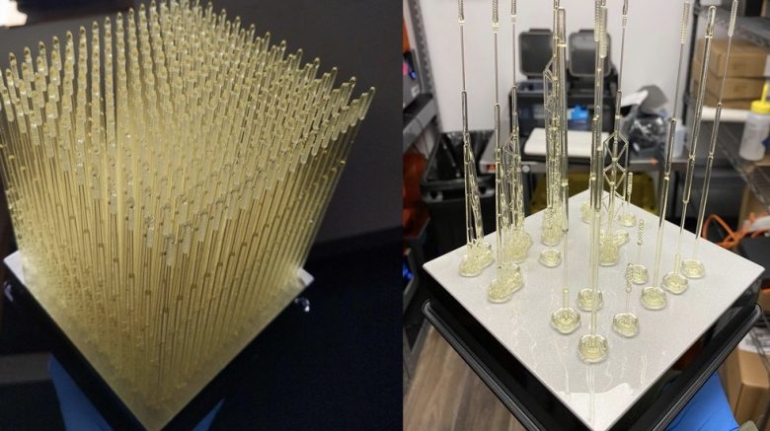

Mimaki launches new Mimaki 3DGD-1800 large format 3D printer 3D Printer Hardware

Mimaki’s 3D printing business has been intertwined with Israeli technologies from the start. The Japanese company is a leader in large format 2D inkjet technology just like many of the firms involved in the evolution of companies like Objet, which later became Stratasys. After launching the only credible material jetting alternative for Stratasys full color 3D printing, now Mimaki Europe closed an OEM deal with another Israeli company, Massivit (whose founders originated from the Objet team), to launch the new Mimaki 3DGD-1800 large format, high-speed 3D printer.