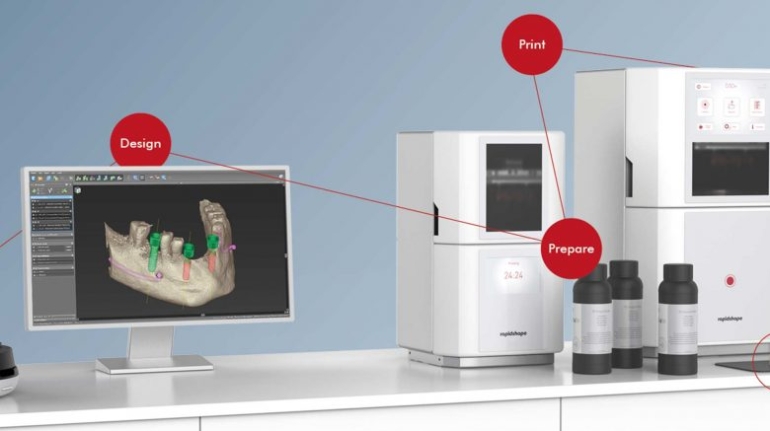

Heraeus AMLOY and TRUMPF advance 3D printed amorphous metals Materials

Heraeus AMLOY, a specialist in amorphous metals, has partnered with machine manufacturing company TRUMPF to advance the 3D printing of amorphous metals. The group of materials, also known as metallic glasses, demonstrate exceptional strength (twice as strong as steel) but with less weight and more elasticity. Through their collaboration, the companies aim to establish additive manufacturing as a standard production process for amorphous metals.