Rapid Manufacturing AG develops 3D printed glove remover for COVID-19 protection AM Industry

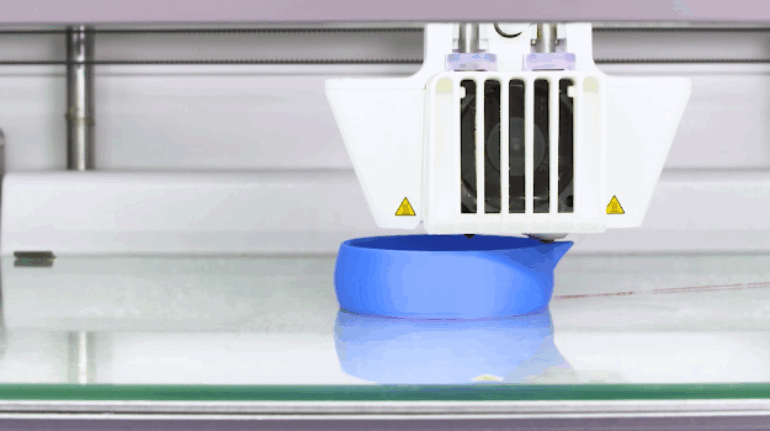

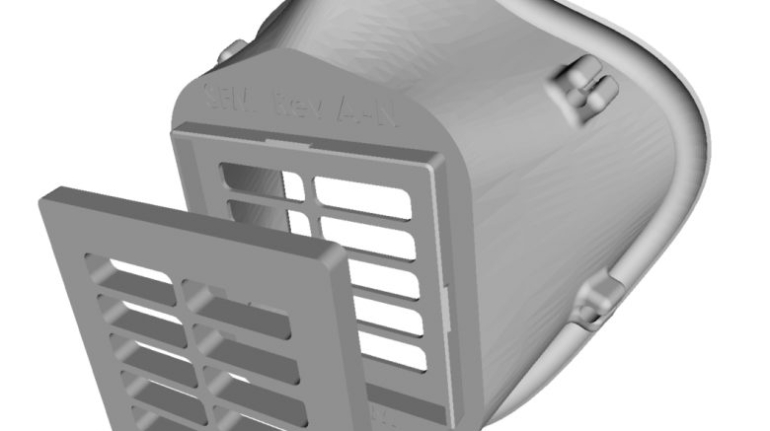

Swiss 3D printing service bureau Rapid Manufacturing AG, together with Swiss creative agency Atoll and Zurich-based Pragma Engineering, developed a simple solution to address the issue of disposable glove removal: a 3D printed glove remover. This is something many of us have become quite familiar with during the ongoing COVID-19 pandemic: personal protective equipment has become part of our daily lives in dealing with the risk of contamination.