AM for COVID-19 Forum: let the world know how AM can help locally AM Industry

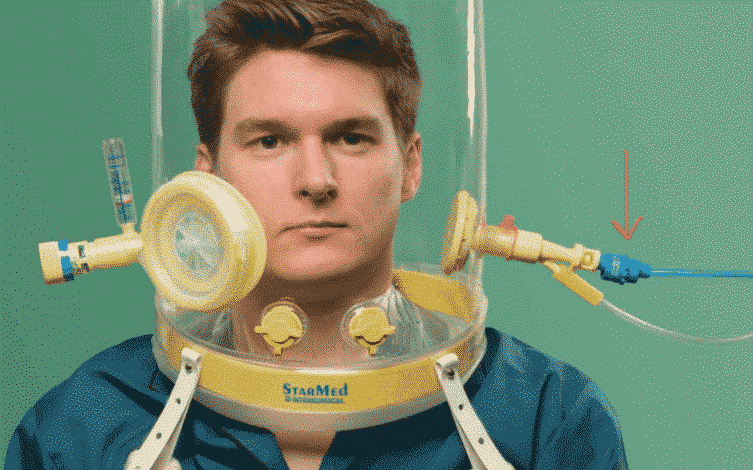

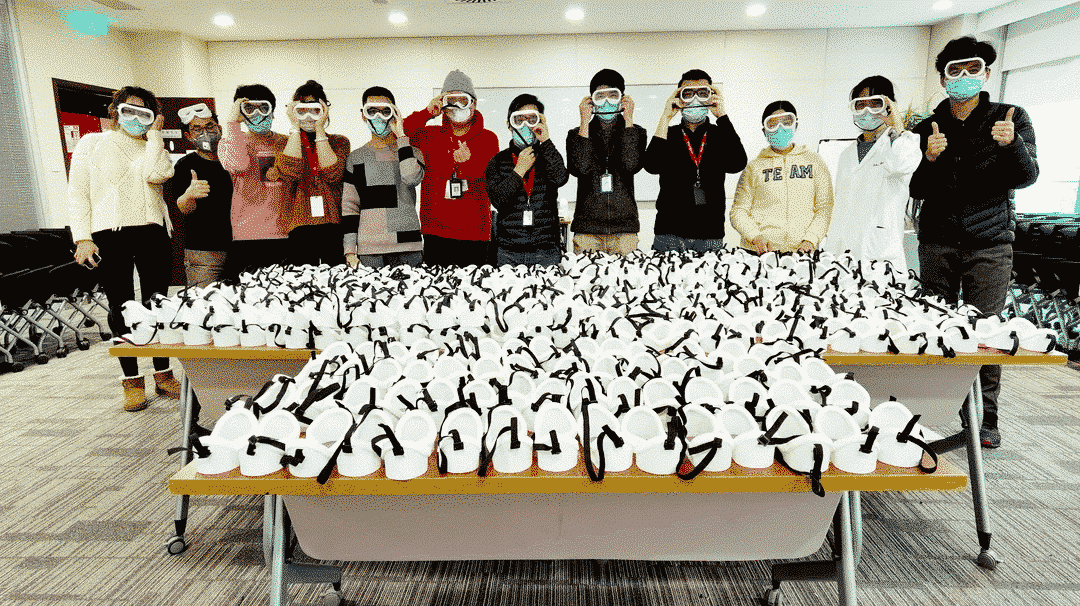

The AM for COVID-19 Forum was launched to enable medical providers to communicate to AM providers what is needed at the front lines. As we’ve seen, the two most critical things needed at this point in time (besides medical staff), are emergency products like mass-produced protective masks and ventilators, which will be needed in mass numbers very soon. While AM is not a technology used for mass production, it has two significant advantages over traditional manufacturing: it can produce locally and can begin production immediately and these are, in any emergency, key advantages.