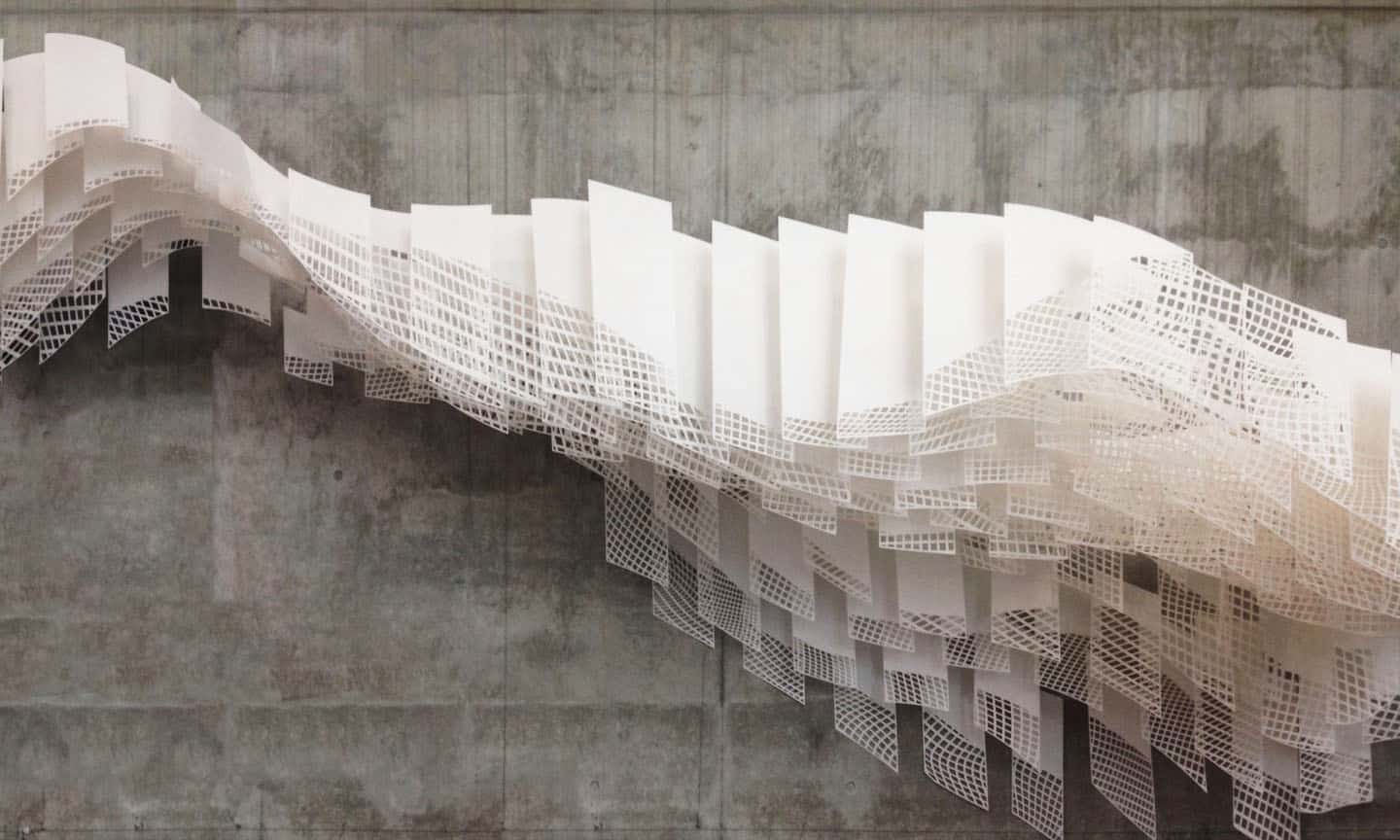

Discover the sand 3D printed Ionic Sound System from Deeptime Consumer Products

Remember the Spirula Speaker by studio Akemake? It was one of the very first design products showing that it was possible to actually make nice, functional finished consumer products using 3D printing. It was made using a wooden-polymer composite filament in a filament extrusion process and it still had limits both in form and productivity. Now that company is called Deeptime and it has evolved to embrace a more production-ready sand binder jetting 3D printing process: the result is the stunning Ionic Sound System, which consists of two passive sand 3D printed Spirula satellites and an active Thunderstone subwoofer (also 3D printed). The Thunderstone has optical, AUX, and Bluetooth inputs and contains the electronics that power the sound system.