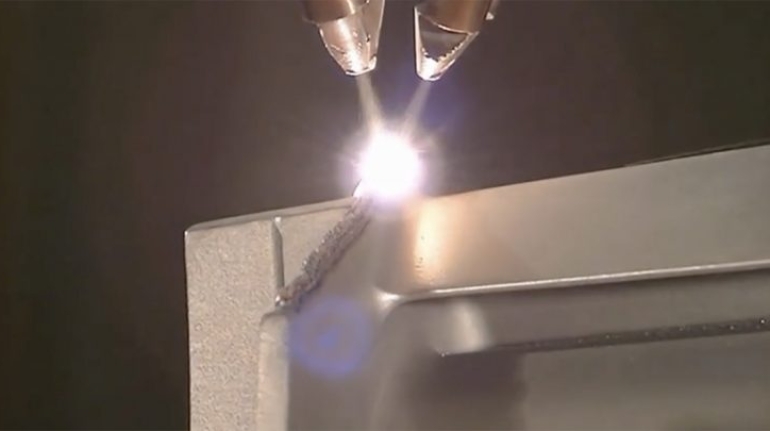

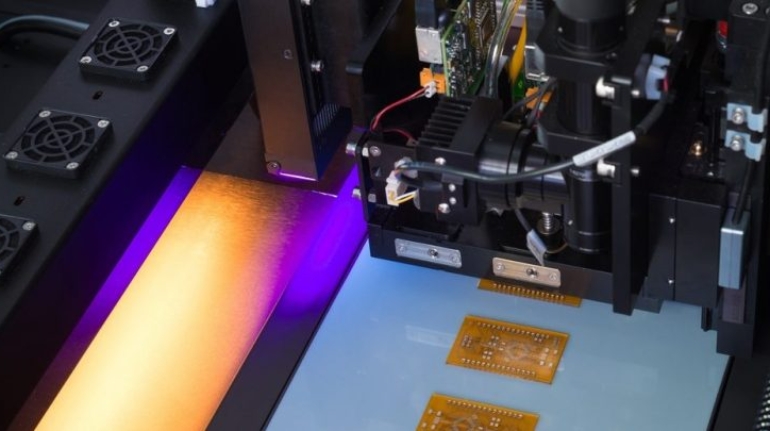

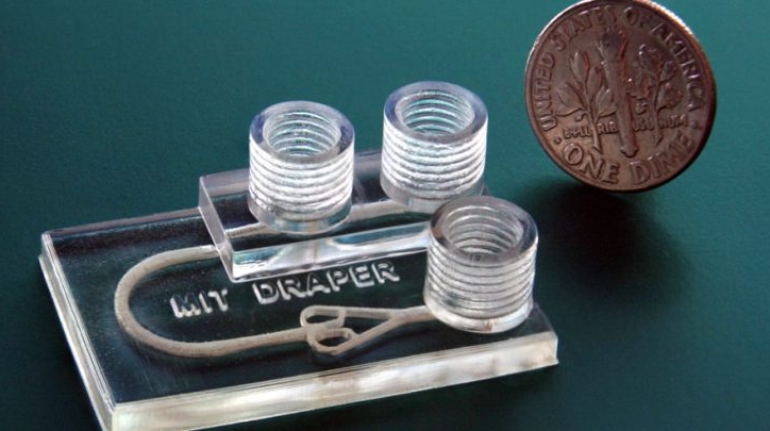

Precision ADM targets production for aerospace industry with new certifications Aerospace

Precision ADM, Inc., a Canadian AM solutions provider based in Winnipeg, has received AS9100 Rev D and ISO 9001:2015 Quality Management System certifications, enabling it to manufacture components for the aerospace industry.