentially disruptive system will be designed to manufacture custom cutting tools made from tungsten.