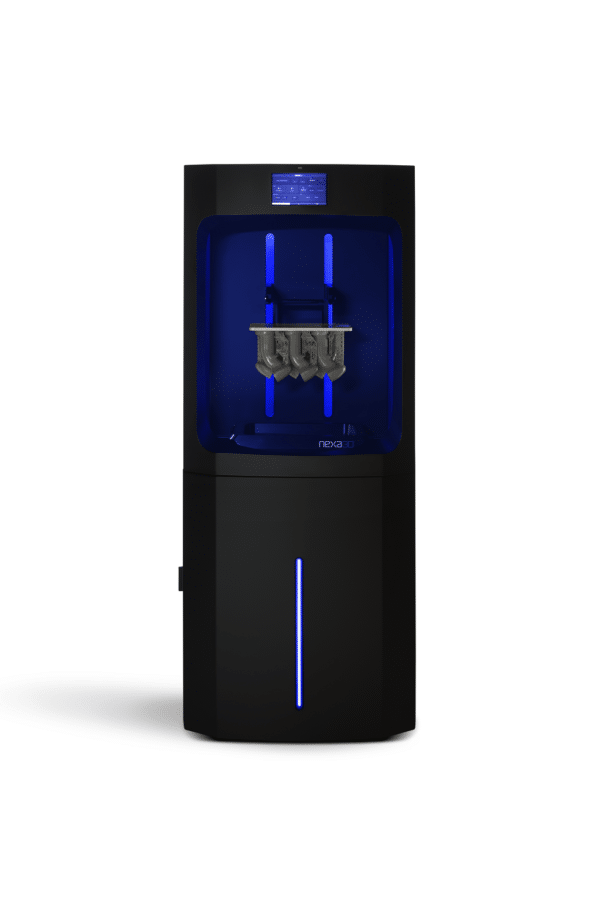

NXE 200 3D Printer with LSPc Technology Launched by Nexa3D

Nexa3D, a maker of ultra-fast 3D printers, has released the NXE 200 industrial 3D printer, an affordable entryway into Lubricant Sublayer Photo-curing (LSPc) technology. The NXE 200 is a natural expansion of Nexa3D’s portfolio, which also currently includes the NXE 400 industrial 3D printer and NXD 200 dental 3D printer, with the intention of broadening LSPc’s accessibility.