Construction 3D printing has long been heralded as a solution for building affordable housing and as the technology has advanced over the years, we are now starting to see that become a reality. The latest news on this front is coming out of Australia, where the government of New South Wales has announced its intention to use 3D printing to address a shortage in housing and build the first 3D printed social housing property in the Australian state.

3D printing can accelerate construction time by 50% compared to traditional building methods and is also substantially cheaper. Both these factors are vital in the establishment of much needed social housing units, as the people of New South Wales face growing challenges when it comes to housing affordability and availability. The ability then to build social housing in 16 weeks rather than 40 weeks will help house people faster in a time of need.

Manufacturing on Demand

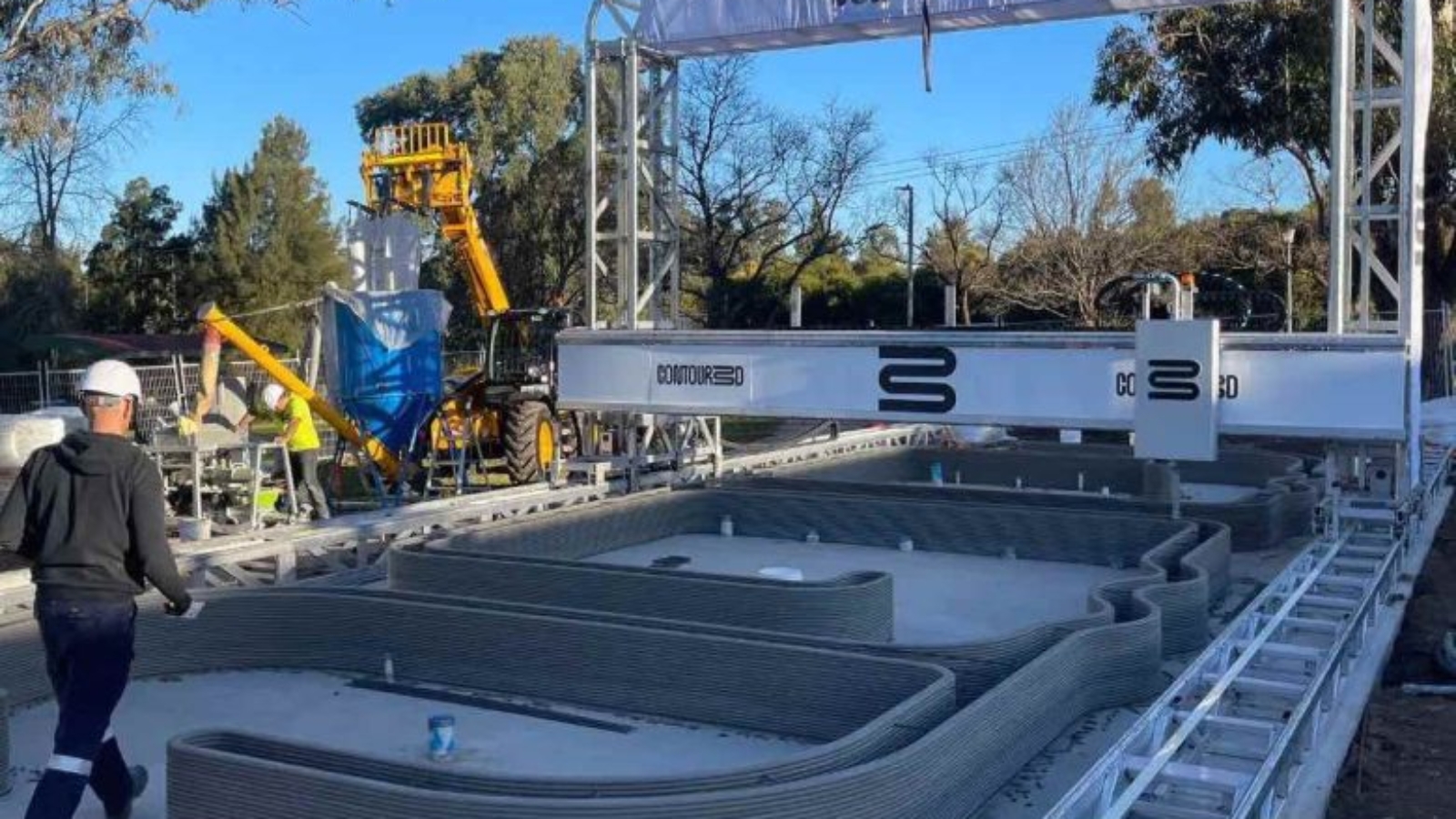

The construction of the social housing property will take place in Dubbo, a city five hours inland from Sydney and will be carried out by Aboriginal Sustainable Homes in partnership with local construction 3D printing company Contour3D. A series of two-bedroom duplexes will be constructed on a vacant lot in Dubbo and will ultimately be offered to tenants through the Aboriginal Housing Office.

The social housing project is expected to break ground in late September 2024 and will rely on Contour3D’s gantry-based construction 3D printing solution, which has already been used to build a one-bedroom home in Gymea Bay, NSW, which was recently awarded a full occupancy certificate. “We’re excited to showcase our innovative building method that prioritizes sustainability, design freedom and efficiency by bringing automation to the forefront of housing construction,” said Contour3D founder and CEO Nick Holden about the upcoming build.

Rose Jackson, the Minister for Housing and Homelessness, also commented on the innovative project: “Utilizing Modern Methods of Construction like this 3D printing technology is critically important to delivering social and affordable homes sooner, especially in regional and remote areas. Our government is leading the way with this project. The construction of a 3D social housing property is the first of its kind in the country. For it to be led by the AHO reflects their dedication to exploring new and efficient ways of building more quality homes for community. The success of this project will help to determine whether this construction method becomes one of the many ways we can deliver more social housing right across the state in a bid to help us tackle the growing crisis.”

You might also like:

Omantel partners with Innotech to 3D print artificial reefs in Oman: The 3D concrete printing technology enables the design and customization of reef structures, including complex features like crevices, caves, and ledges that enhance fish populations by providing shelter, and feeding grounds. The new initiative aims to increase fishery yields, promote sustainable fishing practices, promote marine biodiversity, and boost the local economy.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Tess Boissonneault

Leave A Comment