WASP advances Shamballa open-air 3D printing lab Construction 3D Printing

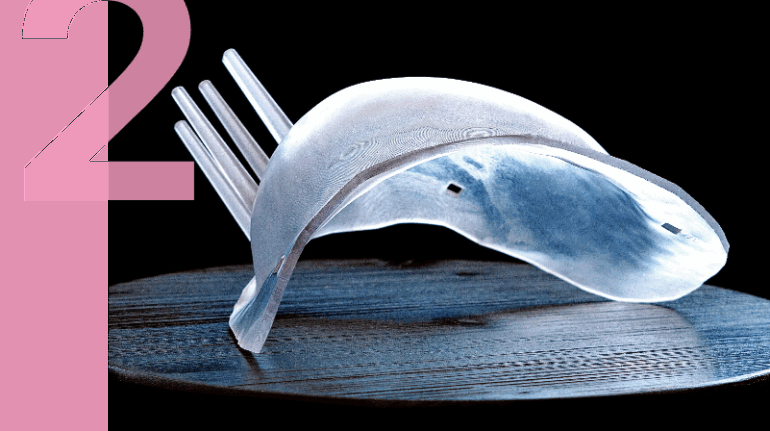

Italian company WASP has become known for its 3D printing hardware, particularly its clay and cement printing platforms that have unlocked numerous creative projects, like a sensory garden and coral reef modules. Some may not know, however, that the company has since its early days been driven by a utopian dream of building Shamballa, a place where 3D printing could be used to build community and provide the fundamentals to human life: housing, food, healthcare, energy, employment and culture.