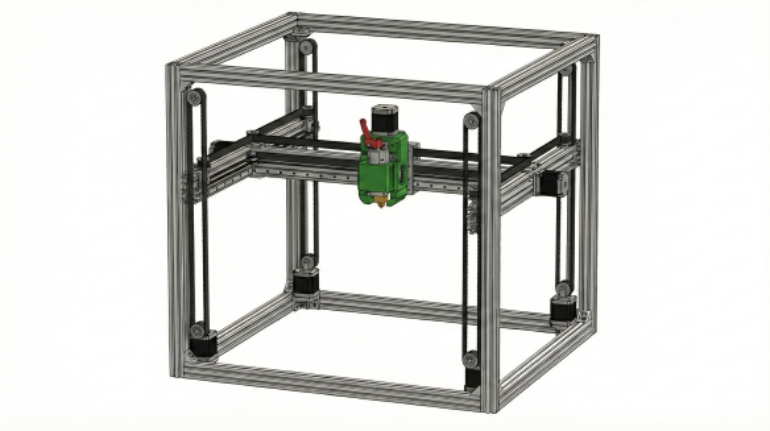

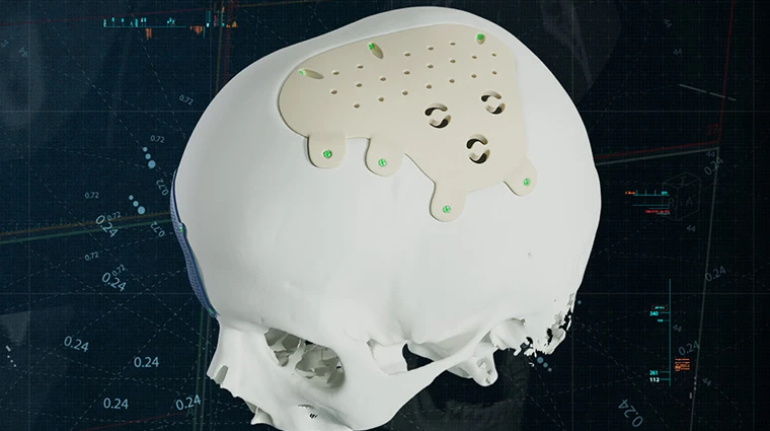

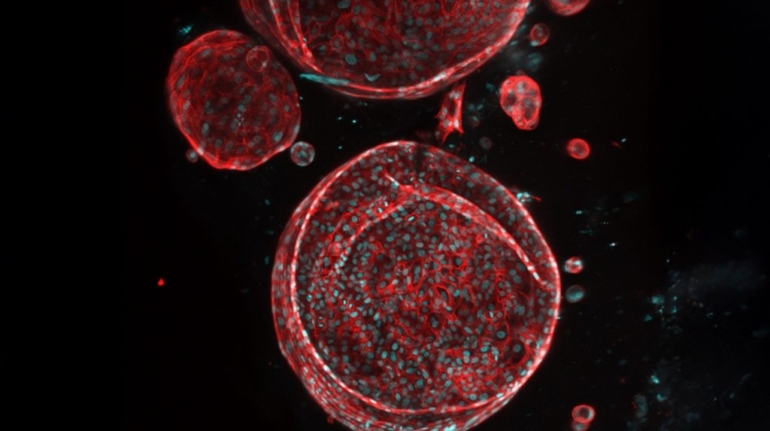

CollPlant targets formulation bottleneck with new DLP bioprinting kit

Regenerative medicine specialist CollPlant has launched BioFlex, a ready-to-print bioprinting kit built on rh-collagen, aimed at researchers working on tissue engineering and regenerative medicine.