With the rapid development of 3D printing technology, the question that seems to be bothering couples and leading to indecisive battles will be “What should we print for dinner?” Within a few years. The Israeli company Redefine Meat was founded in 2018. The company launched “Alt-Steak”. Its appearance and taste are similar to the real ones. This year it will be popular in Israeli restaurants.

Redefining meat can indeed define meat. The company said that with the help of advanced 3D printing technology, it can produce sustainable, high-protein, cholesterol-free steaks.

From laboratory to restaurant

Eshchar Ben-Shitrit, who founded the company (originally called Jet Eat), said as early as 2018 that this announcement “marked the beginning of a new alternative meat product. “We are actually printing steaks,” he said. “We There is a product. This is something we have been doing in large numbers. ”

Beef will be tested in some high-end restaurants in Israel later in 2020. The product will be provided as part of the chef’s dishes, and after receiving high levels of feedback, it will improve 3D meat printers and production-grade chefs and butchers who substitute meat recipes.

Its charm lies in technology

The company has developed a patented technology that can use plant-based recipes to 3D print meat substitutes. It actually uses “ink” to “print” the steak, which is made from soy and pea protein, coconut fat and sunflower oil, natural colors and flavors.

Ben-Shitrit said in a telephone interview with The Israel Times: “This is very unique to us; we are the only ones doing this. We are very close to the composition of meat in nature, and our 3D printers are essentially Like a very complex robot who knows how to ingest each of these ingredients in a very precise way…to make food.”

Master food engineering

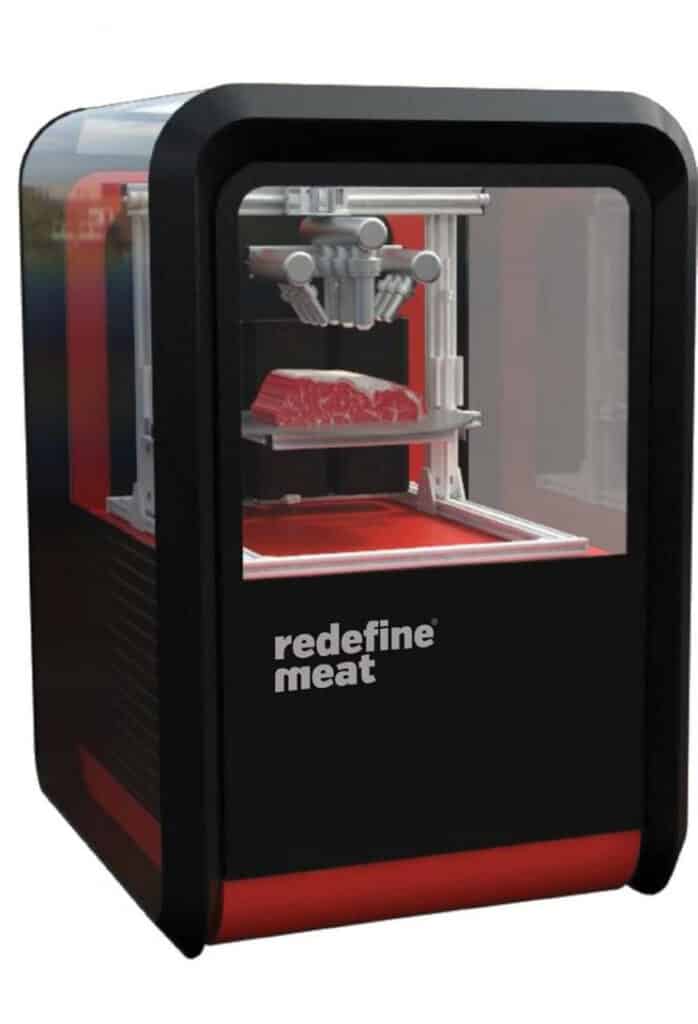

The vegetable product is mixed with water and placed in three ink cartridges. These ink cartridges are built into their 3D printers, as large as large refrigerators.

After the materials are processed in the food engineering in the printer, the machine will eject the product and print out a mixture of fat, blood and meat to produce a muscle structure similar to that of cattle.

Ben-Shitrit said that the machine “prints a dot on a dot, and the product is built with nearly a million dots.” The software can determine the type of steak printed by the printer.

He said: “By using formulas for muscle, fat and blood, we can focus on all aspects of creating a perfect alt-steak product. This is unique to our 3D printing technology and allows us to achieve unprecedented control .”

As of now, each machine can produce 6 kg (13.3 lb) per hour, and will eventually reach 200 kg of meat per day.

The company’s main goal is not to produce vegan dishes, but to disrupt the global food supply chain, as it is well known that meat production has a negative impact on the environment.

The 3D printing revolution may eliminate the need to obtain meat from cattle and provide a new, more sustainable way to enjoy meat in the future.