GE Aerospace expands AM production capabilities with 27 new EBM systems Aerospace

GE Additive today announced at the Paris Air Show that GE Aviation has made a significant investment in its electron beam melting (EBM) technology, with the purchase of an additional 17 A2X systems and 10 Spectra H systems. Financial terms of the deal were not disclosed.

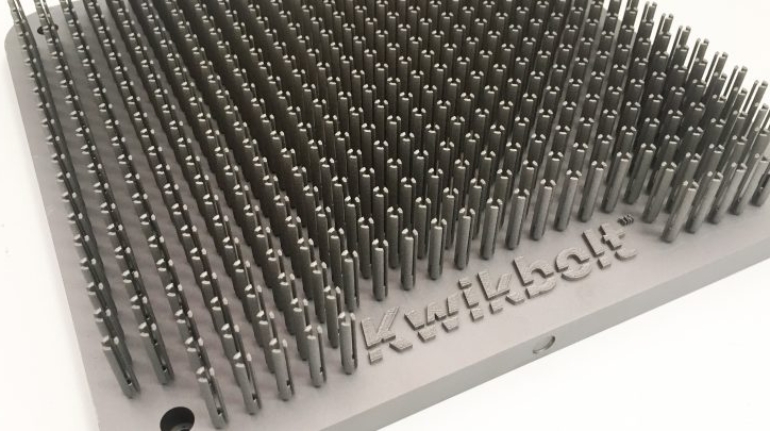

![SPEE3D shows of new, larger WarpSPEE3D cold spray AM system [video] 3D Printing Processes SPEE3D shows of new, larger WarpSPEE3D cold spray AM system [video] 3D Printing Processes](https://facfox.com/wp-content/uploads/orderfile/image/2020/11/yYvuea.jpg)