This year, Hanbang Technology introduced a new technology called Laser Additive & Cutting Manufacturing (LACM), which combines selective laser melting and ultra-fast (eg. picosecond, femtosecond) laser With the combination of cutting technology, the ultra-fast laser is used to refine the contour of the part after each layer is printed, thereby directly producing parts with high surface quality. This is another new technology integration following the hybrid manufacturing of 3D printing and traditional mechanical subtractive materials.

The focus of our introduction in this issue is on the technological effects and potential applications that can be achieved by the combination of SLM and ultrafast laser cutting technology.

Application background and form of mixed manufacturing of additive and subtractive materials based on SLM

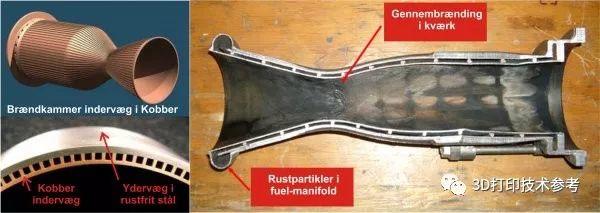

Even though SLM is already a process with high accuracy and surface quality in all-metal printing, for many applications, the surface of the parts printed by SLM is relatively rough, and often requires secondary processing to obtain a high-precision surface. For parts with complicated internal flow channels, such as conformal cooling water channels, ramjet engines, and rocket engine regenerative cooling flow channels, it is difficult to achieve effective reprocessing of internal surfaces. At an exchange meeting, the author heard that the relevant personnel of the aerospace system introduced that the structure with internal flow channels manufactured by SLM can only be made up.

This actually puts forward higher requirements on the precision and surface quality of SLM manufacturing, and there are not many known brands of SLM-based additive manufacturing equipment for mixed materials, and it is rare in China. The organic integration of CNC machining and additive manufacturing can realize the simultaneous completion of printing and finishing and surface treatment, which directly brings the improvement of 3D printing accuracy and surface quality.

However, at present, the combination of CNC machining and additive manufacturing is only a form of mixed manufacturing of additive and subtractive materials. Combining ultra-fast laser cutting technology with SLM has become a new exploration. When ultra-fast laser cutting materials, the duration of each pulse interacting with the material is very short, avoiding thermal diffusion, which is a cold machining process, basically eliminating the melting zone, heat affected zone, shock wave, etc. similar to the long pulse machining process Various effects on the surrounding materials and thermal damage, with extremely high processing accuracy.

Compared with CNC machining, ultra-fast laser micro-cutting avoids frequent tool changes and powder contamination, and powder quality problems caused by cutting, and there is no tool wear, which can significantly improve processing efficiency; at the same time, ultra-fast laser cold machining And flexible machining characteristics, avoiding the stress generated during the machining process; in addition, laser cutting has no cutting force, no deformation during processing, and can process fine structures that cannot withstand the cutting force of the tool and structures that are limited by the size of the tool. Achieve higher manufacturing requirements.

Realize high precision and high-quality metal 3D printing

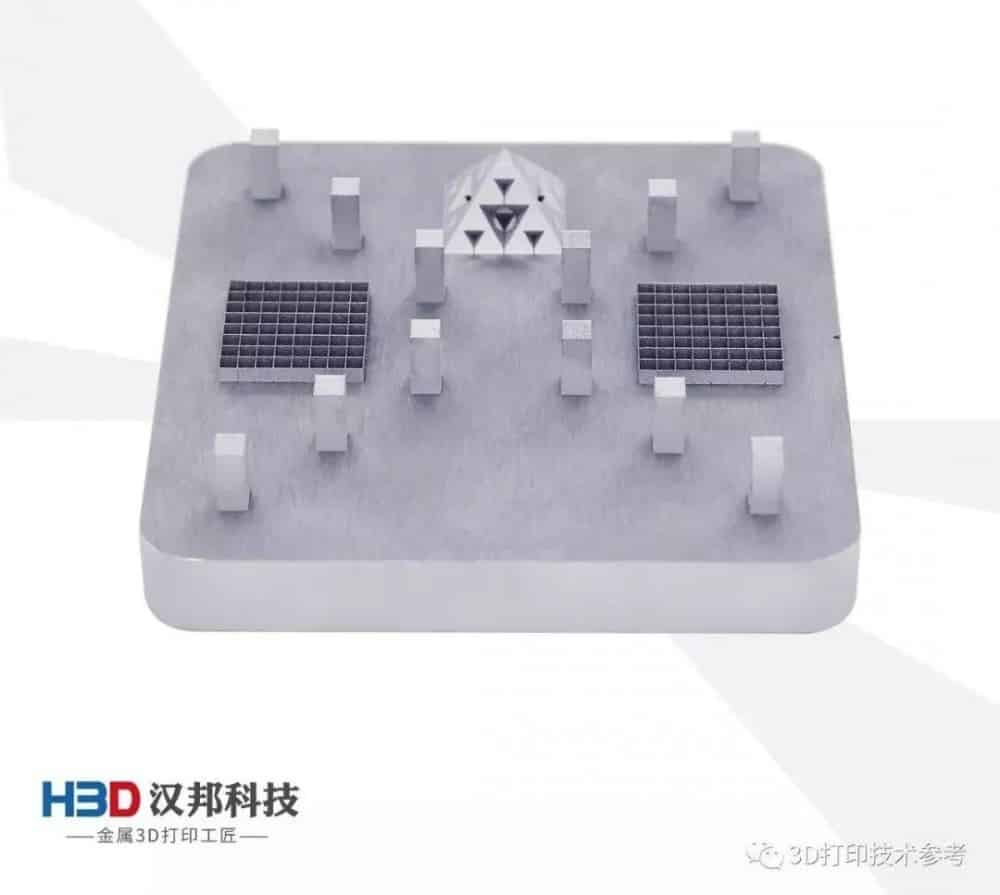

Laser additive micro-cutting metal 3D printing hybrid manufacturing technology can theoretically achieve higher precision and can manufacture very thin metal parts. According to the introduction of Hanbang Technology, using 100 * 100 * 100mm printing equipment, the LACM process can control the precision of parts forming within 0.02mm, the minimum forming wall thickness reaches 0.08mm, and the typical roughness can also be controlled at 3μm. It can be used directly without post-processing or after simple processing. The author of this data has also repeatedly checked with the relevant person in charge.

Good surface quality is bound to meet more application requirements. According to the introduction of Hanbang Technology, LACM technology can be effectively used in the manufacturing fields of precision molds, medical dental implants, precision lumen terminal parts and microstructure parts in the future.

The hybrid manufacturing method that combines additive manufacturing with ultra-fast laser cutting is rare in the international context. The more famous is that in 2017, the US PolarOnyx company used femtosecond lasers for both additive and subtractive materials. Proprietary technology provides opportunities for many fast-growing industries such as aerospace, defense, biomedicine, sensors, and communications.

In addition, the general manager of Hanbang Technology mentioned that the company’s laser additive micro-cutting technology has been developed from 2013 to the initial application of the product, and it has gone through 6 years. . The author believes that for the technology itself, the combination of the two technologies is very novel, but how to make the ultrafast laser play a more significant role and achieve better surface quality may require more exploration. We expect Hanbang Technology to continue cultivating this technology and develop more innovative applications.