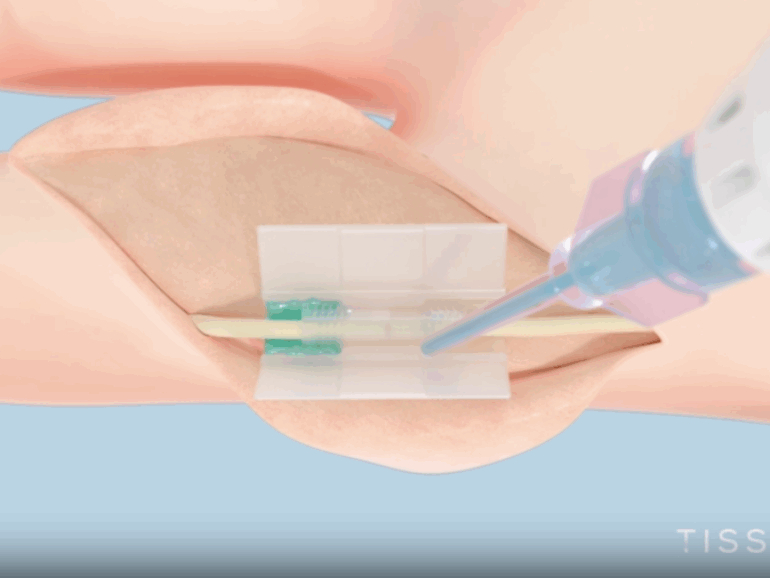

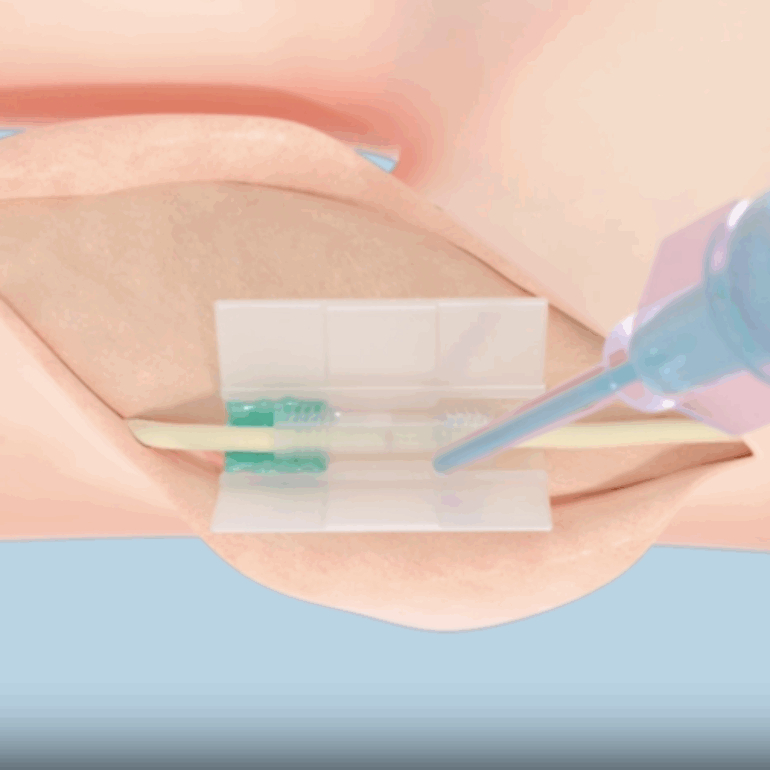

3D Systems and TISSIUM Receive FDA Approval for First-of-its-Kind Peripheral Nerve Repair Device

U.S.-based 3D printer manufacturer 3D Systems, in partnership with French MedTech firm TISSIUM, has secured FDA approval for a bioabsorbable, 3D printed device designed to treat peripheral nerve damage. This approval validates the polymer’s clinical effectiveness and paves the way for its use across a wide range of medical treatments.

Dimension Ortho Partners with Rothman Orthopaedics to Advance Personalized Fracture Care

Dimension Ortho, a provider of 3D printed orthotics, has entered into a partnership with Rothman Orthopaedics, a major U.S.-based orthopedic practice recognized for its work in musculoskeletal care. This collaboration will enable Rothman to implement Dimension Ortho’s platform for customized bracing and fracture care across its clinical network, with the goal of elevating patient care standards.

Ricoh launches Ricoh 3D for Healthcare, LLC to accelerate patient-specific device adoption

Ricoh USA, the North American arm of the Japanese digital services multinational, has announced the formation of Ricoh 3D for Healthcare, LLC, a new legal entity dedicated to delivering FDA-cleared, patient-specific 3D printed medical devices at hospitals across the United States. The company, unveiled on June 17, 2025, will enhance Ricoh’s ability to meet growing clinical demand for personalized care, streamline regulatory compliance, and support point-of-care manufacturing.

3D Printed Motor Neuron Organoids by Uppsala Researchers Could Accelerate ALS Drug Development

Researchers at Uppsala University in Sweden have developed 3D printed models from patient-derived cells to simulate motor neurons in the lab. These structures, known as motor neuron organoids, are expected to support research into neurodegenerative diseases such as Amyotrophic Lateral Sclerosis (ALS) and help explore treatment strategies without the need for invasive procedures.

Construction 3DP central to Canadian Indigenous housing project Construction 3D Printing

In Canada, Indigenous communities face a serious housing crisis, with the Assembly of First Nations reporting that well over 150,000 new homes are required in order to begin to close the housing gap. To help address this urgent need for housing, Toronto-based real estate developer Horizon Legacy has teamed up with Two Row Architect, a native-owned firm from Six Nations of the Grand River reserve in southern Ontario. Together, the partners are breaking ground on a new construction project that will use robotic 3D printing technology to build a three-story residential building.

United Utilities pioneers 3D printing adoption for water infrastructure Industrial Additive Manufacturing

United Utilities, a British water supply company, is progressing its plans to adopt 3D printing methods across its AMP8 delivery and daily operations. The move comes as the trailblazing ‘Water Industry Printfrastructure’ (WIP) project reaches its conclusion after two successful years during which several industry firsts have been achieved. Funded through Ofwat’s Innovation Fund, the project was led by United Utilities, in partnership with tech innovators ChangeMaker3D, Manchester Metropolitan University’s (MMU) PrintCity, and Scottish Water.

ICON 3D prints homes for Texas A&M AgriLife Research students Construction 3D Printing

Texas A&M Agrilife Research, QuadTex, and ICON, a leading construction 3D printing company, have recently completed three 3D printed homes for student housing in McGregor, Texas. The 1,197-square-foot homes will provide housing for students participating in agricultural research and technology innovation at the Texas A&M AgriLife Research station in McGregor.

3D printing helps restore face of a 75-year-old cyclist at new NHS Bristol facility

Secure your spot now for exclusive AM insights at our Additive Manufacturing Advantage online conference covering aerospace, space, and defense!