Aureal Twist Design Wins WASP 3D Printing Light Contest 3D Printing Events

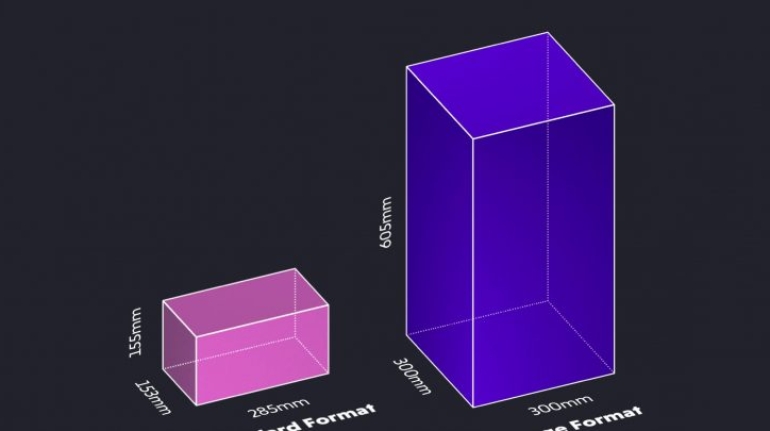

Marco Parnasi, an architect and designer from Florence, Italy, won the 3D Printing Light Contest organized by Italian 3D printer manufacturer WASP and the OpenDot makerspace. His Aureal Twist design will be 3D printed using a large format 3MT system from WASP. The 3D printing will take place during the 999 event, from March 2-4 at the Triennale Design Museum in Milan.