Apis Cor is the first construction 3D printing pure player to receive official Regulation A+ qualification by the SEC to begin offering shares to both accredited and non-accredited investors. Regulation A is an exemption from registration for public offerings with two offering tiers: Tier 1, for offerings of up to $20 million in a 12-month period; and Tier 2, for offerings of up to $75 million in a 12-month period.

“We are so pleased to reach this milestone in our journey to revolutionize the construction industry,” said Anna Cheniuntai, CEO and Co-Founder of Apis Cor. “We have dedicated a lot of time and effort to not only developing this tech but also to provide people with the opportunity to join us in reimaging how construction works. We’re doing that through education, awareness, accessibility to 3D-printing knowledge, and investment opportunities. 3D-printing the walls of a building is only the beginning. We are now poised to lead the way in an estimated $16.6-trillion-dollar industry.”

Manufacturing on Demand

The company made international news for building one of the very first 3D printed houses, in Russia, and later when it secured the Guinness World Record in Dubai for the largest 3D printed building on Earth. The company has since gone on to refine that technology for practical construction applications and tested it on several pilot projects in the USA. Recently Apis Cor opened a showroom in Florida, to display construction 3D printing capabilities and possibilities. The Regulation A+ listing marks a new milestone and industry first.

“I will be working hard and efficiently for the best benefit of the current and future shareholders as well as our customers,” Nikita Chen-iun-tai wrote on his LinkedIn feed. “Thanks to everyone who has been believing in us! [The] next milestone is to get listed on Nasdaq in 3 years.”

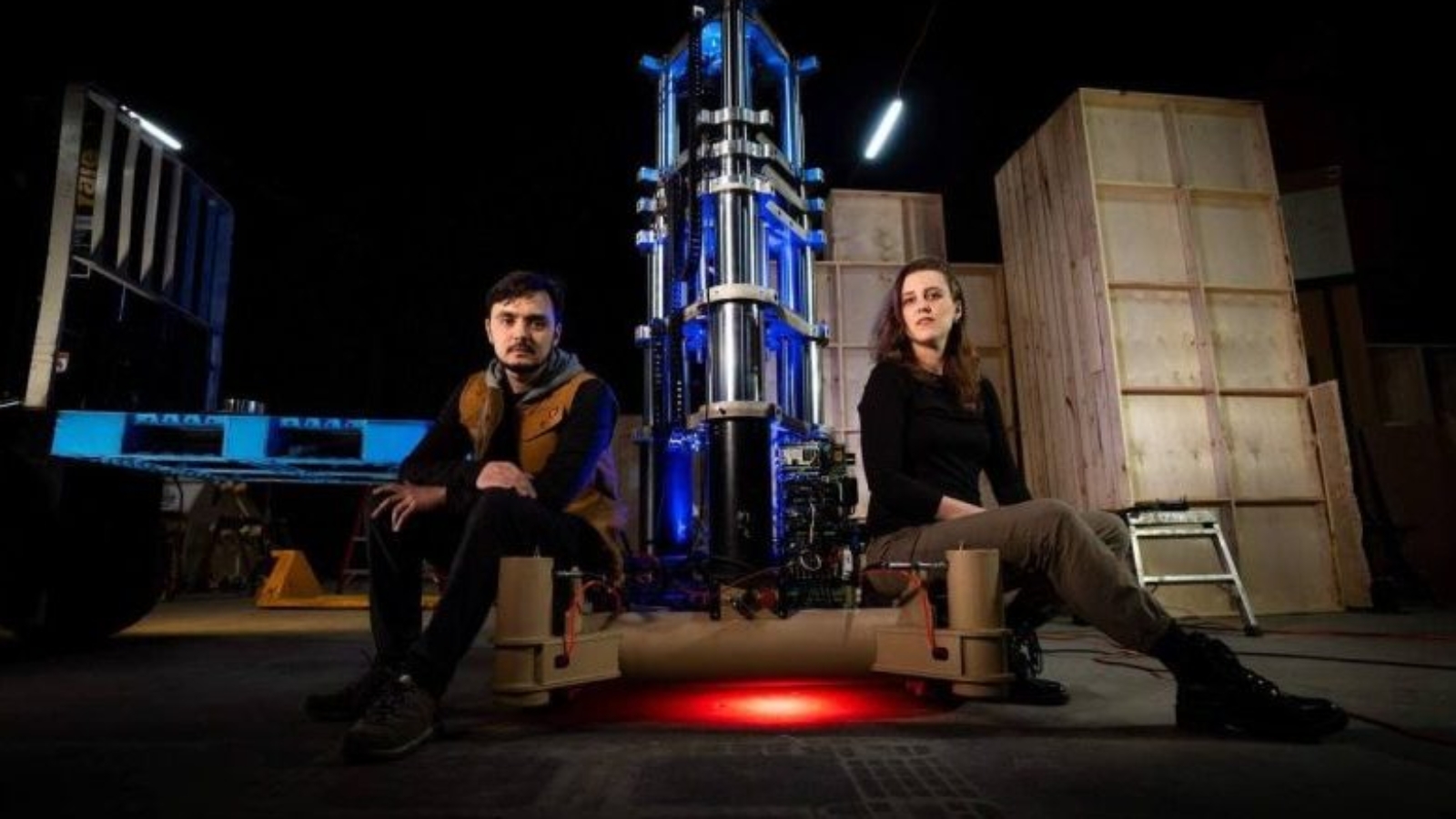

Apis Cor offers a variety of products and services related to the 3D printed building industry, including 3D printing robotic equipment and hardware, available for leasing to construction companies, and fully finished 3D printed homes available within the United States. The company is currently taking reservations with construction to begin in 2023.

The Apis Cor University offers online courses centered on emerging technology along with in-house seminars and training workshops developed to help engineers and construction workers get familiar with the equipment and learn the process of 3D printing a structure.

“We are passionate about developing more technologies and solutions to expedite the entire construction process – just like Henry Ford did by automating the car manufacturing business,” said Anna Cheniuntai. “We’ve been refining the process, fighting to reclaim seconds, then minutes from the overall construction time – leading to increasing gains. We’re working to shave months and years from typical construction times to help people who are most at need for housing – people who can’t afford to wait. And we’re creating fully autonomous equipment that can print buildings on Earth and beyond. The Construction Revolution has begun…”

You might also like:

COBOD 3D prints live at World of Concrete 2022 in Las Vegas: To demonstrate the market readiness of the technology and its widescale applicability in the US, COBOD brought its printing system at one of the largest US construction events. COBOD’s printing system is capable of printing with mortars as well as being the only printer in the world to print real concrete. At the World of Concrete, the COBOD BOD2 printer used a mortar mix from QUIKRETE and demonstrated continuous 3D printing of a wall structure over 3 days in a row increasing the height daily, and during printing, the crowd had the opportunity to ask questions and get explanations to various aspects of the printing process.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment