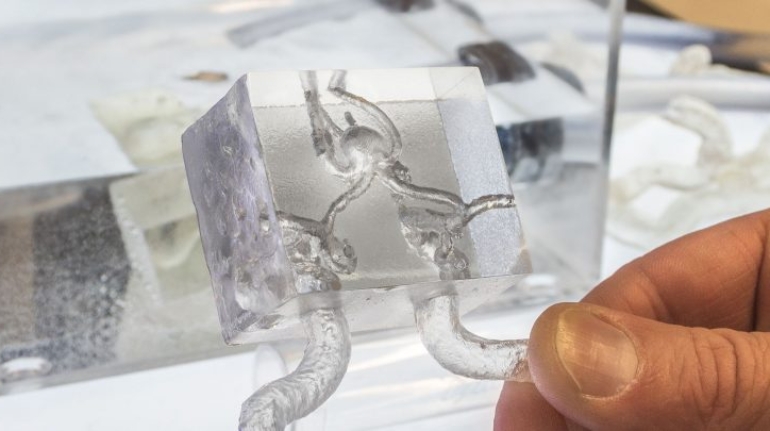

3D LifePrints Now Offers Unparalleled Selection of Silicone 3D Printed Medical Models AM Software

The use of 3D printed medical models for pre-surgical simulation is starting to become commonplace. Exact numbers are not available and it may not be implemented in all hospitals yet, however almost all professionals are now aware of the possibilities and advantages it offers especially in terms of reducing time in the OR and for patient recovery.