ActivArmor Brings Custom, Waterproof 3D Printed Orthopedic Devices to Veterans

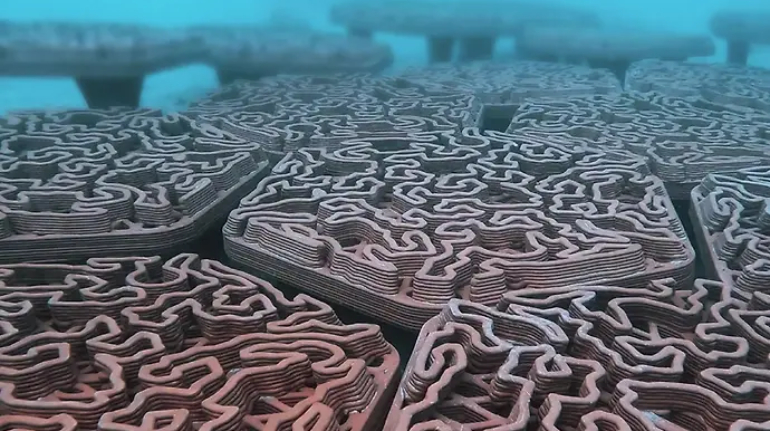

The Atlanta VA Healthcare System (VAHCS) is now the first VA facility to provide advanced 3D printed casts and splints. Using the ActivArmor system, the facility can produce orthopedic devices that are customizable, waterproof, and breathable. These devices support a wide range of services, including Orthopedics, the Emergency Room, Occupational and Physical Therapy, Podiatry, and diabetic clinics.